Fuel Flow Meters

ACCURATE MEASUREMENT OF NATURAL GAS FLOW IS MORE IMPORTANT THAN EVER IN AN AGE OF LOW-QUALITY NATURAL GAS

There is no doubt that gas-fired generation has gained serious ground over the past couple of decades. As coal and nuclear decline, natural gas and renewables have picked up the slack. But while the demand for natural gas has risen, many areas have seen a decline in the quality of the gas supply.

In North America, for example, the shale gas boom has resulted in power plants receiving gas which includes various impurities. In other parts of the world, an increasing reliance on gas from unconventional sources means greater concentrations of H2S and other potentially hazardous components.

These newer sources of natural gas typically contain an overabundance of heavier hydrocarbons. One simple cycle plant in the Marcellus shale field in the U.S., for example, was receiving gas that contained more than 20% ethane and oil sludge. As a result, the gas supply fell outside the quality specified for operation of its fuel nozzles. If the plant burned that fuel, the nozzles and the combustion system could have been damaged.

Another problem is that the makeup of gas can vary over time. Shifts in shale gas dew point mean that gas that met quality standards in the morning may no longer qualify in the afternoon.

This comes about as changes in the dew point impact the temperature at which the gas stream undergoes a phase transition to liquid at a given pressure. It is vital, therefore, that power plants closely monitor their gas before allowing it to enter their turbines.

Preventing damage

During hot weather the temperature inside a pipeline can rise dramatically. This affects the hydrocarbon dew point. Heavier hydrocarbon elements that are in a gaseous state during the day may condense at night to form more liquids inside the pipeline. Such liquids can cause damage to combustors and other turbomachinery components.

Fuel quality is also an issue. There are more gas supplies available than ever before, each with a different gas makeup. Gas compliant to machinery specifications can suddenly become hazardous due to its point of origin shifting. These days more than ever, plant managers have to closely monitor gas quality rather than relying on the measurement data of others.

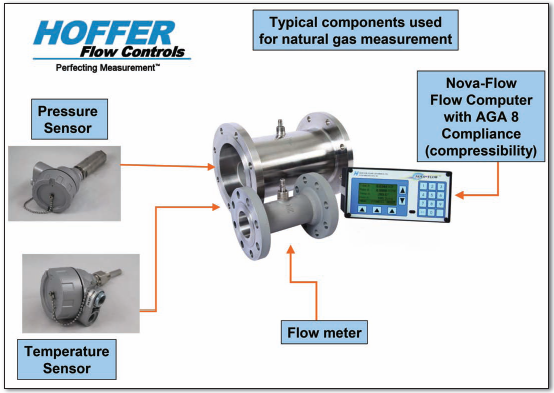

Monitoring of natural gas is accomplished via a fuel flow meter that is installed before the gas is fed into the combustor. There are several types of flow meter options available. For gas-fired turbines, the main choices are mass Coriolis, multipath ultrasonic and turbine flow meters (Figure 1).

Figure 1: Hoffer Flow turbine flow meters are used to ensure gas quality and flow accuracy[/caption]

Mass Coriolis instruments make use of the Coriolis effect. A vibration is induced in the flow tube, and sensors monitor changes in frequency, phase shift and amplitude which help determine the mass flow rate.

These meters are accurate, meet many industry standards and are widely used. However, they often require a large independent foundation as well as regular calibration to maintain accuracy levels.

Multipath ultrasonic devices are also commonly employed in fuel flow measurement. They use ultrasonic pulses to calculate the amount of gas passing through the meter. As they do not depend on kinetic energy, low rates of flow can be measured. These meters provide virtually zero pressure drop but come with a higher price tag.

As they have no moving parts, maintenance costs are low. Turbine flow meters were first developed for fuel measurement on aircraft, and are used today on the latest stealth jets. These devices measure the velocity of a moving fluid (Figure 2).

Figure 2: Differential control regulator for both pressure reducing and backpressure service[/caption]

Turbine flow meters offer accuracy (0.25% of reading or better) that can be maintained over a turndown range of 100:1 or more. Calibration is easiest on this type of meter.

For gas turbines, turbine flow meters are generally the best option. Those specifying them should look for those characteristics which matter most — accuracy, performance, approvals, repeatability, pressure drop, price, materials, compliance, turndown range and calibration.

Relevant approvals

Particularly for small gas turbines, approvals play a vital role. As gas turbines are shipped all over the world, manufacturers that provide the widest range of approvals are a wise choice as requirements vary widely from continent to continent and country to country. Relevant approvals include ATEX, PED 97/23/EC, NACE, Hand Book 44 USA, OIML, R-81-World, CSACanada, NIST-USA, CE Standard – Europe, Dantest – Denmark, NORSOK, ISO-IEC 17025, ASME B31.3, AGA Report 9, ISO CD17089 and ISO 9001.

For larger gas turbines, accuracy and high performance are the most important elements of the selection process. On the performance front, response times should be in the tens of milliseconds range for best results.

The industry’s general accuracy standard is 1.5% of reading. However some power plants require measurement accuracy down to 0.25% to assist in their emissions monitoring efforts.

Repeatability deals with how well a measuring device is able to display the same value of a measured variable under identical conditions. Look for a repeatability factor of 0.1% or better for best results with large gas turbines.

CFR compliance is another area to consider. The U.S. Clean Air Act has requirements for fuel flow meters as covered under 40 CFR 75. This gives an elaborate description of the calibration and accuracy standards for these meters. Vendors have to provide meter calibrations that demonstrate they comply with this standard.

When it comes to calibration, the process should be simple, straightforward and should not have to be repeated endlessly. Users want an accurate fuel meter that provides reliable readings without continual need for verification.

Some plants continue to use orifice and differential pressure meters in gas fuel flow measurement. However, these instruments have a limited turndown range that can be an issue in some natural gas applications. Stick to meters with an adequate turndown range.

Price, too, plays a part. For gas turbine fuel flow, there is no need to specify the most expensive type of meter as that may not provide the best return on investment. But it is also wise to avoid low-priced meters that may not provide the performance required for gas-fired plants.

Some manufacturers make components from plastic or aluminum, but these are not robust enough for the heavy duty nature of gas-fired facilities. Similarly, corners can be cut with rotors.

Dynamic response

Cast rotors inside turbine fuel meters, for example, are heavy and this translates into slower dynamic response to changes in flow rate. Rotors that are precision machined from bar stock are lighter and provide faster response. Opt for models with relatively low maintenance needs.

Pressure drop can vary from one turbine flow meter to another and this has to be balanced against other factors. Curved blades, for example, are known to extract the greatest amount of energy from a fluid stream which makes them attractive for power plant applications.

However, curved blades also produce a higher pressure drop. Flat blades, on the other hand, often provide the best mix of performance and pressure drop.

Correct flow measurement of natural gas is vital in determining a plant’s thermal efficiency in converting fuel BTUs to kWhs, and balancing output with the correct degree of control over plant stack emissions. Contracts between the turbine OEM and the utility, for example, often guarantee certain levels of thermal efficiency.

For a specific amount of fuel, a definite amount of electricity output is expected. If the conversion from BTUs to kWhs is not what it should be, contractual penalties can come into play. Utility billing meters provided by gas pipeline companies are far less accurate than turbine fuel meters for ensuring gas quality and flow accuracy.

Written by: