VIBRATION REDUCTION: APPLYING GUIDELINES FOR AVOIDANCE OR REDUCTION OF VIBRATION IN SMALL DIAMETER PIPING

Figure: Small bore piping in the vicinity of turbomachinery can suffer from

vibration problems

Small diameter branch connections often develop vibration related fatigue failures due to mechanical excitation. Many installations do not design small diameter piping to avoid this issue. However, the risk of fatigue failure of small diameter branch connections (SBCs) can be reduced using two alternative guidelines developed by the Energy Institute (EI), and Pipeline Research Council International (PRCI)/Gas Machinery Research Council (GMRC).

Vibration of piping due to mechanical excitation is present in nearly any environment where SBCs of two inches and below are used. In initial piping designs, SBCs are often not considered or fully defined. While finite element techniques are frequently used to model the main piping system, it is time consuming and expensive to include all small bore piping.

In addition, predictions of vibration and dynamic stress and strain amplitudes made using finite element models are subject to a range of uncertainty due to assumptions that must be made regarding the excitation sources, damping, restraint stiffness values and end conditions.

There are two simpler approaches: EI’s “Guidelines for the Avoidance of Vibration Induced Fatigue and Process Pipework” and the PRCI/GMRC “Design Guideline for Small Diameter Branch Connections.” They can be used to reduce or avoid vibration problems in SBCs without requiring a detailed study.

The GMRC/PRCI guideline provides a way to estimate the mechanical natural frequency of the side branch connection to avoid a coincidence with the frequency of excitation in the main piping using a separation margin. However, it assumes that if a resonance is avoided, the likelihood of failure is low and, therefore, it does not consider fitting type, mainline risk factors, or the wall thickness of the branch or main line piping.

The EI guideline assumes the user will calculate the mechanical natural frequency of the side branch to ensure there is no coincidence. Once the user is sure that a resonance will be avoided, this guideline considers a wide range of factors to quantify the robustness of the branch design. There are two primary types of excitation in the main piping: Discrete and broadband.

Common sources of discrete excitation include mechanical excitation from reciprocating machinery, pulsation from positive displacement compressors and pumps, and vortex shedding. These sources can introduce a significant amount of energy in the system at each excitation harmonic. Broadband excitation, such as from flow turbulence in a meter station, is typically of lower amplitude but spread over a wider frequency range.

All structural systems will have multiple mechanical natural frequencies at which they will vibrate when impacted, much like a tuning fork. If the piping system is excited by a harmonic load such as pulsation or mechanical vibration at its mechanical natural frequency (resonance), vibration amplitudes will be amplified, often by a factor between 10 and 50. As high amplification occurs during resonance, the simplest solution is to avoid resonance. But in cases where mechanical resonance cannot be avoided or where excitation forces are considered excessive, detailed structural modeling should be performed.

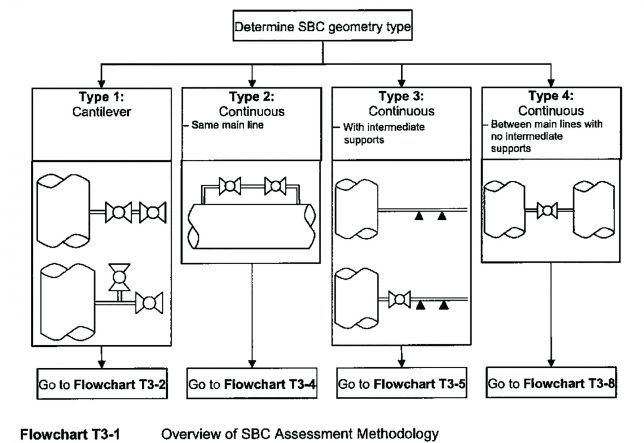

Figure 1: SBC geometry types used in the EI guideline

The EI guideline categorizes branch lines into four main categories (Figure 1): • Configuration 1 – Cantilever type

• Configuration 2 – Continuous—in and out same main line

• Configuration 3 – Continuous—with intermediate supports

• Configuration 4 – Continuous— between different main lines (with no intermediate supports)

The flowcharts in the EI guideline can be used as a broad-based screening criterion in the design phase of most SBCs to determine which are at risk of vibration. Weights are given to various characteristics to evaluate its susceptibility to vibration and fatigue.

The PRCI/GMRC guideline is a more specific guideline designed for use in evaluating SBCs at reciprocating and centrifugal compressor stations. The design philosophy for this guideline is to reduce risk by placing the lowest mechanical natural frequency of the branch connection above the frequencies of most significant excitation occurring at the base of the branch line. In addition, a secondary non-resonant stress criterion is also included to for dynamic stress (and strain) when there is significant vibration in the mainline.

