Steam Turbine Corrosion Protection: Complacency is not an Option

Steam chemistry control is vital to minimize turbine efficiency losses or, in more extreme cases, turbine blade failures with the unit in operation at power plants and co-generation facilities.

Steam chemistry control is vital to minimize turbine efficiency losses or, in more extreme cases, turbine blade failures with the unit in operation at power plants and co-generation facilities.

Common Steam Impurities and Entry Pathways

While any number of impurities can enter steam, the most concerning are sodium, chloride, sulfate, silica, and sometimes copper. The three principal ingress pathways are:

- Carryover of moisture droplets from steam drums.

- Release of volatile compounds from boiler water. Volatilization typically increases with increasing temperature and pressure.

- Direct introduction via steam attemperating water that comes off the boiler feed pump discharge.

Mechanical Carryover

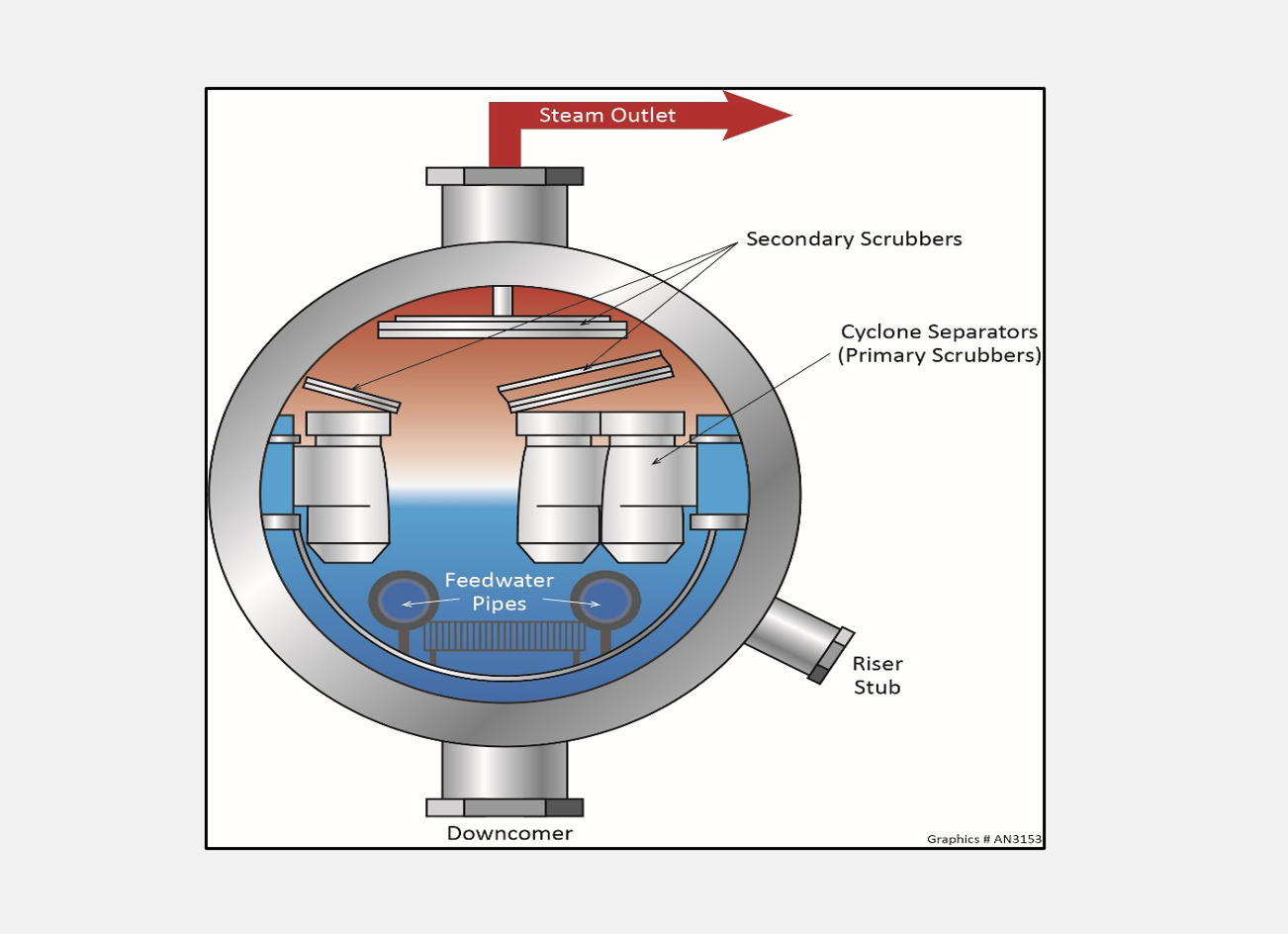

High-purity makeup water is a standard requirement for steam generators with turbines, which includes combined-cycle units with their attendant heat recovery steam generators (HRSGs). Impurities will cycle up to some extent in boiler drums. The compounds are introduced to steam through carryover of moisture. Almost all steam drums are equipped with separating devices to remove entrained water droplets (FIGURE 1).

