SUPERCHARGED GAS TURBINE POWER PLANT

LESS EXPENSIVE TO MANUFACTURE AND OPERATE THAN A COMBINED CYCLE PLANT

By LEE S. LANGSTON

The comparatively recent development and deployment of natural gas fueled combined cycle gas turbine (CCGT) power plants represents a historic breakthrough in efficient energy conversion. The combination of a modern GT driving an electric generator to produce a hot exhaust to generate steam to drive a steam turbine (ST) for more electricity has doubled the efficiency of power plants in less than a generation.

The newest CCGTs are exceeding power plant thermal efficiencies of 60%. Gas turbine OEMs, such as Siemens, GE and Mitsubishi, are shooting for 65% in their most advanced designs.

One can argue that Sadi Carnot (1796- 1832), the young French engineer who authored the essay Reflections on the Motive Power of Heat, had the earliest thoughts for a combined cycle plant. In an 1824 essay he wrote:

“Air, then, would seem more suitable than steam to realize the motive power of falls of caloric [of a given temperature difference] from high temperatures; perhaps at low temperatures steam may be more convenient. We might conceive even the possibility of making the same heat act successively upon air and vapor of water. It would be only necessary that the air should have, after its use, an elevated temperature, and instead of throwing it out immediately into the atmosphere, to make it envelop a steam boiler [heat recovery steam generator], as if it issued from a furnace.”

So here we are some 200 years after Carnot’s speculations on the combined use of air and steam as working fluids, with combined cycle plants that are the most efficient heat engines in mankind’s thermodynamic history.

CCGT shortcomings

Even with mankind’s centuries-old history of working with steam power, CCGT plants present challenges to OEMs, owners and operators. Contrast the simpler operation of a single phase (air) Brayton cycle GT plant with that of the more complicated two-phase (steam and water) operation of a Rankine cycle steam plant (consisting of a boiler, ST, condenser and water treatment facility).

In designing and fabricating a CCGT, an OEM must maintain engineering and manufacturing staff who have expertise in both gas turbines and the older, more mature areas of STs, HRSGs, and condenser design. CCGT plant owners and operators cover the relatively simpler operation of GTs, but also must deal with all that is needed to keep a steam plant in operation.

With its exhaust to the atmosphere and straightforward design, its manufacture and operation more trouble free, an open cycle gas turbine (Figure 1) is more cost effective, both for capital costs and operation expenses, than a steam power plant. However, it will not match the superior thermal efficiency of a CCGT.

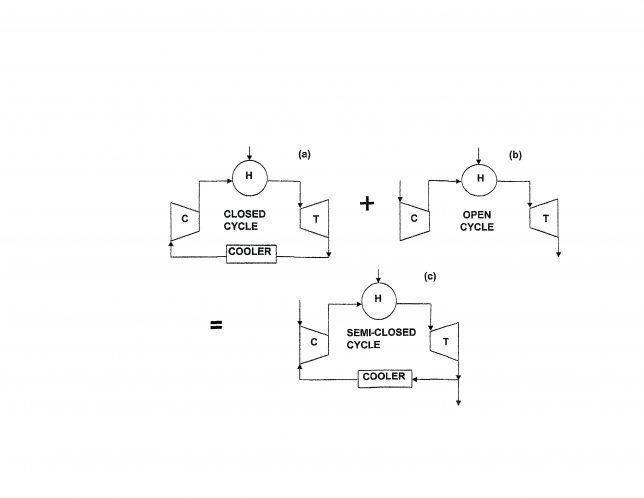

Figure 1: A semi-closed cycle gas turbine is the combination of a closed and open cycle gas turbine. (From Advanced Gas Turbine Cycles, by J. H. Horlock, Pergamon, 2003)

At Turbo Expo 2014 in Düsseldorf, author Hans Wettstein, who has had over 30 years on Brown Bovari, ABB and Alstom’s engineering staff, presented a paper proposing a thermodynamic cycle with a supercharged gas turbine (GT2014-25134, The Semi-Closed Recuperated Cycle with Intercooler Compressors). Along with the promise of higher efficiencies over a wide range of loads, supercharging would provide more power to a GT of a given size, just as it does for diesel and Otto engines. One 400 MW supercharged GT power plant variant analyzed by Wettstein yielded a predicted thermal efficiency of 60%, rivaling current combined cycle values, with none of the complications of a steam cycle.

To understand Wettstein’s supercharger analysis, consider again a closed cycle gas turbine (Figure 1) where a working fluid (air, but it could be helium, and so on.) is recirculating without any internal combustion. Approximating a thermodynamic Brayton cycle, the closed cycle gas turbine has two heat exchangers, one for rejecting heat from working fluid entering the compressor and one for energy addition to flow entering the turbine. The latter is heated by an external energy source, such as combustion, a solar collector or a nuclear reactor. Some 24 closed cycle electrical power plants were installed, mostly in Europe, from 1940 into the 1980s.

Closed cycle problems

The chief disadvantage of the closed cycle GT is that the allowable working temperatures of heat exchanger surfaces impose a low upper limit in the cycle, keeping achievable cycle thermal efficiencies in the 20 to 30% range. Moreover, the heat exchanger must be large compared to other components, amounting to as much as 40% of plant capital costs.

