News

Article

MAN Energy Installs Propulsion Packages on Royal Fleet Auxiliary Vessels

Author(s):

The company will provide 12 V32/44CR propulsion engines, six L32/44CR gensets, selective catalytic reduction for each engine, and three Alpha CP propellers.

In 2023, the U.K. Ministry of Defense awarded a contract to Team Resolute—Navantia UK, Harland & Wolff, and BMT—to deliver three Fleet Solid Support (FSS) ships to the Royal Fleet Auxiliary. MAN Energy Solutions will deliver a naval package that includes requirements for FSS ships, such as shock resistance, cyber security, NBC, integrated logistics support, efficiency, low-emissions, and reliability. Through a later retrofit of 32/44CR engines to green methanol, CO2 emissions could be further reduced.

MAN Energy will supply 12 V32/44CR propulsion engines, six L32/44CR generator sets, selective catalytic reduction for each engine, three twin-screw Alpha CP propellers, and plant auxiliaries. The primary task of FSS ships will be the replenishment of dry stores for Royal Navy vessels. Mission capabilities include logistics support, operation support, anti-piracy, and anti-terrorism.

“Navantia is an important partner for navies around the world and we are proud to be chosen to participate in this FSS program for the Royal Fleet Auxiliary,” said Andreas Junginger, Head of Sales, Navy at MAN Energy Solutions. “This high-end naval application marks another milestone for our Navy business and we are looking forward to further developing our cooperation.”

FSS vessel concept; Image Credits: MAN Energy Solutions

Navantia UK is the prime contractor, BMT Group will provide expertise in advanced naval design, and Harland & Wolff, along with Navantia, will build the vessels. Most hull blocks will be constructed in Harland & Wolff shipyards, with integration, test, trials, and delivery occurring at the Belfast facility.

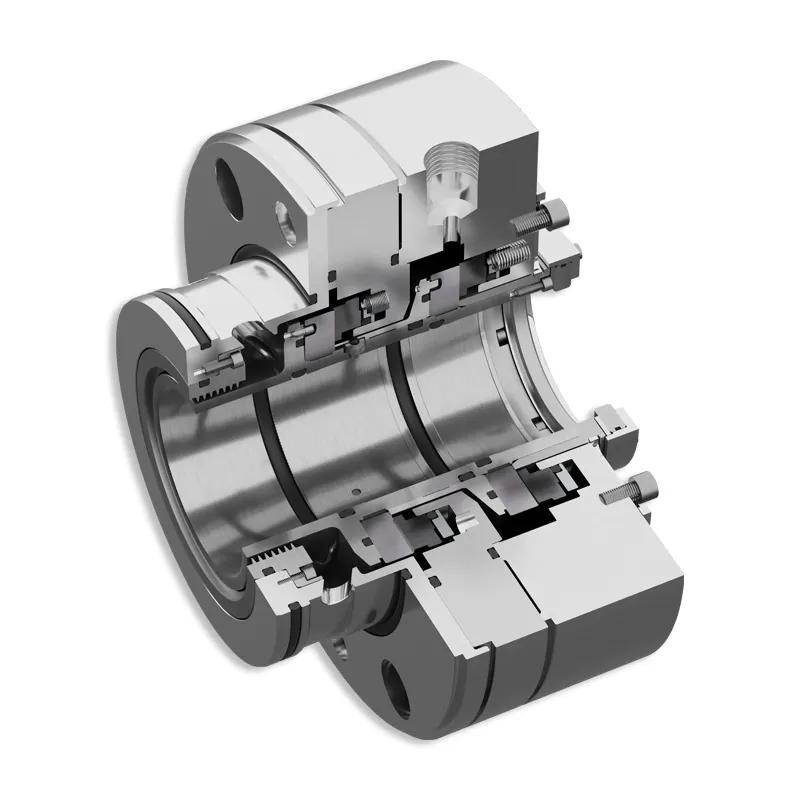

MAN Energy Naval News

Last week, MAN Energy Solutions released a new common-rail injection system for its medium-speed, four-stroke engine portfolio: the CR 2.2 common-rail fuel-injection system to replace its CR 1.6 predecessor. The CR 2.2 system allows precise and flexible control of injection pressure, timing, and duration throughout complete operating ranges. Engine performance, emissions, and fuel consumption can be optimized with precise control.

The CR 2.2 generation contains an optimized and uniform high-pressure pump, a newly developed injector, and the CR 1.6 valve group, with initial introduction on the MAN 49/60DF engine. According to MAN Energy, it can have up to 38% increased rail-pressure across all applications and over 33% increased target time-between-overhaul intervals for most components. The CR 2.2 system features 35% fewer high-pressure connections, enabling reduced leakage risk and greater service compatibility.

In late August, New Times Shipbuilding Co. ordered 12 8G95ME-GI (gas injection) main engines from MAN Energy Solutions. These engines will be installed on 12 under-construction container vessels, rated at 18,000 teu, for Eastern Pacific Shipping (EPS) Co. in Singapore.

MAN Energy’s ME-GI engine is a two-stroke propulsion model used in RoRo vessels, pure car and truck carriers, container vessels, bulk carriers, tankers, and LNG carriers. The engine offers ship owners, charterers, and operators with environmentally friendly, high efficiency operation, without the methane-slip emissions of traditional engines.

The diesel principle provides the ME-GI engine with 100% reliable operation during gas load changes with normal additions of pilot-oil amounts. It can switch between gas and diesel operation. The company also developed an ME-LGI (liquid gas injection) dual-fuel engine that enables the use of sustainable fuels such as green methanol.

Newsletter

Power your knowledge with the latest in turbine technology, engineering advances, and energy solutions—subscribe to Turbomachinery International today.