FIGURE 1. Common steam-moisture separators in a boiler drum1

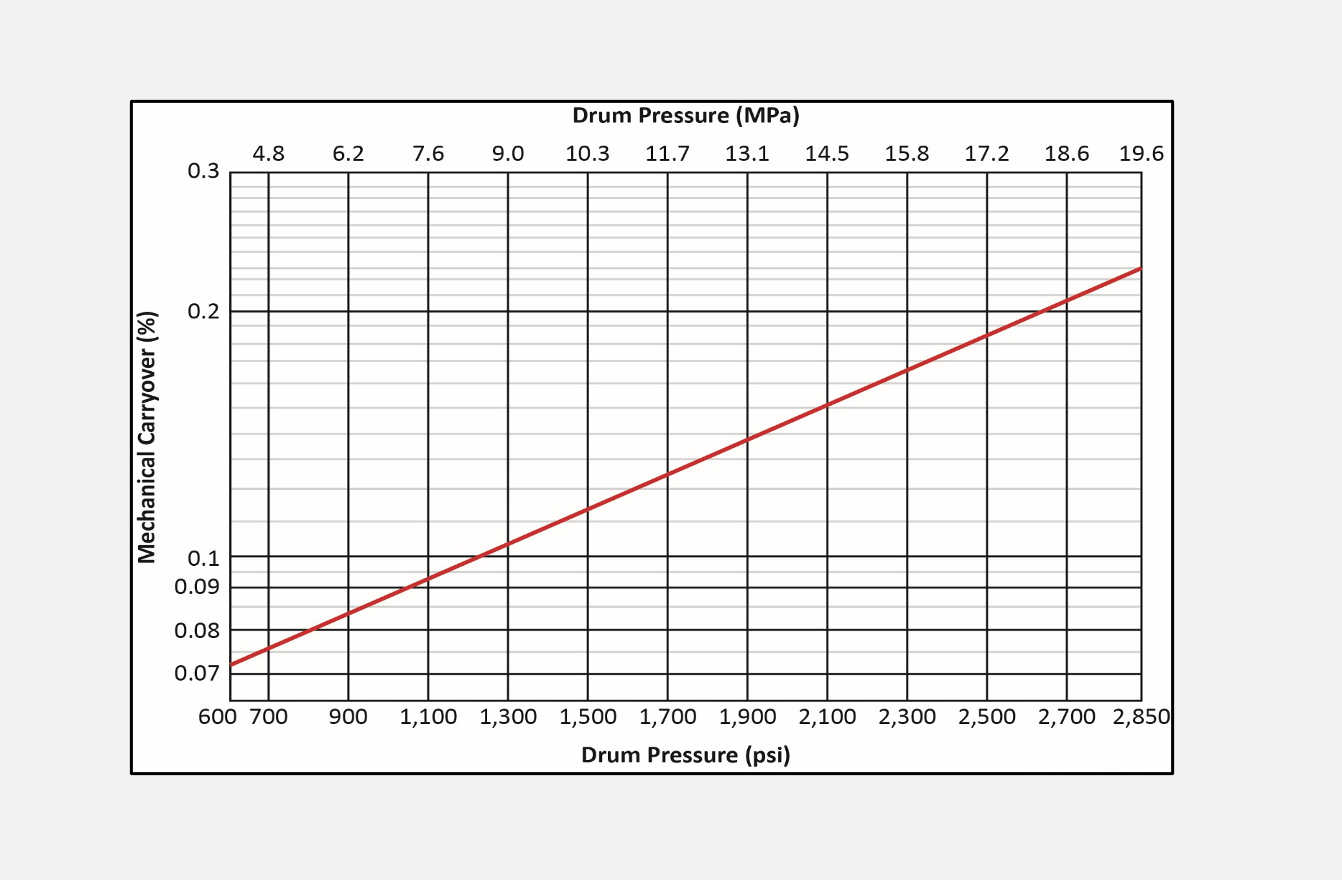

Perfect separation does not exist, and a small amount of moisture will escape with the steam. Furthermore, at higher boiler pressures, the density difference between the boiler water and steam decreases, which lowers separator efficiency as shown in FIGURE 2.

FIGURE 2. General relationship of mechanical carryover vs. boiler pressure1

Periodic boiler water and saturated steam sodium sampling are recommended.2,3 A comparison of the two measurements from samples taken concurrently will provide a reasonable calculation of mechanical carryover.

Mechanical wear and stress also influence separator performance, and a sudden component failure can allow significant moisture ingress to steam. Steam separators and other drum internals should be part of every scheduled maintenance inspection, with maintenance procedures in place to repair damaged equipment.

Vaporous Carryover

Vaporous carryover is defined as the “fraction of substances entrained from boiler water into the steam by the substance’s volatility, [where] only above a drum pressure of about 2,300 psi does vaporous carryover start to become significant for most of the solids dissolved in boiler water. Below this pressure, it is nearly all mechanical carryover except a few substances like silica [and] the copper oxides/hydroxides … .”3 Copper is of much less concern nowadays with the phase-out of many coal-fired units in favor of combined-cycle and renewable generation. The copper in older units came from corrosion of copper alloy feedwater heater tubes.

Steam Attemperating Water