Consequently, open cycle large GTs operating at much higher maximum temperatures can have thermal efficiencies in the 40-50% range, and dominate in GT power plants. The higher open cycle temperatures are realized by using combustors directly and by using compressor air for cooling hot section parts. Thus we have seen little modern use of closed cycle GT plants, except those that have been proposed recently for use with high-temperature, gas-cooled nuclear reactors.

The part-load characteristics of a closed cycle GT are remarkably better than those of open cycle operation. In closed cycle operation, load reduction is achieved by bleeding the working fluid from the closed loop. This reduces the mass flow rate, cutting system pressures, lowering gas density, and lowering power output, but maintaining constant gas velocities at constant rpm. In GT designer terminology, the turbomachinery velocity triangles remain the same, so that closed cycle design efficiency will remain the same over a wide range of load operations (load addition is accomplished by the addition of the working fluid to the closed loop).

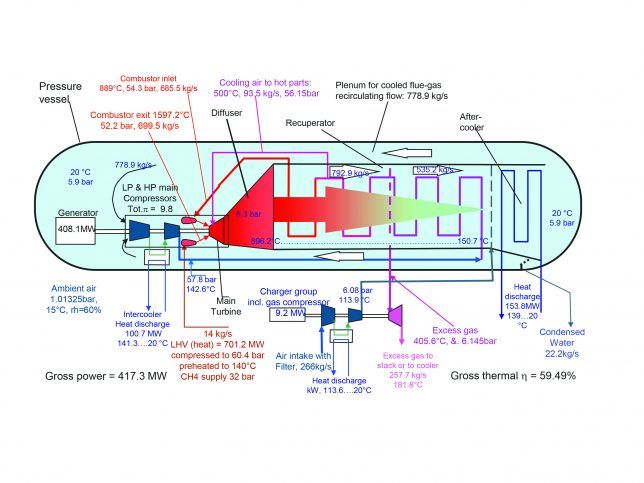

Figure 2. Supercharged semi-closed cycle gas turbine power plant. Courtesy of Hans Wettstein

Semi-closed cycle

The supercharged gas turbine power plant proposed by Wettstein is a semi-closed (SC) cycle (Figure 2). The SC cycle is an amalgamation of closed and open cycles. It consists of a GT having an internal combustor for energy input to the cycle.

Part of the exhaust is rejected to the atmosphere, with the remainder recirculated into the compressor. Atmospheric air is also introduced into the compressor to maintain a desired mass flow rate and provide makeup oxygen to sustain combustion.

One can go through a simple illustration to show that given similar conditions for both open and closed cycles, a semi-closed cycle should have approximately the same efficiency as either. However, with an SC cycle, a designer now has some of the best features of both open and closed to move SC power plant operation in different directions.

With internal combustion, the SC cycle is not constrained by the temperature limitations of the closed cycle. Also, the SC cycle will have the favorable part load efficiencies of the closed cycle if pressure levels can be varied. Wettstein introduces a supercharger to the SC cycle. He also includes cycle study thermodynamic data at appropriate points. If one carefully follows these, a picture emerges of SC cycle details.

This SC unit is enclosed within a common pressure vessel at a relatively moderate pressure of 5.9/bar (86 psia or 5.8 atm). Starting at the low compressor inlet, gas is introduced at 20°C and 5.9 bar from the surrounding pressure vessel. Since this is a SC cycle, the gas mass flow consists of a cool turbine exhaust (66%) and supercharger provided air (34%), with a ratio of exhaust-to-fresh air of 2:1. Gas path flow then passes through the low compressor through an intercooler and into the high compressor for a total compression ratio of 9.8:1. High compressor exiting gas flow then enters the recuperator.

It is preheated by turbine exhaust gas before it enters the combustor where combustion takes place with natural gas as the fuel. From the combustor, hot gases enter the turbine which drives the compressor and the 400 MW electrical generator. The resulting exhaust gases enter the recuperator to preheat the compressor flow before it enters the combustor. At some point in the recuperator, exhaust gases are withdrawn to power the turbine of the supercharger. This exhaust gas portion can be discharged up the exhaust stack.

This turbine powers the supercharger compressor which supplies fresh air to the SC cycle, and just as important, controls the pressure level in the common pressure vessel. Finally, as exhaust gases exit the recuperator, they mix with fresh supercharger air.

As required by Second Law of Thermodynamics, the mixed exhaust gases are cooled (heat rejection from the cycle) by a heat exchanger to remove combustion-produced water vapor and to lower the temperature of the inlet gas turbine compressor flow to the specified 20°C.

Promising concept

Wettstein’s design study for this supercharged semi-closed gas turbine cycle shows great promise. At an output 417 MW, the calculated thermal efficiency is 60%. As pressure levels can be varied, part load output can be controlled independent of turbine inlet temperature. This design would take advantage of existing GT components.

CCGT levels of thermal efficiency can also be matched without the need for steam technology. Wettstein’s analysis reveals that a supercharged gas turbine could be less expensive to manufacture and operate than a CCGT, while offering equally high thermal efficiency.

What we need is for a pilot supercharged gas turbine power plant to be constructed to validate and verify the analysis.

Author: Lee S. Langston is Professor Emeritus for Mechanical Engineering

at the University of Connecticut. For more information, langston@engr.uconn.edu (860)486-4884