Doosan Škoda overhauls steam turbine at Sandvik 3 biomass incinerator in Sweden

“Parts wear out on practically every generating unit that is used daily and regularly exposed to high temperatures and pressure. With proper maintenance, the turbine can serve for many years, which is why we offer long post-warranty service with the option of overhauls and replacement of worn parts,” said Jan Houdek, Project Manager at Doosan Škoda Power.

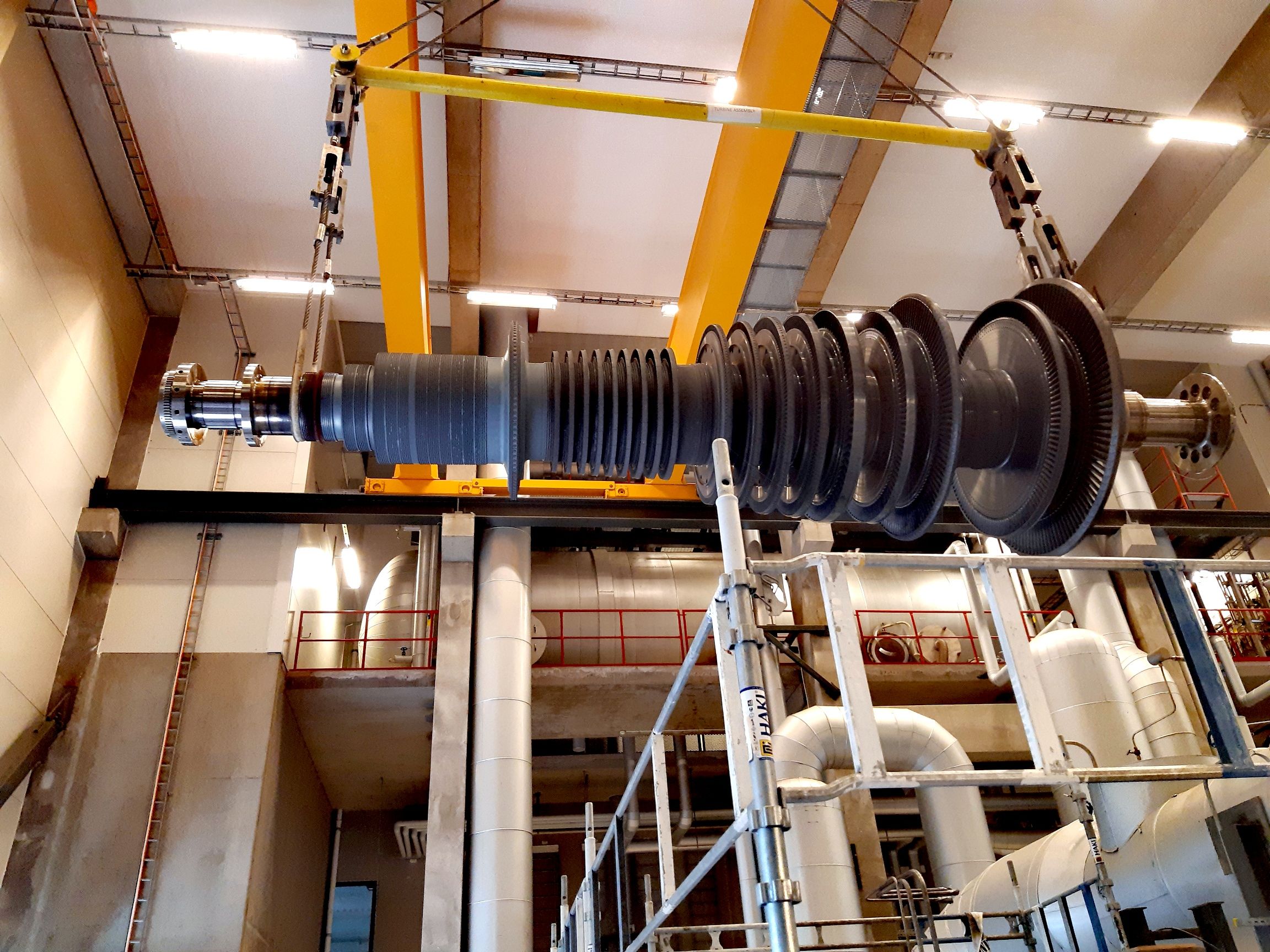

After the turbine is inspected and required spare parts are supplied, the next step is to disassemble the machinery, which is handled by teams of 5–8 which include designers, welders, electricians and fitters. The team is supervised by two chief head fitters, each of whom is in charge of a different part of the unit – one oversees the turbine, while the other is in charge of the steam control system. While technicians at Vaxjö were completing the dismantling, components that could not be repaired on-site, such as the rotor, the inner casing and the stator guide wheels, arrived in Pilsen. The opposite procedure awaited the team in Sweden during September, when the unit was re-assembled and subsequently commissioned, which was scheduled for October 18.

In cases where the turbine needs to be replaced by a newer model to increase efficiency or capacity, Doosan Škoda Power also offers retrofit and modernization services for steam turbines of its own or third-party production. Steam turbine servicing mainly means overhauls with replacement of worn components as well as long-term post-warranty service.

Doosan Škoda offers specialized 3D scanning services, reverse engineering, a remote monitoring system, as well as technical consultancy, repair and replacement of spare parts. These services can be provided directly at the power plant including on-site machining.

Fuel Flexibility in Heavy-Duty Gas Turbines: A Key Driver for Energy Transition

March 13th 2025From Hydrogen to HVO, Mr. Federico Bonzani, Chief Technology Officer of Ansaldo Energia, describes the fuel flexibility state-of-the-art solutions of the Company to meet the actual and future needs of power generation industry.