SSS supplies clutch to Indonesia refinery

SSS has received an order for a Size 140T SSS Encased Clutch to connect and disconnect a power recovery turbine (PRT) on a fluid catalytic cracking (FCC) compressor application. The clutch will transmit 23 MW at 3,600 rpm in a machinery train arranged PRT Expander — SSS Clutch — Compressor — Steam Turbine. The clutch is for the FCC Power Recovery Turbine in the Pertamina Balikpapan refinery in Indonesia.

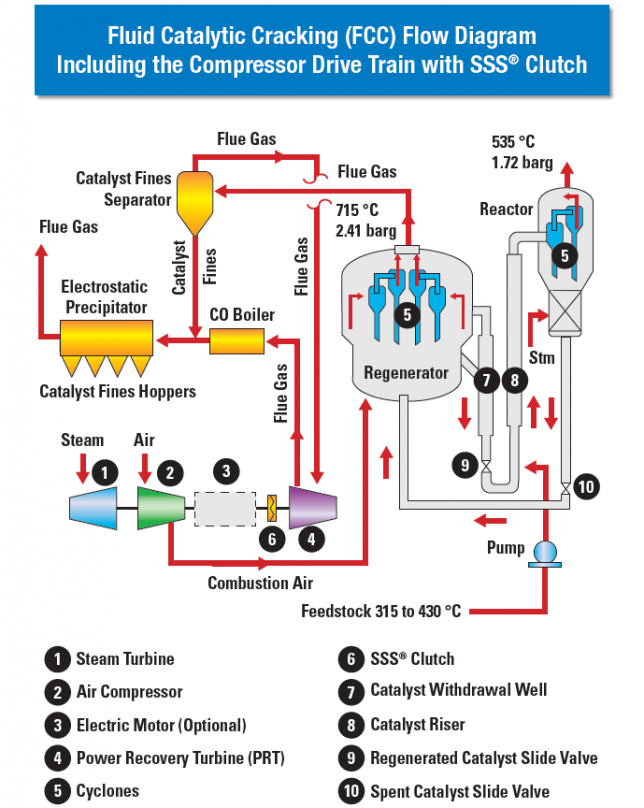

The PRT recovers energy from a stream of approximately 1250 °F, 45 psia flue gas from the FCC process (see diagram), providing all or most of the power required to drive the air compressor, which provides the air required to fluidize the catalyst in the FCC reactor.

The FCC converts a heavy oil feedstock stream to lighter components for the production of gasoline. The flue gas is an byproduct of the reaction and is a combination of carbon monoxide and hydrocarbon gases which is fed through the PRT to a boiler where it is used as fuel to produce steam.

The turbomachinery train for this project includes the PRT, the SSS Clutch, an axial type air compressor and a steam turbine. Oftentimes these trains include a motor/generator (shown as an optional item 3 in the diagram).

Due to the hot, dirty, and corrosive nature of the flue gas, the PRT typically has a shorter maintenance interval than the other train components which can often operate non-stop for over 5 years, compared to 2 to 3 years for the PRT, depending on the quality of the feedstock and catalyst. Process upsets can further shorten the PRT maintenance interval and serious upsets can cause an almost immediate failure. In general, the failures are due to imbalance caused by the buildup of contaminants on the rotor or corrosion stress cracking of the turbine blades.

The addition of the overrunning clutch to the train provides operational flexibility, allowing the PRT to be shut down for maintenance independent of the air compressor and steam turbine. Depending on how the steam turbine is sized the train may be able to run at full output with the PRT shutdown. With an SSS Clutch included, the PRT can be repaired while the air train continues to run, and after the repair can be re-started and re-engaged with the already running compressor train.

The FCC unit is the main gasoline producer in a refinery and shutdown of the FCC unit can cost over $4,000,000 dollars per shutdown event. This is balanced against the value of the recovered power which for a 23 MW PRT can be over $10,000,000 per year.

While not a huge market (about one FCC unit is built every 18-24 months or so), it is generally a high-power application that requires very high reliability and opens up the possibility for adding SSS Clutches to some of the 70 or so existing FCC compressor trains. This high-profile oil refinery application will give SSS Clutches exposure to both the users and the design engineering firms for this and other refinery applications.

Fuel Flexibility in Heavy-Duty Gas Turbines: A Key Driver for Energy Transition

March 13th 2025From Hydrogen to HVO, Mr. Federico Bonzani, Chief Technology Officer of Ansaldo Energia, describes the fuel flexibility state-of-the-art solutions of the Company to meet the actual and future needs of power generation industry.