TORQUE SENSORS

IN-LINE TORQUE SENSORS CAN HELP INCREASE TURBOMACHINERY EFFICIENCY

By MARK E. MINDA

The first phase of any effort to boost the efficiency of a piece of machinery is gathering accurate data on the machine’s initial performance, particularly torque data. Only then can you lower its operating costs and reduce power consumption However, the nature of turbomachinery can make it especially challenging to measure torque accurately. Electric motors, pumps, compressors and turbines can all generate high torque at high RPMs. In addition, torsional vibration can sometimes lead to premature failures in the driveline. Historically, this has created limitations on how torque can be measured both accurately and safely.

Torque is defined as the amount of force needed to rotate an object about an axis, fulcrum or pivot. The mathematical equation for torque is force multiplied by distance. To illustrate, imagine a foot-long lever arm attached to the center of a wheel; if hanging a one-pound weight on the end of the lever arm makes the wheel turn, the force needed to turn the wheel can be described as 1 lb-ft of torque.

Methods of measurement

Ensuring accurate torque measurements is not always a straightforward process. There are a variety of physical influences involved and there are multiple measurement methods, each of which has its advantages and disadvantages. One approach is measuring input current to a motor. Its main advantage method is that it is inexpensive to implement by attaching a digital multimeter to the cable powering the motor exerting torque. Engineers can then use the data acquired to calculate consumed electrical power, output mechanical power, angular speed, motor efficiency, and finally, the amount of torque produced. The biggest problem is that it is not accurate, so it is best used only for quick-and- dirty torque measurements.

Strain gauging a rotating shaft is another method. This technique is inexpensive to implement because there is no need to modify the driveline. All that is required is to attach a strain gauge to the rotating shaft. Acquiring the data from the rotating shaft typically requires a slip-ring assembly or telemetry system. The high number of variables and unknowns involved complicate calculating torque based on strain gauge data.

Reaction Sensors

The advantage of this sensor type, which is < 0.5% accurate, is that there is no need to cut the driveline in two to insert an in-line torque sensor. This makes it easier and less expensive to implement. However, the downside of this approach is that the measurements produced are far less dynamic than those produced by in-line rotating torque sensors because the data tend to be averaged by the mass of the dynamometer.

In-line rotating torque sensors offer the highest measurement accuracy and the most dynamic measurements, but they are also the most expensive to implement because have to be inserted into the driveline. In-line rotating torque sensors have been around for roughly half a century, with a variety of technical advancements introduced to sensor design over the last few decades. This includes more choices on how to measure dynamic torque.

Some of the newest in-line torque sensors support linearity and hysteresis errors of <0.03% of full scale with response times in excess of 3 kHz. The automobile industry has been using dynamic data acquired from in-line torque sensors for decades to improve powertrain performance, efficiency and longevity by informed design decisions.

Figure 1. HBM’s new T40HS high-speed in-line bearingless torque sensor

Over the last twenty years, bearingless in-line torque sensors (Figure 1) have become the standard for in-line torque measurement. A bearingless design allows for greater accuracy, higher RPM capability, and 24/7 operation with little or no sensor maintenance. A combination of digital telemetry and digital electronics helps to reduce noise, increase resolution and improve torque sensor performance. The use of titanium rotors allows for design of in-line bearingless torque sensors capable of up to 45,000 RPM. This is well above the capabilities of a typical strain gauge-based torque sensor but is necessary for applications like turbine fan blade testing.

Today, custom torque sensor designs are helping to meet the growing demand for instrumentation suitable for characterizing high-horsepower turbine engines, with sensors capable of measuring torque greater than one meganewton meter (1MNm) now available. Most bearingless torque sensors use foil-strain gauges as the means of measuring stress. They are configured and wired in what is known as a Wheatstone bridge.

A voltage (preferably an AC voltage to improve noise immunity) is applied to the circuit. This is known as an AC carrier frequency amplifier. When the sensor experiences mechanical torque, the resistance of the Wheatstone bridge changes and produces an analog voltage that is proportional to the torque applied. As the rotor and stator are not in physical contact with each other, the analog voltage on the rotor is converted to a digital signal, which is then sent to the stator via a digital telemetry system. There are two antennas, one on the rotor that spins and one on the stator that is stationary. The stator receives the digital signal and converts it into any one of a number of usable outputs. This method of measuring torque is accurate and repeatable. However, there are limitations as to how fast the electronic parts can spin. Some bearingless torque sensors can also measure RPMs or angle of rotation with a reference pulse.

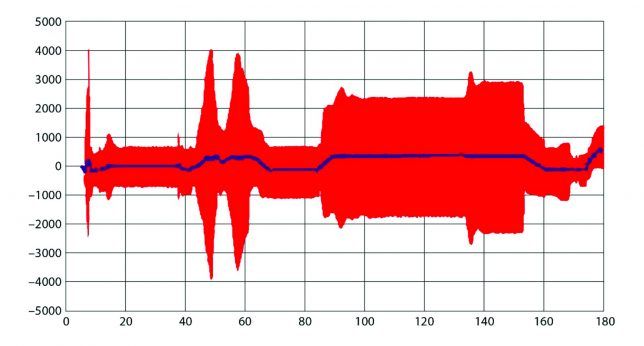

Another way of determining torque on a test stand (reaction torque method mentioned previously) is the use of a lever arm and force sensor. As Newton's third law of motion explains, for every action there is an equal and opposite reaction. If the shaft is turning clockwise, there is an equal force (reaction torque) that wants to turn counter-clockwise. Figure 2 shows the contrast between torque data acquired using a lever arm and force sensor (blue line) and the dynamic data acquired by an in-line torque sensor (red waveform). The mass of the dynamometer acts as a 20Hz low-pass filter, generating what could be called an average torque.

Figure 2. In-line torque sensors offer a more dynamic torque output than reaction torque methods (load cell and lever arm)[/caption]

Dynamic data offers engineers more in-depth information on what is actually happening with the device under test. Comparing dynamic signatures after design changes are implemented gauges their effect on product performance and efficiency. When implementing a bearingless torque sensor, especially at higher RPMs, keeping the unsupported driveline as short as possible helps reduce the risk of hitting a critical speed, i.e., the point at which a rotating shaft becomes unstable (begins to vibrate harmonically). The goal is to avoid unwanted vibrations and shaft run-out, which can increase measurement uncertainty, as well as posing the potential for a catastrophic failure of the driveline. If the driveline is short and stiff enough, there might be no need for a support bearing. Keeping most of the weight near the bearing of the power absorber reduces the sag in the driveline.

If a torsional analysis shows a critical speed still exists in the testing RPM range, a support bearing may be needed. Given that a bearingless torque sensor is unsupported in the driveline, using a dualflex- type coupling is recommended to remove any angular and parallel misalignments. It is important to remove any parasitic loads that could damage the torque sensor during use. Parasitic loads, depending on the type and size, will also add errors to the torque reading. Inserting a torque sensor directly into a driveline to capture and study dynamic data can help improve the performance and efficiency of turbomachinery. High response times make it possible to measure torsional vibrations that may lead to mechanical failures on the production floor. By eliminating parts that contribute to errors in the torque data, simplifying the driveline design can minimize test stand uncertainty. Bearingless torque sensors help to reduce data uncertainty while decreasing equipment maintenance requirements and, potentially, downtime.

Author: Mark Minda is business development manager for torque products for HBM, Inc. (Hottinger Baldwin Messtechnik GmbH). HBM’s products include sensors, transducers, strain gages, amplifiers and data acquisition systems, as well as software for structural durability investigations, tests and analysis. For more information visit www.hbm.com