Quantitative assessment of compressor performance

Today machinery maintenance works require improvements in the evaluation of the machine conditions. In fact, often one critical task for the plant management consists in taking the decision to stop the machine or run until the next planned plant outage. These evaluations and decisions are in many cases still based on an expert’s indications, which are often experiential and subjective.

Software can help assess centrifugal compressors' health conditions through quantitative comparison of field operative parameters to ones predicted from machine computer model.

While intended not to replace human experts but rather to support them better, the method has been applied jointly with mechanical best practices, vibrational machinery analysis, accurate mechanical inspections and high quality repair processes and procedures.

This approach, aimed to exceed the actual best practices, can support plant management in the maintenance decision-making steps and maximization of plant ROI.

Method description

Quantitative assessment of compressor performance and health status needs the comparison of measured performance to design ones adjusted at actual operative conditions. Starting from OEM design or test performances maps, software allowed to predict compressor expected performances in the actual inlet conditions (actual suction temperature and pressure and gas mix composition).The software calculates, at the actual running speed, the following expected curves, valid for actual inlet conditions:

Discharge pressure vs suction flow

Discharge temperature vs suction flow

Compressor efficiency vs suction flow

Polytropic Head vs suction flow

Availability of above maps allows to calculate, at the actual flow, the values of expected pressure, temperature, Head and efficiency and then compare to the measured ones. A comparison of these values can detect deviations and provide quantitative information about the actual compressor health status and possible operational problems.

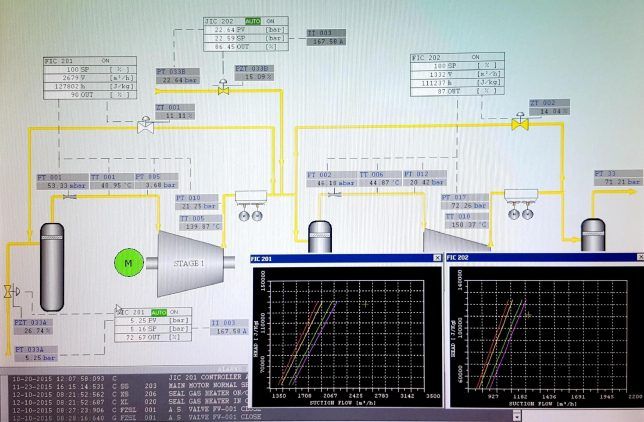

The following picture shows a typical process screen

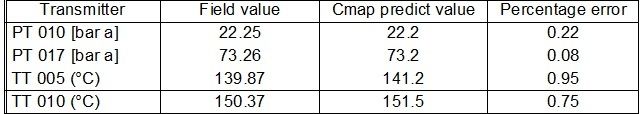

With reference to above process screen, the following table compares the pressures and temperatures from PT/TT transducers to the value predicted by software:

In the previous tables it can be noted how the maximum error calculated is less than 1 %.The same comparison has been executed for Head and Polytropic efficiency.

Measured errors have been considered tolerable for the purpose of the evaluation of compressor field performance.The analysis developed obtained an evaluation of the efficiency deviation (difference between the actual compressor efficiency and the expected efficiency in the actual operative conditions). Time trends of calculation results provided a useful analytical basis for compressor maintenance decisions.

The method has been profitably used to predict compressor performances and support planning of machinery maintenance activities.

Conclusion

Numerical prediction of compressor performance allows a quantitative evaluation of compressor health status. The applied methods allowed also to:

- predict the performances of a centrifugal compressor under varying thermodynamic conditions of the inlet gas. The prediction of compressor performances is accurate even at high pressures, where the ideal gas theory and simplified formulas approach is commonly used, introduce considerable errors.

- analyze the performance of the compressor during operation and compare them with those expected provided by the OEM.

- implement advanced protection from surge, overcoming limits of the current technology

- having useful indications on the health of the compressor (diagnostics) based on the capability to analyze the performances and efficiency of the machine in a simple and immediate way

- support decisions and planning of maintenance and activities for optimization of plant productivity