ELECTRIC DRIVES

HIGH-SPEED ELECTRIC MOTORS DRIVING GAS COMPRESSION

By Paul Blaiklock

Caption: High-speed synchronous motor used for driving a centrifugal compressor in a pipeline compressor station, one of forty-three such motor and drive pairs currently operating on a large Asian gas pipeline. The motors are Totally Enclosed Water to Air Cooled (TEWAC) type, using internal air circulation to cool the motor and an integral water-air heat exchanger to remove heat from the casing. The sleeve bearings are forced oil lubricated and cooled, and protected from shaft currents

Large centrifugal compressors are used on applications, such as gas pipelines, liquefied natural gas plants (LNG), petrochemical plants and refineries. In the past, these compressors have been driven primarily by gas turbines (GT) to provide the high power and high speed required. GT drives are popular for several reasons. A speed-increasing gearbox is not usually required, with resulting cost savings, and reduced need for lube oil systems and associated maintenance.

There is the convenience of using natural gas in areas where there is no electrical grid. Further, many users are familiar with the mechanical requirements of a GT. However, modern high-power systems consisting of electric motors and Variable Frequency Drives (VFD) represent an alternative approach. This technology is now capable of meeting the requirements for powering pipeline gas compressors (up to 30 MW and 40,000 HP). They have achieved high reliability (MTBF) and low repair time (MTTR).

They generate minimal air pollution and have low noise levels. Operating speeds range from 3,000 rpm to 12,000 rpm. Electric drivers have high efficiency and do not need a gearbox. Additionally, their soft motor starting capability minimizes the impact on the electric utility.

Recently, high-speed two-pole synchronous motors have been developed for operation at speeds above 3,600 rpm. This is made possible by powering the motor from a VFD at a power rating to match the application. Operating the motors at high speed requires motor power at a frequency above the usual 50 or 60 Hz. They have cylindrical rotors which can run at higher speeds than conventional salient pole synchronous motors.

For example, an 18 MW (24,000 HP) designed for variable speed operation at speeds from 5,200 to 5,460 rpm with no gearbox. The motor is a medium voltage, 6 kV design requiring little maintenance over its operating life. The VFD is used for starting, providing power during operation, and varying the motor and compressor speed to meet changing pipeline conditions. The rotor used has fans mounted on the shaft to provide internal air cooling, and an overhead water-cooled heat exchanger to remove heat. Shaft vibration levels are lower than American Petroleum Institute (API) limits. Motor efficiency is in the order of 98%.

For use in hazardous locations, such motors are certified Expxb or Expzc (Explosion protected, inner pressurized), using internal pressure to keep explosive gases out of the frame. Before power can be switched on, the enclosure is purged to remove any flammable gas that might have entered. Clean uncontaminated air from a nonhazardous area is fed to the motor to keep the internal pressure at least 0.5 mbar above ambient pressure. If pressure is lost, the system trips the motor. The exciter is an enclosed brushless type, which eliminates brush maintenance and allows non-stop operation.

Instead of the DC rotor field being fed from an external source through brushes, the DC current is generated directly on the rotor to magnetize the main rotating motor field, using a full-wave diode rectifier. This reduces maintenance and allows the exciter frame to match the degree of protection of the motor.

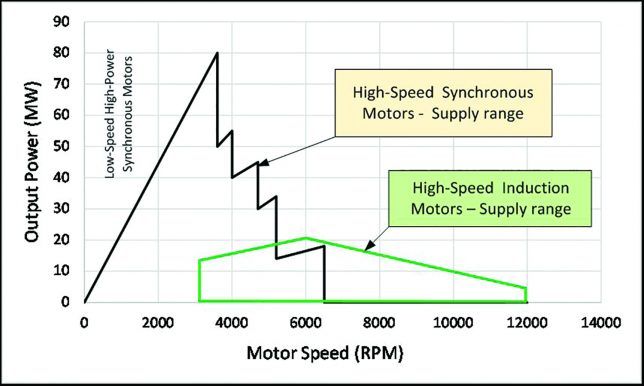

The exciter’s stator is fixed on its frame and both are assembled on the motor frame or motor base while its rotor rotates with the motor shaft. The exciter DC current can be varied by an external control to the AC input. With use of the VFD, synchronization is achieved at any speed. Both synchronous and induction motors are available for high-speed operation (Figure 1).

Figure 1: Supply range of high-speed motors

In general, synchronous motors can provide higher power and energy efficiency, but are more expensive. Induction motors provide speeds up to 12,000 rpm, but have a lower energy efficiency. VFD Motor starting and variable speed are provided by a VFD.

During startup, the VFD supplies reduced voltage and frequency to the motor, which permits proper magnetization without increasing current demand. This curtails starting stress on the rotor, allows for unlimited multiple starts, and reduces voltage stress on the power supply. The inverter design with pulse width modulated control and five-level output voltage results in an output waveform that minimizes torsional shaft vibrations.

For the 18 MW motor cited, the normal operating frequency range is 86.7 Hz to 91 Hz: speeds up to 5,460 rpm are available. Since the power sections of the drive are water cooled, the drive building air conditioning load is not large. Besides the transformer, other electrical equipment items include a low voltage distribution panel, flame-proof local control box, protection relay, and a programmable logic controller panel.

Author: Paul Blaiklock is Marketing Specialist at TMEIC. For more information, visit www.TMEIC.com