STEAM TURBINES

GENERAL PURPOSE STEAM TURBINE UPGRADES

BY HEINZ BLOCH & RICHARD SMITH

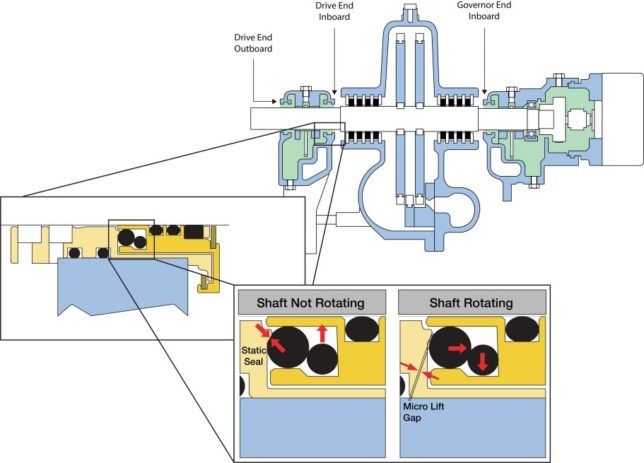

It is not unusual for large oil refineries to have 160 general purpose (GP) steam turbines installed at a major site. Return-on-investment (ROI) studies and related cost assessments indicate that major refineries may have opportunities to capture steam turbinerelated corporate-wide maintenance savings in excess of $3,000,000 annually. The two areas worth exploring are bearing protector seals and cartridge-style steam glands wherein high temperature mechanical seals replace the century-old segmented carbon ring technology. These issues are of great importance to reliability- focused refineries, fertilizer producers and petrochemical plants to prevent steam from entering the bearing house (Figure 1).

Bearing protector seals can virtually eliminate premature bearing failure. These seals achieve contaminant and vapor exclusion by incorporating an axially-moving O-ring. In addition to preventing bearing distress, upgrading to such seals may prevent fires caused by leaking into the bearing housing. Similarly, cartridge-style high temperature mechanical seals can greatly reduce maintenance frequency, and ultimately, the cost of leakage-related turbine failures. Focus on bearing housing protector seals Steam intrusion often occurs, for example, when steam gland and bearing housing are adjacent to each other.

Lubricating oil can become contaminated by steam blowing past the carbon rings in the shaft glands. The contaminated oil requires periodic discarding and must be replaced by fresh oil. As a precautionary activity, water must be drained off in an effort to extend bearing life and machine reliability. However, by the time free water collects and is visible in a sampling line or sight glass, dissolved water will exist and often cause additives depletion through a process called partitioning.

The additives partition themselves between the oil and water phase in proportions that largely depend on their relative solubilities. When free water is removed from the oil by gravity, polymer absorption or centrifuging, these additives are lost. The loss deprives the oil of the protection normally given by anti-rust and anti-oxidant inhibitors.

Moreover, water will combine with airborne dust to form sludge. Periodic manual removal of water, then is a technically inferior approach. Better strategies are vacuum dehydration, coalescing and air sparging. However, all involve cost. It may be simpler and more cost effective to prevent water intrusion through use of bearing housing protector seals.

The American Petroleum Institute’s Standard for General Purpose Steam Turbines in the Petroleum, Chemical and Gas Industries (API-611) has several clauses that apply to bearing housing seals:

6.10.4.2.1 Bearing housings shall be equipped with replaceable labyrinth-style end seals and deflectors where the shaft passes through the housing; lip-type seals shall not be used. The seals and deflectors shall be made of non-sparking materials. The design of the seals and deflectors shall effectively retain oil in the housing and prevent entry of steam, condensation and foreign material into the housing. 6.10.4.2.1 (Option): <> If specified, bearing isolation seals providing a positive tight seal to prevent the ingress of atmospheric contaminants shall be supplied.

Replaceable rotating labyrinth devices can be installed in existing machines without bearing housing modifications. Unlike traditional fixed labyrinths, they use centrifugal force to expel potential contaminants before they reach the oil. During periods of operational idleness dynamic (axially moving) vapor-blocking O-rings provide a secondary level of protection and compliance with the requirements in API-611, paragraph 6.10.4.2.1. Lubrication protection must be effective when the equipment is running and when not in operation. With traditional labyrinth seals, moisture aspiration occurs. As the equipment cools, the surrounding ambient air is drawn into the bearing housing.