In almost all modern steam-generating power units, main- and reheat-steam attemperation water is taken from the discharge of the boiler feed pump. This water must be very pure, as it offers a direct path for contamination of the steam system and turbine. Ammonia, or in some cases an organic amine or ammonia/amine blend, is the only suitable chemical for feedwater pH control, as solid alkalis such as sodium hydroxide could cause severe and prompt turbine blade and rotor corrosion.

Impurity Concentration Guidelines and Impurity Effects in Turbines

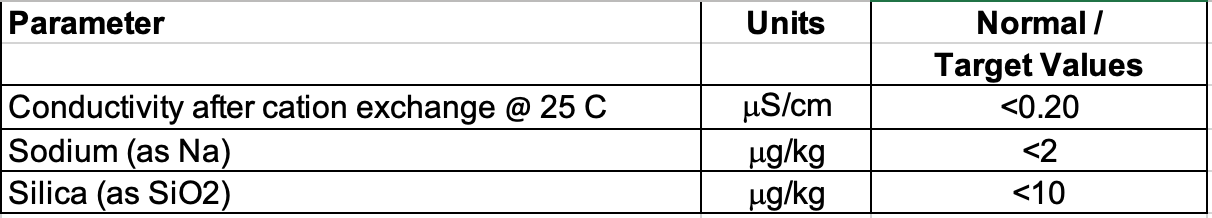

Several research organizations have developed steam purity guidelines. TABLE 1 is the core IAPWS values.

TABLE 1. IAPWS guidelines for turbines receiving superheated steam2

For years, conductivity after cation exchange has served as an indirect measurement of chloride (Cl) and sulfate (SO42-). Online instruments are now available to analyze trace concentrations of these species.4 If Cl and SO42- were included in TABLE 1, the target value would be equivalent to sodium, < 2 μg/kg. (Note: The unit μg/kg is essentially equivalent to parts-per-billion (ppb)). For older steam generators with copper alloy feedwater heater tubes, feedwater chemistry should be controlled to keep the copper concentration at the economizer inlet below 2 μg/kg.

The potential effects of impurities are influenced by the behavior of steam as it passes through the turbine. Steam, of course, expands and decreases in pressure as it flows through and transfers energy to the turbine. Silica and copper become less soluble and precipitate on turbine blades. Neither of these compounds is corrosive, but both will reduce the turbine’s aerodynamic efficiency. The loss of even a few megawatts of capacity during a peak demand period can be quite costly.

