Hyliion, BayoTech Advance Hydrogen Power with Hubs, KARNO Generator

The duo signed a partnership agreement to leverage their hydrogen power solutions for new customers, including Hyliion’s KARNO generator and BayoTech’s hydrogen hubs.

Hyliion Holdings and BayoTech are partnering to leverage the power solutions of both companies for current and future customer bases.

“By pairing BayoTech's hydrogen solutions with Hyliion's KARNO generator technology, we will empower customers with a cleaner, more efficient alternative to traditional diesel gensets,” said Mauricio Vargas, President and CEO of BayoTech. “Our commitment to revolutionizing the hydrogen supply chain through local production hubs aligns perfectly with Hyliion's mission to deliver net-zero carbon electricity. Together, we're not just challenging the status quo – we're reshaping it for a more sustainable future."

The KARNO generator can operate on multiple fuel types, including hydrogen, and is designed for applications such as prime power, renewables matching, and energy arbitrage. It is undergoing the advanced stages of development and is scheduled for field deployment in the latter half of 2024 for early adopter customers. The BayoGaaS hydrogen production hubs have high-pressure transport trailers and storage hubs to ensure a reliable hydrogen supply chain for its customers. The partnership will support each company’s product offerings across both customer bases.

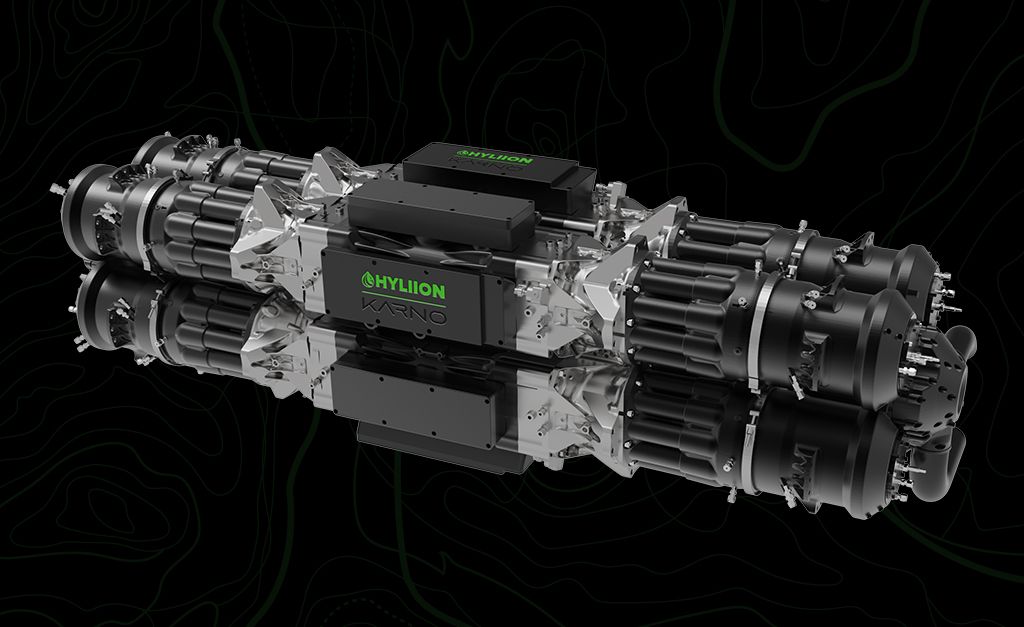

KARNO generator; Image Credits: Hyliion

"Hydrogen holds great potential as a zero-carbon energy source, yet its widespread adoption faces infrastructural challenges,” said Thomas Healy, Founder and CEO of Hyliion. “Companies like BayoTech solve this problem, allowing customers to use hydrogen in their operations today. Our collaboration will provide a comprehensive solution in the future tailored to customers' needs, accelerating a faster adoption of new power generation technologies."

A panel of industry experts and OEMs discussed the various obstacles preventing the large-scale implementation of hydrogen in the September/October issue of Turbomachinery International, including the costs of manufacturing hydrogen, transporting it to a power station, and providing large-scale storage at the site.

Klaus Brun outlines some of these obstacles, “The primary obstacle to the large-scale implementation of hydrogen as an energy carrier is the cost of hydrogen production, transport, and storage. It is difficult to utilize or convert the existing hydro-carbon transport infrastructure to hydrogen transport because of the challenging physical properties of hydrogen. As previously noted, hydrogen is not an easy gas to handle. Thus, to convert our industrial and domestic usage from fossil fuels to hydrogen requires an entirely new infrastructure, which could cost trillions of dollars. This is something that will take time, money, and commitment to implement.”