This guideline provides recommendations on unsupported span lengths with and without added masses such as valves to minimize the possibility of fatigue failure. It is meant to be quick and easily used with few calculations and no special instrumentation or software. Rather than having to predict the structural natural frequency, it delineates an area on a graph showing what range of lengths and masses will raise the structural natural frequency sufficiently above the primary excitation frequencies to avoid a coincidence.

In most cases, the lowest mechanical natural frequency of the branch should be at least 20% above the first, second, or fourth multiple of the compressor running speed (guidance on frequency selection is included in the guideline). Not having to calculate the structural natural frequency is a significant advantage, especially when evaluating a large quantity of SBCs. This guideline is primarily suggested for use to screen for potential vibration problems where the mechanical natural frequency of the SBC is unknown.

A quick visual check of the appropriate graph can give the user the option to choose whether changing the length, diameter, or weight of the SBC is the best option to stay inside the limitations of the line on the graph and how much to change each factor.

For centrifugal compressors and pumps, the guideline design frequency for SBCs is 15 Hz. Mechanical natural frequencies for all SBCs should be designed to exceed 15 Hz to significantly reduce the risk of vibration from low frequency broadband excitation sources. This guideline can be extended for the use for SBCs in meter stations and other areas where flow turbulence excitation is a primary concern.

More broadly, all structural natural frequencies should be at least 10 Hz for straight horizontal spans and closer to 15Hz for all other configurations to reduce the likelihood of excitation. But use caution when installing SBCs within 25 feet of a centrifugal compressor. There is often high frequency excitation of the shell modes of the piping which can cause small bore piping connection failures.

