Rolls-Royce’s Aero-Hydrogen Research Project Makes Headway

Recent tests support the combustion element of Rolls-Royce’s hydrogen program after running an aircraft combustor on 100% hydrogen.

Rolls-Royce and easyJet—partners in developing hydrogen combustion engine technology for aircrafts— are working with Loughborough University in the United Kingdom and the German Aerospace Center, Deutsches Zentrum für Luft-und Raumfahrt (DLR), to test a full annular combustor of a Pearl 700 engine running on 100% hydrogen. The team has shown that 100% hydrogen fuel can be combusted at conditions representing maximum take-off thrust.

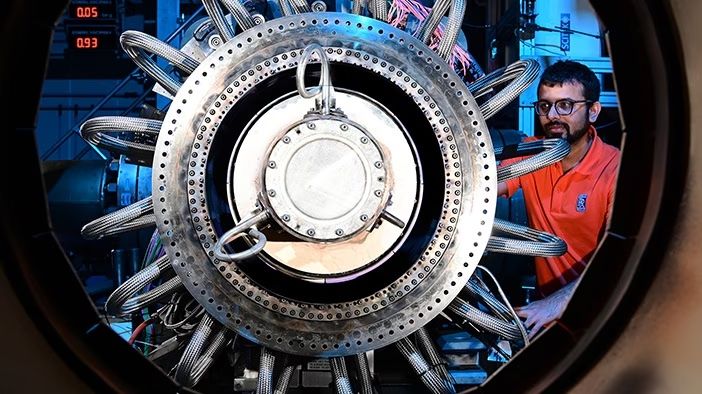

Hydrogen testing at DLR, Cologne. Credit: Rolls-Royce

“This is an incredible achievement in a short space of time,” said Grazia Vittadini, Chief Technology Rolls-Royce. “Controlling the combustion process is one of the key technology challenges the industry faces in making hydrogen a real aviation fuel of the future. We have achieved that, and it makes us eager to keep moving forward.”

Pivotal of this achievement was the design of fuel spray nozzles that control the combustion process. This involved overcoming engineering challenges, as hydrogen burns hotter and faster than kerosene. The new nozzles control the flame position using a new system that progressively mixes air with hydrogen to manage the fuel’s reactivity. The nozzles were initially tested at intermediate pressure before the final full-pressure combustor tests.

“We believe hydrogen is the future of short-haul aviation and the success of this test and progress being made demonstrates that this is becoming ever closer,” said Johan Lundgren, CEO of easyJet. “We remain optimistic that it will play a critical role in helping us achieve the ambitious goals we set out in our net zero roadmap.”

The technologies tested will be incorporated into the learning from the Boscombe Down tests as Rolls-Royce and easyJet prepare for a full gas hydrogen ground test on a Pearl engine followed by a full ground test on a Pearl engine using liquid hydrogen.

“This is an outstanding success story, and we are more than happy to have contributed our hydrogen testing capabilities,” said Markus Fischer, Divisional Board Member Aeronautics of DLR. “It was very exciting supporting this technology journey and seeing the burner technology mature in various rigs at our Institute of Propulsion Technology. This underlines again DLR’s capabilities in complex applied research and the achievement, at such a high pace, was supported by our experience in real-scale testing of ground-based gas turbines.”