Issues related to offline corrosion in low-pressure (LP) turbines often represent the most critical issue. Even with units in world-class chemistry programs, trace quantities of salts such as sodium chloride and sodium sulfate carry over into steam. As the steam releases its remaining superheat energy in the last stages of the LP turbine, moisture droplets begin to form. This region is commonly known as the phase transition zone. Salts will concentrate in the moisture, and during normal operation, these salts are not corrosive. However, during unit outages, if the condenser vacuum is broken and the LP turbine is exposed to ambient air, humidity and oxygen will moisten and activate the salts, which then may initiate pitting on blades, blade attachments, and/or rotors. With repeated cycling, the pits can evolve into microcracks, followed by corrosion fatigue and stress corrosion cracking. The potential outcome is blade failure with the turbine in operation.

Mitigating Steam Contamination and Turbine Corrosion

Controlling steam impurity ingress relies on several methods, some of which have already been outlined. For mechanical carryover, it is important to monitor steam separator integrity to ensure the equipment is not damaged or compromised. From a chemistry aspect, it was already noted that steam separation efficiency decreases with increasing boiler pressure. Accordingly, the allowable concentration of impurities in the boiler water decreases with increasing pressure.

Organizations such as the Electric Power Research Institute (EPRI) have developed detailed guidelines that graphically illustrate the recommended limits of pressure. These guidelines are usually only available to EPRI members and cannot be reproduced here. However, if plant operators and chemists maintain boiler water chemistry within the general recommended guidelines, mechanical carryover should not normally be a serious issue. (Technical guidance documents for steam generators on tri-sodium phosphate or caustic boiler water treatment can be of use.5) Maintaining proper boiler chemistry is also important for minimizing vaporous carryover.

As noted, steam attemperation provides a direct path for impurity ingress to the steam system if feedwater becomes contaminated. The most common source is cooling water leakage in steam surface condensers, although issues from malfunctioning makeup water treatment systems are possible. Such events can also cause severe boiler water chemistry problems. Online chemistry monitoring with immediate alarms to the control room and other locations allows a quick response by operators and technical personnel to identify the upset location and, if necessary, shut down the unit before major damage occurs.4

Protection of LP turbine components from moistened salt corrosion during outages is very important. This issue has become much more prevalent in recent years as units have moved from base load to cycling operation.

As part of an overall program to reduce offline oxygen corrosion in an air system, a case study was published on the practical application of a dehumidified air system that has been utilized for over a decade to protect a two-unit combined cycle plant in Nebraska.6 The study also covers a reduction in flow-accelerated corrosion (FAC) during normal operation—FAC is a serious issue that many plant personnel still do not fully understand.

Conclusion

Even seemingly minor impurity ingress to steam turbines may cause major problems if the issues are overlooked or if steam generator chemistry is neglected. A key takeaway is that any steam-generating system should be equipped with online chemistry instrumentation to give plant personnel or outside experts the capability to monitor normal chemistry 24/7 and to quickly respond if upsets occur.

REFERENCES:

- Water Essentials Handbook (Tech. Ed.: B. Buecker). ChemTreat, Inc., Glen Allen, VA, 2023.

- International Association for the Properties of Water and Steam, Technical Guidance Document: Steam Purity for Turbine Operation (2013).

- International Association for the Properties of Water and Steam, Technical Guidance Document: Procedures for the Measurement of Carryover of Boiler Water into Steam (2008).

- B. Buecker, “Monitoring of Water and Steam Chemistry for Steam Generators”; Chemical Engineering, September 2019.

- International Association for the Properties of Water and Steam, Technical Guidance Document: Phosphate and NaOH treatments for the steam-water circuits of drum boilers of fossil and combined cycle/HRSG power plants (2015).

- Buecker, B., and D. Dixon, “Plant Combats Corrosion in Idled Boilers”; Chemical Processing”, September 2016.

ABOUT THE AUTHOR

Brad Buecker is president of Buecker & Associates, LLC, a consulting and technical writing/marketing. He can be reached at beakertoo@aol.com.