NEW INNOVATION CENTER FOR SIEMENS

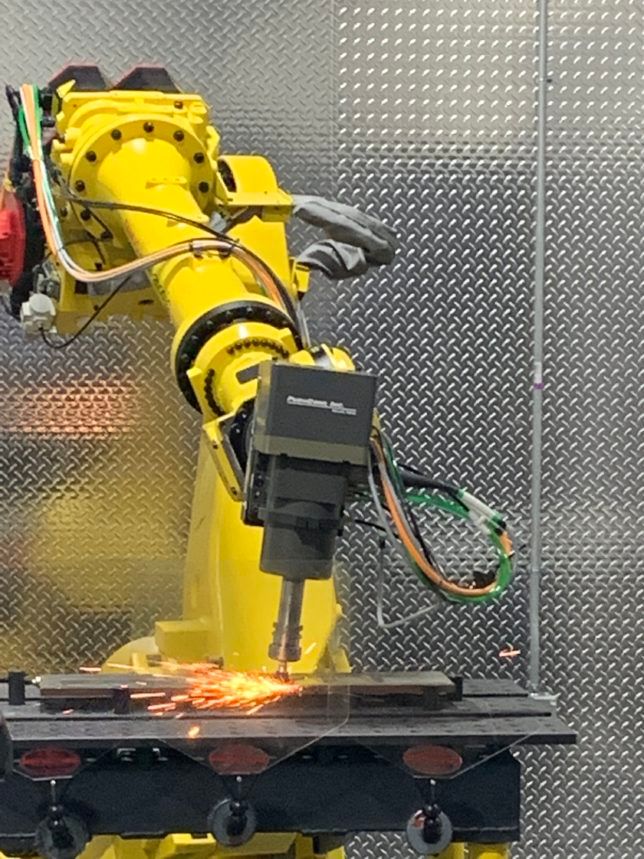

Caption: This Fanuc CNC machine at the Siemens Innovation Center is grinding a part

3D printing, also known as additive manufacturing (AM) is front and center in cutting edge research and development (R&D). Siemens is betting heavily on the technology to drive the next phase of turbomachinery innovation with the opening of a new Innovation Center in Orlando, Florida.

This center combines multiple disciplines, such as design, manufacturing, robotics, rapid prototyping, scanning and digital tools under one roof. As well as supporting the customers of Siemens Gas & Power, it also provides parts and new developments for aerospace and Siemens partners.

Collaboration is a key facet of the facility. Instead of the usual workforce made up of mechanical engineers and designers, it also includes electrical engineers and specialists in manufacturing, turbomachinery services, software development, robotics, augmented reality (AR), AM, non-destructive evaluation (NDE), and simulation.

"Our new innovation center is equipped with the latest digital technologies,” said Mark Kamphaus, head of Technology & Innovation for Siemens Service Power Generation. “This enables us to rapidly develop repairs, new components and digital solutions.”

Siemens intends to use the center to enhance the performance of its products and systems. With the market being more competitive than ever, cost reduction is another driver in technology development at the center. With the opening of this center, Siemens now has a network of four AM-based sites.

As well as Orlando, there is Materials Solutions in UK, a company Siemens bought a couple of years ago, but maintains as an independent entity. Materials Solutions was purchased to save time in 3D printing development. This strategic purchase provided Siemens with immediate know-how to apply AM to gas turbines (GTs) and steam turbines (STs).

The goal is to look beyond printing of parts to jointly develop new materials and new 3D printers. These services will be offered to the aerospace and energy sectors. There are also AM centers in Sweden and Germany. Kamphaus does not envisage the Orlando site being used for production. Instead, its focus will be on R&D, prototyping and proving out concepts prior to implementing into production.

There are two 3D printers already on location and another one on the way to the Orlando center. A tour of the facility showcased the 3D printers and a host of other high-tech gear. The latest robots are used to mill, grind, pick and place components. Siemens is using the site to perfect robotic processes before they are implemented on the shop floor.

“We want to automate a great many actions that are currently done manually,” said Kamphaus. “We can pilot them here, refine them and scale them to our manufacturing operations.”

He sees this as one of many areas where turbomachinery costs can be reduced to make the technology more attractive in the marketplace. Siemens has also invested heavily in NDE equipment and processes. NDE is useful in areas such as quality assurance, failure analysis and reverse engineering. The NDE team at the Innovation Center seeks to introduce a greater level of automation to NDE, qualify suppliers and optimize techniques. The center’s capabilities include radiographic, ultrasonic, magnetic particle, eddy current, infrared and penetrant inspection.

The next part of the tour was the Collaborative Engineering Hub. Its purpose is to bring together many different kinds of engineers with scientists (in physics, computers and other disciplines) and experts in sensors, project management, logistics, production, aerospace, software, and computer- aided machining.

About 35 engineers working there are seated in close proximity to these experts to encourage tighter collaboration. A full machine shop at the site provides faster output and more streamlined workflows than could be obtained if Siemens had to send specialized components to outside partners.

Kamphaus explained how long it might take to design something, including iterations back and forth between engineering and outside partners for many weeks until the part was correctly produced. This consumes too much valuable prototyping time.

“We often make a plastic model for a component in a 3D printer and assemble it to see how it works,” said Kamphaus.

The machine shop incorporates rapid prototyping, manufacturing, computer numerical control (CNC) milling, CNC turning, electrical discharge machining and waterjet cutting. Additionally, 5-axis and 2-axis machines are available to work in metal or plastic.

During the tour, a technician demonstrated an ongoing project to develop complex die cores in aluminum. Siemens wants to get it right before it goes into a production run by proving out all the tool paths. “Our facility can now support some of our most urgent needs and prove out things so there are no delays,” said Kamphaus.