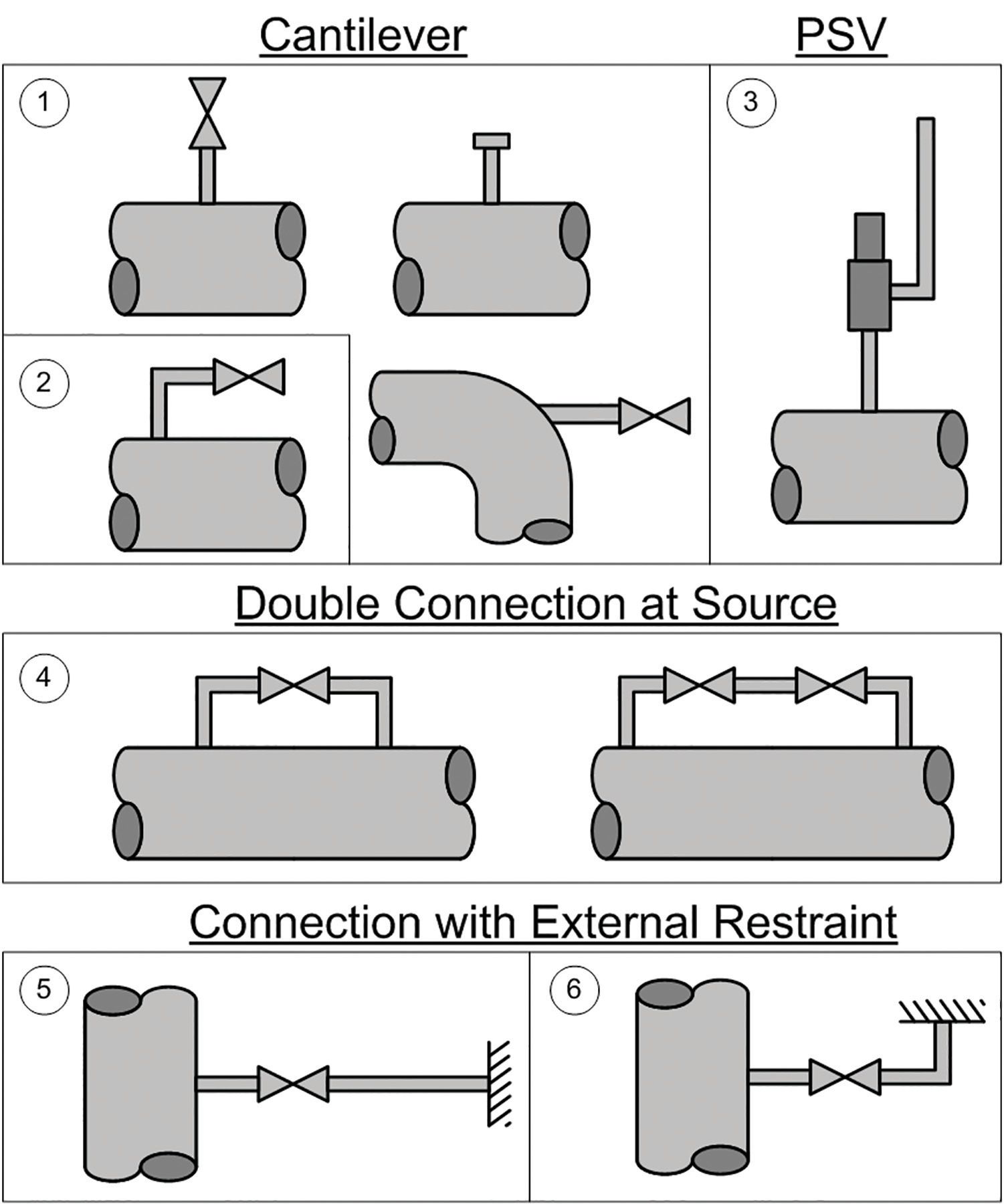

The PRCI/GMRC guideline provides recommendations for branch connections with nominal pipe diameters equal to or less than two inches, and where the nominal branch diameter to main pipe diameter ratio is less than 25%. It covers six different configurations (Figure 2).

Figure 2: Various branch connection configurations covered by the

PRCI/GMRC guideline

• Configuration 1 – Straight cantilever

• Configuration 2 – Cantilever with elbow

• Configuration 3 – Pressure safety valve (PSV)

• Configuration 4 – Double connection at source

• Configuration 5 – Straight connection with external restraint

• Configuration 6 – Connection with external restraint with elbow

Best SBC practices

Based on experience with the application of the above guidelines, the following best design practices for small bore piping are recommended. For piping design:

• Small bore piping wall thickness should be schedule 80 or higher

• Fittings with higher stress concentration factors (such as threaded connections) should be avoided in higher risk areas such as near compression equipment. Therefore, weldolets are preferable over threadolets.

• Branch line lengths should be kept as short as possible with minimal attached weight to raise the structural natural frequency

• If possible, locate the branch line away from valves, reducers, bends and tees in the main line where flow turbulence and acoustic induced vibration may cause problems

• Threaded fittings should be tight and back welded such that there are no exposed threads; threadolets are generally not recommended.

• Standard or higher schedules are recommended for main line piping to reduce the stress concentration at the connection to the SBC. Additionally, the installation of an external restraint (support, bracing, and so on ) will add stiffness to the branch line, raising its minimum mechanical natural frequency and reducing the risk of excessive vibration. As there are an almost unlimited number of potential branch line configurations, it is not possible to recommend specific restraint configurations that will cover all feasible layouts. However, the following general guidelines are provided:

• The stiffer the restraint, the more effective it will be. A minimum restraint stiffness of 10,000 lbf/in in all three translational directions is recommended.

• A good restraint should be triangulated in multiple planes to provide stiffness in multiple directions. A restraint mounted to a tall, single slender support will typically be very flexible and ineffective in controlling vibration in directions other than the axial direction of the tall support.

• Simple weight supports and springs typically provide very little vibration control.

• It is typically preferred to brace the branch line back to the mainline piping. Bracing the branch line to a very stiff external support can increase bending stresses due to relative displacement from vibration and thermal expansion. A relatively stiff external support should not be installed too close to the branch connection.

• Strap type clamps are typically more effective than U-Bolt type restraints. If UBolts are used, they should be used in pairs to prevent rotation.

• Gusset plates can add stiffness but also add high stress intensification factors and should be used with caution. If used, any gussets should attach to a reinforcing pad and not directly to the mainline. To prevent fretting, all clamps should be lined with a resilient liner material (Fabreeka or similar).

Authors: Sarah Simons is a Research Scientist in the Fluids Machinery Systems Section at Southwest Research Institute (SwRI). In this position, she has acquired extensive experience in flow and acoustic analysis, research and testing working with pipelines, industry consortiums, and DOE.

Francisco Fierro is a Research Engineer in the Fluids Machinery Systems Section at SwRI. He has extensive experience in the fields of mechanical vibrations, finite element analysis, acoustics, and compressor and piping system design.

Benjamin White leads the Fluid Machinery Systems Section at SwRI, which is responsible for the design, analysis, and field testing of a variety of gas and liquid machinery piping systems. For more information, please contact Sarah Simons at sarah.simons@swri.org or visit pulsations.swri.org