ELGi, IESS Tackle Natural Gas Flame-Off Ban with Compressed Air Solution: Air Source One

To capture and reinject natural gas into oil reservoirs, Air Source One uses rotary screw compressors, an integrated heater, and a ventilation system.

Industrial Equipment Sales & Services (IESS) designed and implemented the Air Source One package for the Bakken Formation, incorporating the ELGi EN Series rotary screw compressors, integrated heater, and ventilation system in a 6 ft x 12 ft enclosure. The package addresses the U.S. government’s 2024 ban on flame-off applications—the practice of burning off excess natural gas released during extraction. To satisfy the new regulation, companies must upgrade compressed air systems to capture and utilize excess gas rather than burning it.

"With the new regulations, our Air Source One system with ELGi air compressors becomes critical for companies to continue to operate efficiently, while following environmental standards," said Randy Schlossin, Sales Representative at IESS.

Air Source One

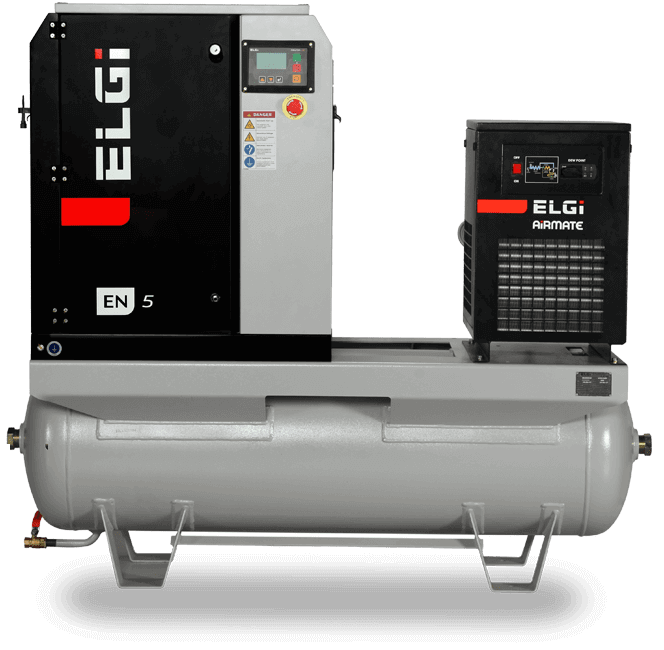

ELGi EN compressors are compact, allowing a regenerative air dryer to be mounted on the compressor tank, then compresses and reinjects spare natural gas into the oil reservoir. Its small footprint and durability enable placement near oil well sites. IESS selected these compressors due to their compactness, serviceability, and dryer-mounting capability, ranging in power from 4 – 20 hp with a capacity of up to 150 psi. Due to installation at remote locations that prevent speedy maintenance, a duplex compressor can be used for redundancy.

“With the field-proven quality of ELGi EN Series air compressors, we can provide end-users with the most economical and reliable dry air from the most remote locations,” Schlossin said. "This capability extends to supporting flame-off operations and beyond, ensuring continuous, dependable service no matter the environmental conditions or operational demands."

EN Series screw compressor; image credit: ELGi

According to IESS, the EN Series compressors are easy to maintain for oil field applications:

- Side panels can be quickly and easily removed

- Preventative maintenance parts can be replaced with minimal work

- Belt drives feature a 10,000-hour life expectancy

Bakken Background & Partnership

The Bakken Formation is located in North Dakota and contains large oil and natural gas deposits—over 17,000 producing oil wells. Compressed air is vital to companies operating in the Bakken region, as it powers natural gas compressors, actuate instruments, and the air supply for oil well applications.

In terms of the partnership, IESS and ELGi have a long-term relationship based on reliability, with the teams cooperating to deliver quick response times and minimal downtimes for customers. IESS supports the installation of new compressed air systems, provides field service, and maintains an inventory of parts, while ELGi’s technical support team troubleshoots, maintains, and helps assure the optimal performance of IESS’s compressors.

“Our whole foundation is built on service and keeping everyone up and running,” said Schlossin. “The ELGi support team brought in years of expertise to respond to our needs very nicely and steer us in the right direction. Together, we are positioned to respond to the customer’s needs.”

Flaring Emissions

One of the big ways oil and gas companies such as bp have reduced their methane emissions is by eliminating flaring. bp aims for zero routine flaring by 2025 at its U.S. onshore operations and globally by 2030 and Saipem, an Italian multinational oilfield services company, also pledged zero methane leakage by 2030. At the Baker Hughes Annual Meeting, Alessandro Puliti, the CEO and General Manager, talked about the company’s zero-flaring technology for power plants and other areas of the infrastructure to detect fugitive methane emissions.

“All new design and engineering for our new plants is done to ensure zero flaring and zero fugitive emissions while lowering the physical and environmental footprint,” he said.