News

Article

GE Vernova to Fulfill Amprion’s Bulk Order for Power Transformers

Author(s):

Amprion has awarded the supply contract to GE Vernova for the production and delivery of 12 400 kV transformers.

Amprion GmbH, in an effort to kickstart Germany’s energy transition and replace older power assets, has awarded GE Vernova’s Grid Solutions business with a contract for 12 400 kV power transformers. These transformers will be built at GE Vernova’s grid facility in Monchengladbach, Germany.

“As utilities transition to renewable energy sources, electrical transmission grid operators continue to face increasing demand and complexity. Today’s transmission systems are expected to carry bulk power in ways they never originally were designed to accommodate,” said Philippe Piron, President and CEO of GE Vernova’s Grid Solutions business. “We are proud to support Amprion, a long-time valued GE Vernova customer, to reinforce their 400 kV electrical grid. Our power transformers will help them increase capacity and maintain stability on their network.”

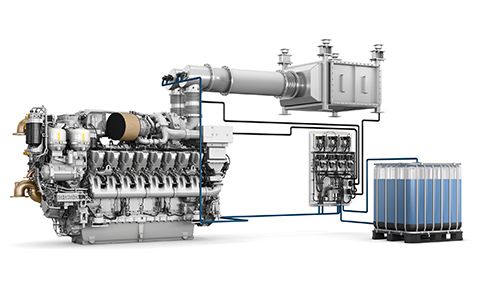

GE's 400 kV power transformer; Image Credits: GE Vernova

Equivalent to more than 5,000 MVA, this order of GE power transformers is capable of supplying electricity to the 29 million people living within Amprion’s grid. The high voltage, 11,000 km-long grid stretches from Lower Saxony to the Alps, covering an area that’s responsible for one-third of Germany’s economic output. GE Vernova plans on delivering the power transformers over the course of two years, from 2025-2027.

GE Vernova’s fleet of power transformers will be replacing modules installed in the 1970s, allowing Amprion to take advantage of updated grid technology and the integration of renewables. The advanced transformers will be installed at nine substations along Amprion’s grid, joining a fleet of previously purchased GE grid products such as switchgears, gas-insulated switchgears, mechanically switched capacitors, and additional transformers. GE Vernova has been fulfilling orders from Amprion since 2003.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.