Siemens Energy to supply FPSO vessel in South America

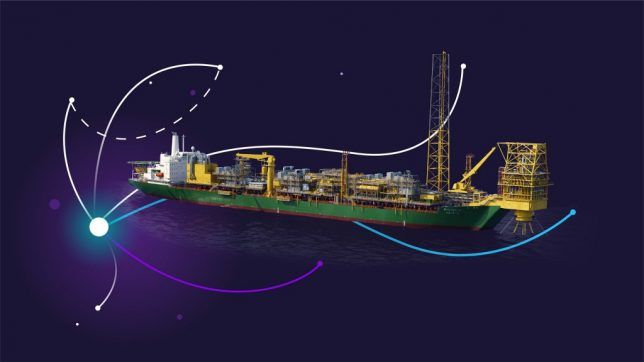

Siemens Energy will supply eight complete topside modules for a floating production, storage, and offloading (FPSO) vessel in an offshore oil field in South America. The FPSO is scheduled for start-up in 2024.

MISC Berhad, which procured Siemens Energy in an engineering procurement construction (EPC) contract, is building the FPSO to expand its fleet of 14 floating production systems. The FPSO is expected to have a processing capacity of 180,000 barrels of oil and 12 million cubic meters of gas per day.

Siemens Energy will supply EPC work for all eight modules and several key components: two electric, low-pressure centrifugal compressors; two electric, CO2 compressors; three main injection compressors driven by Siemens Energy SGT-A35-GT62X gas turbines; four Siemens Energy SGT-A35-GT30 gas turbines for power generation; an E-house; plus all electricals including an electrical control and management system (ECMS).

The topside modules will be designed and manufactured across Asia, with main engineering and execution activities done through Singapore. Packaging for all the rotating equipment packages will occur at Siemens Energy’s Santa Barbara d’Oeste facility in Brazil. The facility is also fully equipped to provide support and service to the FPSO’s modules once it is deployed.

The ECMS is designed to provide monitoring and supervision for the power generation and distribution network for load management of the FPSO facility, including topside and marine. MISC Berhad and the FPSO operator can use the ECMS to monitor FPSO power, generate reports, and plan for future sustainability.

Fuel Flexibility in Heavy-Duty Gas Turbines: A Key Driver for Energy Transition

March 13th 2025From Hydrogen to HVO, Mr. Federico Bonzani, Chief Technology Officer of Ansaldo Energia, describes the fuel flexibility state-of-the-art solutions of the Company to meet the actual and future needs of power generation industry.