To prevent moisture ingress, a vapor shut-off device is needed. This shut-off feature is often overlooked in seal designs. A well-engineered bearing housing seal prevents moisture ingress. Temperature resistance is achieved by using graphite foil secondary shaft seals (Figure 2).

Figure 2: Location of bearing housing protector seals. Note the large cross-section O-ring which seals against a static seat if the shaft is stopped and provides an axial micro-gap with shaft operating.

It is best to incorporate a bearing housing protector upgrade into the normal steam turbine maintenance cycle rather than a pre-planned removal cycle. Hundreds of these seals operate in general purpose steam turbines manufactured by Elliott, for example. Many were retrofitted to steam turbines from legacy equipment manufacturers that included Dresser-Rand, Terry, Skinner, and Worthington. Throughout the world, these seals are now installed in a wide range of steam turbine sizes. The lube application details in these machines often differ.

Take the case of a non-pressurized splash lubrication system (also described as a turbine bearing housing with an oil sump) at a large facility in the Southern United States. The oil sump capacities ranged from two to six liters with no provision for filtration. Oil changes had to be done every two months. After the bearing housing protector seals were added, oil changes would take place about three times every decade. The payback period, therefore, was short.

Cartridge-style steam glands

For about one hundred years, small steam turbines have incorporated bushing-type single-piece and/or segmented carbon gland components to reduce or, hopefully, prevent steam leakage along the shaft. However, comprehensive leakage prevention has never been achieved with old style glands. This was due to turbine shafts being made from steel; its coefficient of thermal expansion differs from that of carbon. As a small amount of steam rushes through tiny gaps at sonic velocity, an erosive effect known as “steam cutting” causes the gap to widen. Physics, thermodynamics and hydraulics combine to explain the interacting processes.

In the late 1970s, it was discovered that clean steam can be introduced to create the thin fluid layer between stationary and rotating seal faces in dry gas seals. This fact led, in the early 1980s, to in-plant research and cost justifications initially favoring alloy steel bellows seals in lieu of snug-fitting carbon in the gland area. The carbon rings in the glands of several small steam turbines were discarded and replaced by bellows-type high-temperature gas seals. As a result, steam turbine maintenance costs and steam losses were reduced along with a decline in reported bearing distress events.

The success of high-temperature mechanical seals as upgraded glands in small steam turbines required fitting “loose” parts from so-called component seals. This made mechanical seal-based glands more difficult to assemble than traditional segmented carbon glands. More recently, an upgrade option became available that replaces the old steam turbine gland seal. Cartridge versions can point to years of solid operating experience. Assembly by the user-purchaser is no longer needed as the parts are cartridge-mounted by the manufacturer and shipped ready for installation. The latest high-temperature steam seals utilize dry-running compressor gas seal technology.

As dry gas seals (DGS) have demonstrated effectiveness in lowering maintenance costs for gas compressors, their successful migration to other fluid machines and application in small and medium-sized steam turbines was foreseeable. Aging steam turbines With an aging population of steam turbines existing inside most refineries, maintenance requirements are destined to rise dramatically. Unfortunately, the presence of stationary labyrinth seals and segmented carbon gland components will add to the maintenance burden. These components are ineffective in preventing moisture ingress and contamination of the lube oil. Replacement with the latest bearing housing protector and DGS-based steam gland seals is a way to minimize maintenance costs and extend steam turbine life.

Heinz P. Bloch is a consulting engineer in Colorado who first entered the work force in 1950 and graduated with BSME and MSME degrees in 1962 (heinzpbloch@gmail.com). For more information: Bloch, Heinz P. and Hurl Elliott, Mechanical Seals for Medium-Pressure Steam Turbines, presented at the ASLE 40th Annual Meeting in Las Vegas, NV, May 1985 (reprinted in Lubrication Engineering, November 1985; and Bloch, Heinz P., Petrochemical Machinery Insights, (2016) Elsevier Publishing. Richard Smith (richard.smith@ aesseal.co.uk) is a seal application and design expert with over 30 years of professional experience in the field of sealing. He has held executive positions with AESSEAL for decades, a company specializing in mechanical seals and support systems. For more information, visit www.aesseal.com