CO2 compressor support for biofuel plant projects

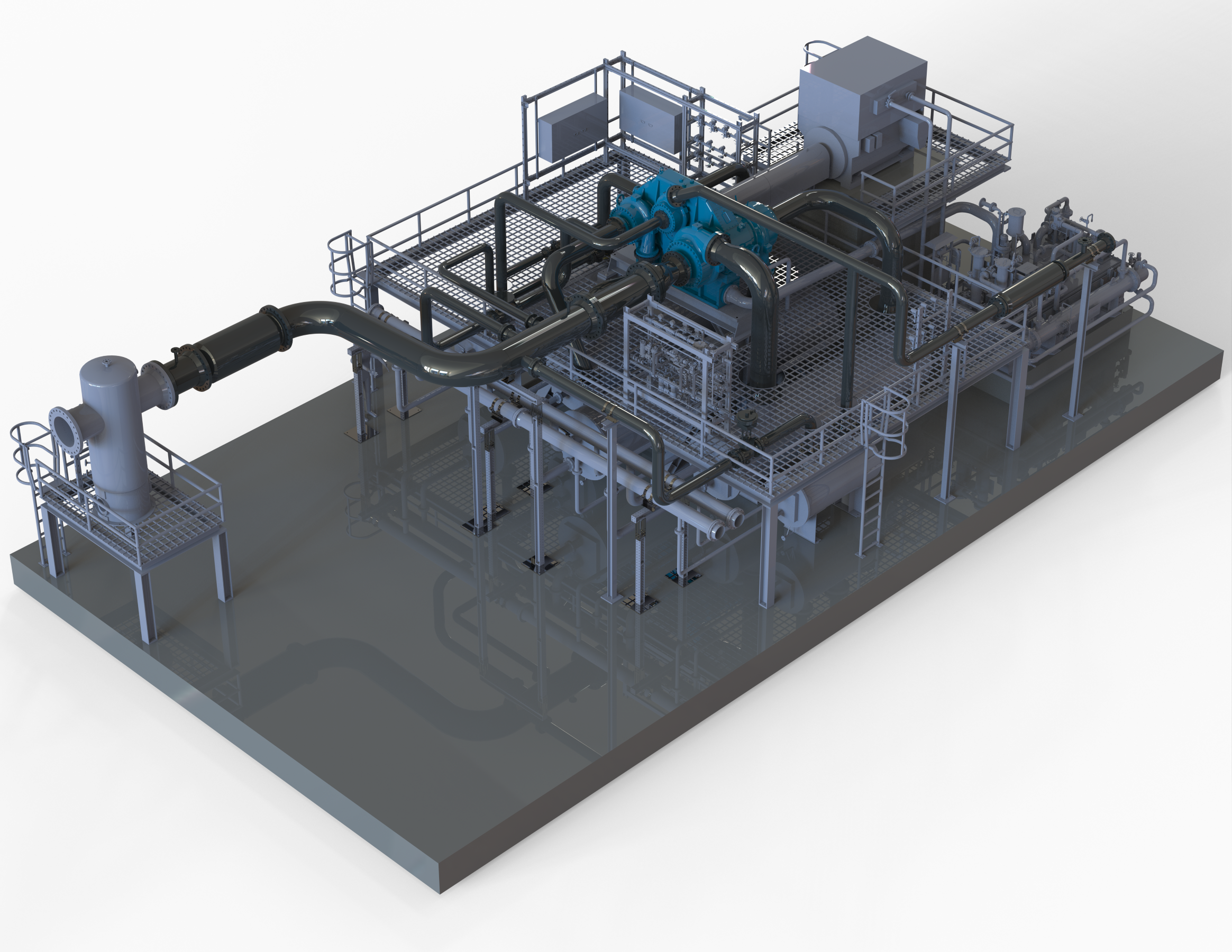

Atlas Copco 5-stage CO2compressor

Atlas Copco Gas and Process will be supplying CO2 compression equipment to one of Europe’s most ambitious renewable biofuels plant projects. The equipment will be used in an 820,000-tons-a-year biofuels facility, located at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (formerly known as the Pernis refinery). Once completed, the facility will be among Europe’s largest for the production of sustainable aviation fuel (SAF), renewable diesel, and renewable naptha made from biowaste.

In addition to fuel production, the project encompasses carbon capture and pipeline transport of CO2. This requires compression to a pressure of 42.5 bar by the Atlas Copco Gas and Process’ five-stage turbocompressor. The machine is designed to compress 43.5 t/h.

Expected to start production in 2024, the new facility will produce low-carbon fuels such as renewable diesel from waste in the form of used cooking oil, waste animal fat and other industrial and agricultural residual products using technology developed by Shell. As part of its strategy, Shell is currently transforming more than a dozen refineries into five energy and chemicals parks.

www.atlascopco.com