Titan 250

SOLAR TURBINE’S TITAN 250 GAS TURBINE CAN BURN A VARIETY OF FUELS WHILE ACHIEVING LOW EMISSIONS LEVELS

The Titan 250 gas turbine system and matching gas compressor family are the latest additions to the Solar industrial gas turbine product line. The launch unit was started in 2009 with a C85 compressor set installed at a natural gas transmission site in Tennessee. Since then, it has been applied in onshore and offshore applications, driving gas compressors and generators.

The unit produces 30,000 horsepower (22.3 MW) of shaft output at 40% efficiency. Its design leverages core aerodynamic, material and cooling technologies that have been successfully used in over 14,800 units in the field.

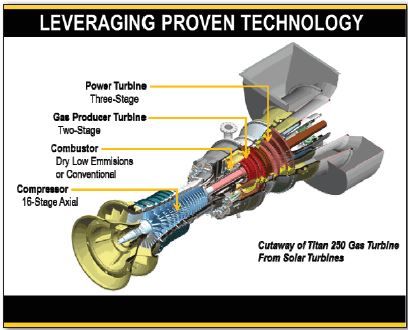

The Titan 250 gas turbine is designed as a two-shaft model with a 16-stage, axial-flow compressor with a pressure ratio of 24:1, a dry-low emissions or conventional combustion system, a twostage gas producer turbine operating at a firing temperature of 1,204°C and a three-stage, all-shrouded blade power turbine (Figure 1).

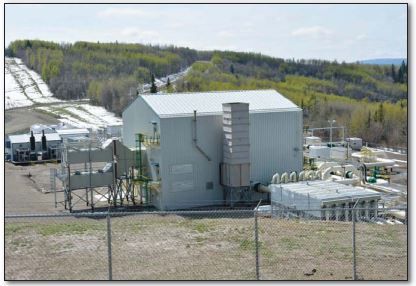

Figure 1: A Titan 250 gas turbine compressor set was installed to increase capacity at this gas transmission station in northeastern British Columbia, Canada

The operating cycle and mechanical design is similar to that of the 15 MW Titan 130 gas turbine. Aerodynamic modelling techniques were implemented to establish flow path and airfoil component designs and were based on earlier models. The lean-premix combustion system operates at the same firing temperature. The backside cooled combustor liner, as well as the gas producer turbine nozzles and blades, use cooling arrangements similar to previous models.

The Titan 250 combines performance, robustness and uptime. Its modular design permits either complete engine exchanges for overhaul, the exchange of components, or field service repair performed on site. Additional and redundant instrumentation, in concert with a suite of monitoring options, are used to minimize non-critical shutdowns and alarms and to provide diagnostics and equipment health monitoring capabilities.

On the package side, availability was increased by features such as larger dualoil filters with three times the debris carrying capacity of previous designs. An evaluation program, in conjunction with a number of suppliers, has led to a wider range of air-inlet filtration options. The lean-premix combustion system used in this engine can meet NOx and CO regulation requirements over across the load and temperature range.

Figure 2: The Titan 250. Photo courtesy of Solar Turbines

Solar Turbines has also developed a family of five high-efficiency centrifugal gas compressors to be driven by the Titan 250’s output power and shaft speed. The C41, C51 and C61 multistage compressors are for upstream processing and production applications in the oil and gas industry. They are geometrical scales of the C51 compressor introduced earlier by Solar. Like all current Solar gas compressors, they use pre-engineered components.

In addition, the C85 and C75 pipeline compressors were developed for pipeline applications and are scaled-up versions of smaller models. The C85 is available with one or two impellers and the C75 is available with one, two, or three impellers, depending on the project specific head and flow requirements.

Field testing

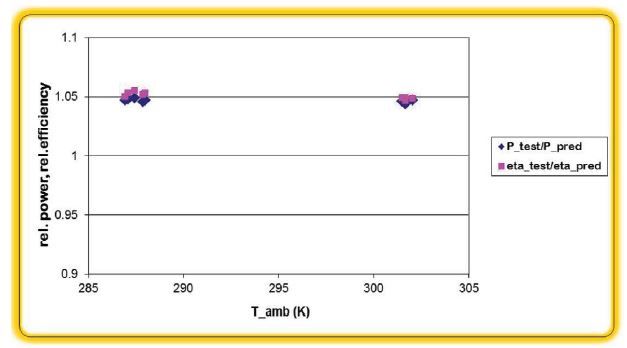

A Titan 250 driving a Solar C85 pipeline compressor underwent extensive field testing after being installed and commissioned at a compressor station in Germany. The engine’s produced power was measured with a torque meter and by the compressor’s absorbed power. For a range of ambient temperatures, power and efficiency showed acceptable values. Engine test data was taken at two different ambient temperatures (18.9°C and 28.6°C, respectively). Both power and efficiency exceeded the predicted and committed values.

In the 30,000 to 60,000 horsepower range, two different types of gas turbines are available: aeroderivative gas turbines and industrial gas turbines. Aeroderivative gas turbines were originally designed for the aviation industry and later modified for land-based applications; industrial gas turbines were first engineered for power generation or mechanical drive applications.

Traditionally, the aeroderivative gas turbine is regarded as having excellent fuel efficiency and straightforward maintainability, while the industrial gas turbines have the reputation for robustness and having a cleaner combustion system. The Titan 250 blends both worlds to provide a turbine capable of burning a variety of fuels while achieving low emissions levels.

Figure 3: Engine output power and thermal efficiency at full load, compared with predicted values[/caption]