THE HYDROGEN TURBINE

RECONFIGURING BHGE’S NOVALT GAS TURBINE FOR 100% HYDROGEN DUTY

BY DREW ROBB

Gas turbines (GTs) running on 100% hydrogen have been a long-term dream (Turbomachinery International Nov/Dec 2018). The concept has gained momentum in tandem with the trend toward carbon neutrality. Now that coal-powered facilities are being legislated out of existence in many countries, attention has turned to finding ways to transition natural gas-fired turbines over to alternate fuels.

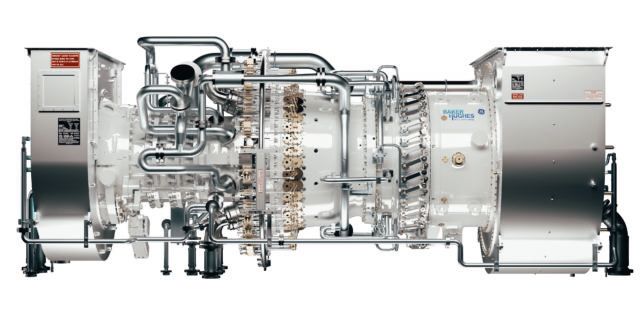

Baker Hughes GE (BHGE) is working to bring the 100% hydrogen dream to reality. It has signed an agreement with Australian hydrogen infrastructure developer H2U to modify a NovaLT GT to run solely on hydrogen at a green hydrogen power facility in Port Lincoln, Australia. “NovaLT generators were chosen because they could operate on 100% hydrogen at all times,” said H2U CEO Attilio Pigneri. “The annular combustor design and dual-shaft configuration will enable the unit to deliver black-start capability while still operating on 100% hydrogen.”

H2U is building a 30 MW water electrolysis plant, as well as a facility for sustainable ammonia production near Port Lincoln. The Port Lincoln Project includes a 15 MW electrolyzer plant, distributed ammonia production facility, 10 MW hydrogen-fired GT, and a 5 MW hydrogen fuel cell. This will make it one of the first commercial plants to produce carbon dioxide- free green ammonia that can be used as an industrial fertilizer for farmers and aquaculture operators.

The Port Lincoln plant is situated beside a facility that produces ammonia from hydrogen via electrolysis. Some of that hydrogen can be deployed for peaking power when there are favorable market conditions, or as standby power in the event of a grid outage. The plant can either use grid supply, on-site solar power or hydrogen-powered electricity as required.

With no natural gas pipeline infrastructure nearby, hydrogen-powered turbines were the best option. Up to two BHGE NovaLT16 GTs will operate at the facility, which will be able to produce up to 40 MW.

“The NovaLT 16’s annular combustor is needed to startup and progressively fire up hydrogen generation without misfires,” said Pigneri. “As it is an aeroderivative gas turbine, it can withstand high temperatures, is easy to maintain, and can ramp rapidly.”

BHGE is building on its experience with hydrogen-fueled gas turbine combustion system developed for the Fusina plant in Venice (Italy) to ready the NovaLT16 for the H2U project. The combustion chamber will be modified to run on 100% hydrogen. BHGE plans to tune the design with a full-scale annular rig test at the Sesta Laboratory in Italy, as well as with single-capacity tests in its Florence facilities. Final validation of the modified combustor will be done in the prototype engine.

In addition, control software will be adjusted and minor improvements will be made to the package. NOx emissions of the hydrogen-fired turbine will be managed within acceptable limits. “The capability to ramp up within minutes is critical as the Australian grid operates at five-minute intervals,” said Luca Maria Rossi Chief Technology Officer of Turbomachinery Process & Solutions at BHGE. “The NovaLT16 turbines will support critical loads within the Port Lincoln facility, while also contributing generation to the grid during periods of low wind or solar output.”

Construction at Power Lincoln will begin in 2020 with commissioning and commercial operation slated for either late 2020 or early 2021.

BHGE and H2U sign deal to deploy the NovaLT gas turbine at Australian plant. From left to right: Luca Maria Rossi and Rod Christie, BHGE; Attilio Pigneri and Tristram Travers, H2U