Svanehøj’s CO2 Pumps to Facilitate Carbon Storage at Project Greensand

INEOS, Royal Wagenborg, and Royal Niestern Sander shipyard will develop a liquefied CO2 carrier, expected to enter service by year-end 2025.

Under a contract granted by INEOS, Svanehøj will supply CO2 pumps to a Port Esbjerg-based onshore facility and liquefied CO2 (LCO2) carrier for Project Greensand, offshore Denmark in the North Sea. The project’s initial storage capacity is 400,000 tons of CO2 annually and, after successful trials, will scale up to 8 million tons per year. Full-scale operations are expected to commence in Q4 2025 or Q1 2026.

“We have worked closely with INEOS’ development team over the past year to specify customized pump solutions for both the onshore terminal and the vessel,” said Magnus Madsen, Sales Manager, Cargo Gas at Svanehøj. “It has been a rewarding process, allowing us to leverage our expertise in CO2 and contribute to an optimized design.”

Project Greensand

Project Greensand is a full CO2 storage chain, named after the subsea sandstone formations in which the CO2 will be permanently sequestered. It will capture, liquefy, and transport CO2 emitted by Danish biogas producers, injecting the pollutant into depleted oil wells across the Nini Field. Offshore operations will be supported by INEOS, Royal Wagenborg, and Royal Niestern Sander shipyard, developing an LCO2 carrier with:

- An EasyMax vessel design

- High load capacity

- Low fuel consumption

- Expected to enter service by year-end 2025

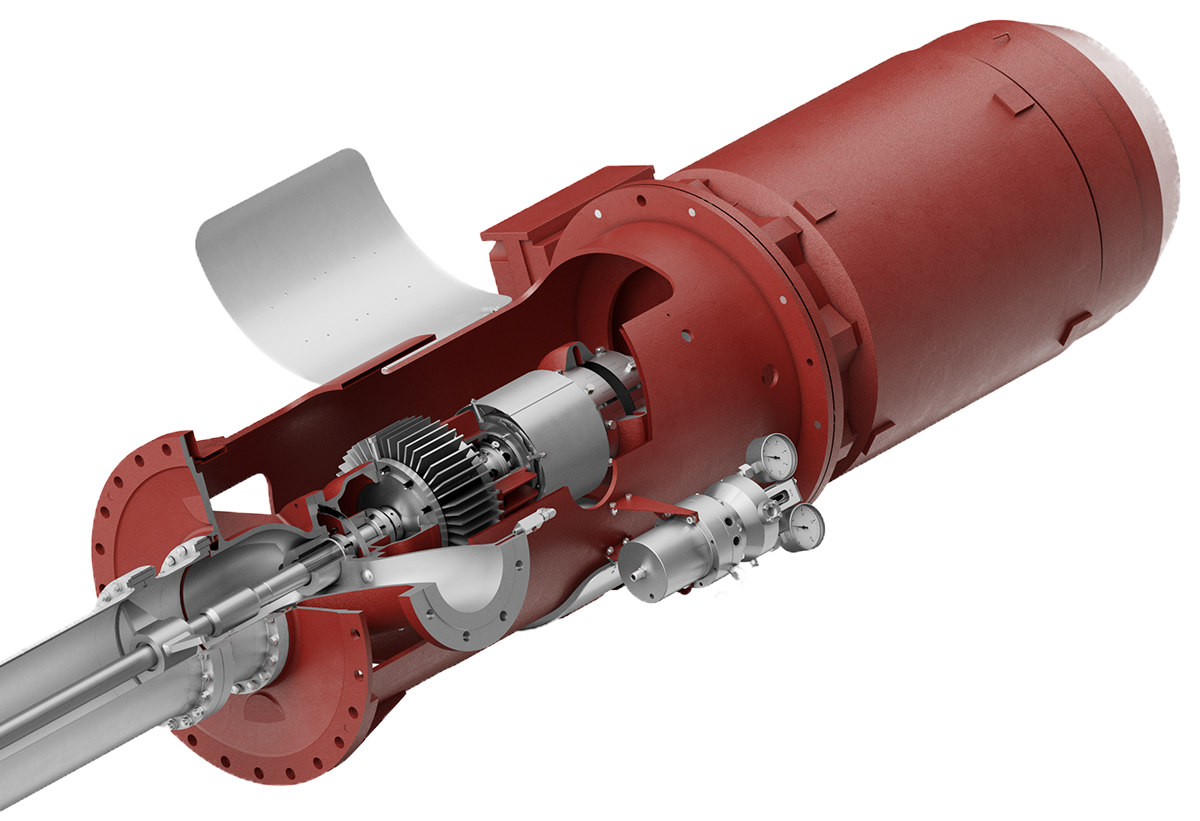

CO2 pump; image credit: Svanehoj

The project supports Denmark’s goal to develop carbon capture and storage (CCS) with existing offshore infrastructure – by 2030, the country plans to lower greenhouse gas emissions by 70%. Funding programs and regulations from the Danish government support CO2 transport and storage, establishing Denmark as a CO2 management hub in Northern Europe.

More Svanehøj News

In early September 2024, Svanehøj developed a dedicated high-pressure ammonia fuel pump, the HP NH3 Fuel Pump, capable of fuel injection pressure up to 100 BAR. It is based on the company’s deepwell low-pressure fuel pump, some of which are used for marine-based ammonia fuel applications. The HP NH3 Fuel Pump has a small footprint—2,100 x 780 x 1,450 mm—and can fit the tank connection space (TCS) in an ammonia fuel supply system.

For maintenance operations, the pump is fully drainable and can be lifted out in one piece. It contains a media-lubricated, easily changeable ceramic ball bearing for axial loads. In terms of power transmission, Svanehøj uses a heavy-duty drive with a carbon-reinforced, accessible timing belt system. The HP NH3 Fuel Pump has flow measured at 37 m3/h and a discharge pressure of 85 BAR.

In July, Svanehøj received a contract to provide deepwell ammonia fuel pumps for eight bulk carriers owned by a maritime shipping and logistics group. The pumps will deliver a reliable fuel supply and are compatible with all liquefied gas fuels, including LNG, LPG, methanol, and ammonia. Svanehøj will deliver the first two pumps in 2024, fulfilling the complete order in 2025.

These commercial bulk carriers are, according to the company, the first vessels of their size capable of ammonia-fueled operation. They will be outfitted with a dual fueling system of traditional diesel oil and clean fuel. The fuel pumps enable the vessels to use ammonia and additional sustainable fuels.