CENTRIFUGAL PUMPS

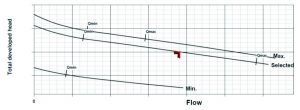

Schematic performance curves for a pump, as

well as maximum and minimum impeller. The

selected operating point is at the left side of the

best efficiency point (BEP). The curve is extended

to about 145% of the BEP flow. The selected

impeller is one size below maximum for the pump

casing. The best kind of curve for evaluation is

one where minimum and maximum flow are

shown together, and where the curve is extended

to show potential performance for the shutoff and

the end of the curve[/caption]

Centrifugal pumps are widely used in many pumping applications. Those driven by low and medium sized electric motors, say 30 to 500 kW, are major workhorses in many industries. Larger pumps of 1 MW to 2 MW might also be used in special services. Such pumps should be operated, most of the time, near their best efficiency point (BEP), although transient operation at all points of the operating curve might be possible at any time. Operation at around BEP will guarantee efficient performance, optimum energy costs, minimum loads on pump components and high reliabilty

Pump Selection

Centrifugal pumps should be used whenever possible. However, there are applications such as dense liquids, high viscosity oils and sludge services where the application of centrifugal pumps is not possible. In those cases, positive displacement pumps should be used. Horizontal centrifugal pumps are preferred and should be used unless suction conditions, space limitations or other operational issues prohibit their application. Vertical pumps can be applied for specific applications such as sump services, low Net Positive Suction Head (NPSH) applications where all attempts have been exhausted, where space limitations are a major consideration or similar reasons where horizontal pumps cannot be used.

The right pump should operate stably at any point on its curve; but should generally be ran at or close to its BEP. However, there is always the possibility of temporary operation at the far left (near shutoff) and the far right of the curve. Therefore, pump selection should verify stable operation at any point on the curve.

A pump driver should be chosen that is non-overloading over the whole range of the pump curve. All potential variations should be taken into account during the selection process such as using the largest possible impeller with the selected pump casing. The density and temperature variations of the fluid being pumped also have to be considered. Be aware, though, that some pump manufacturers cut the pump curve (especially at the end of the curve) to reduce driver size. In other words, some vendors do not show the extension of the curve at the far right side.

As a rough indication, the pump curve should be extended to somewhere between 125% and 160% of BEP capacity (depending on pump details). It is known that some special low specific-speed pumps cannot achieve 125% of BEP flow; however, in those rare cases, vendors should be asked to clearly prove the limit, not grossly cut the curves. The pump operating point should be selected to the left side of BEP. Preferably, it should be selected in the range of 75% to 110% of BEP capacity. For some pumps, efficiency drops of rapidly at left or right side of the BEP. Therefore, operating points close to the BEP should be selected. As a rule of thumb, efficiency at the operating point should not be less than 5% below BEP efficiency.

Additionally, centrifugal pumps should be selected for the calculated pump head without the addition of safety factors. In other words, if a few percent higher head is needed during operation; it will be provided by a slight movement in the operating point on the pump’s curve. Shut-off head should preferably be 12% to 25% above the rated head. The first option for any pump service should be the 1+1 configuration. This means one operating pump and another immediately available on standby. Multiple pumps in parallel, though, generally should be avoided as parallel operation can present some risks.

In those situations where parallel pump operation is desired, pressure on the suction and discharge sides of each pump should be equal. Accordingly, suction and discharge manifold piping should be symmetrical when two or more pumps are fed from one common suction intake or discharge into a common header