FS-Elliott Launches Compressor Monitoring Solution: R3000 Control Panel

The R3000 control panel is equipped with remote monitoring capabilities, offering a comprehensive data dashboard and customized reports to ensure reliable compressor operation.

FS-Elliott announced the launch of its new programmable logic controller for centrifugal compressor applications—the R3000 control panel. The configurable design enables reliability, energy efficiency, and advanced customization via advanced compressor diagnostics with onboard historical data tracking. Leveraging data-logging capability, users can quickly obtain factory-direct engineering assistance.

"We’re excited to introduce the R3000 control panel, manufactured in America and the latest addition to our Regulus series," said Justin Johnson, Product Manager, Aftermarket & Controls at FS-Elliott. "The R3000 not only sets a standard in efficiency and reliability but also supports our customers' ESG efforts. This panel is designed to enhance performance, streamline maintenance, and contribute to sustainable operations, offering a tool for achieving operational excellence while advancing environmental and social goals."

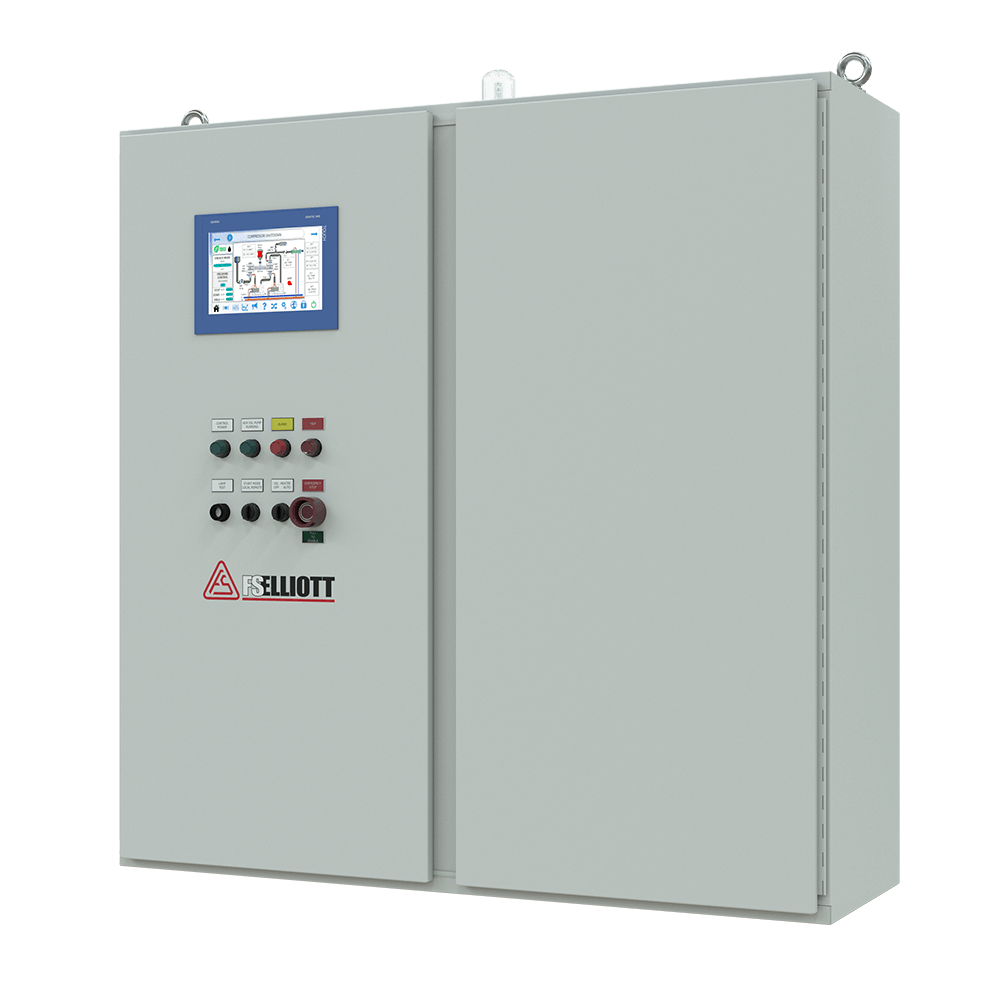

R3000 control panel; Image Credits: FS-Elliott

The R3000 uses FS-Elliott’s Energy Advisor and Maintenance Notification system to ensure compressor operation at optimal efficiency and reliability.

Energy Advisor: Continuously monitors operational efficiency and enables improvement via automated, actionable suggestions.

Maintenance Notification: Tracks the usage of maintenance parts and alerts users when predictive maintenance (PdM) is required. As a byproduct, PdM alerts reduce energy consumption and CO2 emissions.

FS-Elliott also equipped the R3000 control panel with remote monitoring capabilities: an optional FS-Connect system offers a comprehensive data dashboard and customized reports to further enhance efficient, reliable operation. FS-Elliott Channel Partners will receive notifications when service is needed, which minimizes unnecessary or unscheduled downtime.

Compressor Control with FS-Elliott

At Turbomachinery & Pump Symposia (TPS) 2023, Turbomachinery International spoke with Dominic Sarachine, Product Manager at FS-Elliott, about air compressors and centrifugal compressor control systems. Sarachine said compressor control systems would evolve toward smart machine concepts, as exemplified by the company’s latest R3000 control panel.

“Centrifugal compressor control systems continue to evolve toward smart machine concepts that ensure efficient and reliable operation at all times,” said Sarachine. “Key developments that support smart machine operations include the continued development of energy monitoring systems, predictive maintenance systems, and data analytics through remote monitoring. Coupling these systems together not only helps to reduce a user's carbon footprint through CO2 emission reductions but can allow for OEM troubleshooting without the lost time and cost of a site visit.”

When addressing the focus of TPS 2023, Sarachine linked compressor controls to efficiency and reliability: “This year's show focused heavily on reliability and efficiency, both in the lectures and by exhibitors. Through advancements in instrumentation and controls, operators can increase the reliability of their machines through more predictive indicators. These indicators allow them to be proactive in performing maintenance on equipment and eliminate unplanned downtime. Similarly, efficiency has become even more important as operators look to reduce energy costs and carbon emissions as a result of equipment operation.”