Scoping Don Bently's bearing concept

Hydrodynamic fluid film oil bearings have been standard in large equipment for over 100 years. More recently, Tilting Pad oil bearings dominate in high energy rotating equipment applications. Additionally, in the past few decades, hydrodynamic gas bearing technology has been accepted in dry gas seal applications. Foil gas bearings are also a type of hydrodynamic bearing and have seen growing acceptance in aviation HVAC, and sub megawatt micro turbines. Foil bearings are fluid film bearings supported on flexible bumps or leaves so there is low load and stiffness but large gaps and high speed capability. In contrast the bearing technology in dry gas seals often uses stiff silicon carbide and high unit loading with small gaps. All of these cases are examples of dynamic bearings; that is, fluid film bearings that generate pressure to support the load from the relative motion between the bearing surfaces. This is what our turbo industries are used to.

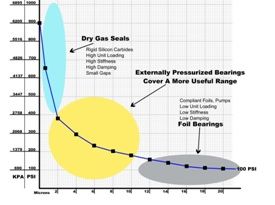

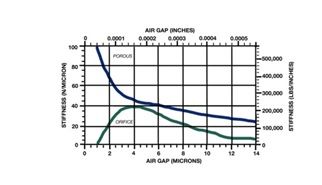

Fig.1, This is a “big picture” chart to conceptualize gas bearing technology in turbo equipment. It is a lift vs load chart for an externally pressurized porous (EPP) gas bearing that has 10 square inches of bearing face, 100 psi is fed to the bearing as the load on the bearing is increased. Resulting air gaps are shown on the bottom axis in microns. The slope of the curve is representative of the film stiffness. The typical operating regions of dry gas seals and foil bearings are superimposed as is the operating area for EPP Bearings. It can be seen that the EPP Bearings operate with a larger gap than dry gas seals, reducing heating and contact issues but still having good stiffness, damping and speed capabilities.[/caption]

What Don Bently was suggesting is the use of external pressure and compensation both to establish the fluid film and control bearing stiffness and damping, from outside the machine. After all the years of just measuring what was going on with a rotor/bearing or seal, he was demonstrating a way of tuning bearings dynamically to operating conditions in situ. Have a seal running hot? An increase of input pressure directly between the bearing faces will increase the gap proportionally, but not much is needed as shear in the gap is reduced by a cube function of the increasing gap. These are game changing ways of addressing rotor dynamic issues that have not yet been accepted by the turbo industries and this is what Don was suggesting.

Additionally, externally pressurized bearings offer new options in machine architecture. For instance, hydro and aerodynamic thrust bearings have segmented pads for the purpose of having leading edges for the fluid film wedge to develop. Because of these big radial gaps no engineer would consider a dynamic thrust bearing as a seal. Thinking alternatively, externally pressurized thrust bearings have a contiguous 360 degree face that looks just like a dry gas seal face and because the pressure is always highest in the bearing gap, it is already a seal! This gets the engineer thinking “If I could eliminate oil lubrication, combine my thrust bearing with my dry gas seal, I could even use area on the thrust runner to replace the balance piston.” This dramatically reduces moving parts and brings DGS low leakages to balance pistons (the low hanging fruit of improved compressor efficiency). The biggest advantage though, as Don would argue is that the shaft, which is the weak link, stiffens on a cube function as you make it shorter, dramatically improving the rotor dynamics.

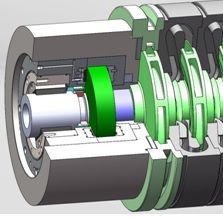

Fig 2, An externally pressurized thrust bearing looks and acts much like a double opposed face seal, when positioned on the high pressure side of a straight though centrifugal compressor, radial real estate on the thrust disc can be used as the balance piston shortening the required length of shaft enough to make a big improvement in rotor dynamics.[/caption]

Why wasn’t Don more successful with his new bearings? And what is compensation in externally pressurized bearings?

Externally pressurized gas bearings are also called aerostatic bearings, as they provide lift even at zero rpm. Although they do not have fine pumping groves like dynamic bearings, they do require some type of restriction for metering the gas into the gap. Air pressure is introduced directly between the bearing surfaces though precision holes, orifices, grooves, steps or porous compensation techniques. It is this process of restriction referred to as compensation that is key, but is not yet well appreciated.

Compensation enables bearing faces to run very close together without touching, because the closer they get together, the higher the gas pressure between them gets, repelling the faces apart. Under a flat gas bearing the average pressure in the gap will equal the total load on the bearing divided by the face area. That is the unit loading. So if the source gas pressure is 100 psi and the seal face has 10 sq. in of area and there is 600 lbs. of load, there will be an average of 60 psi in the bearing gap. Because there is a restrictor of some type just before the gap, if the load increases to 700lbs, the bearing gap reduces, chocking flow in the gap and so the restrictor can let the average pressure in the gap will increase to 70 psi.

Out of all the compensation techniques, orifice compensation is the most popular or widely used. This is also the technology Don employed. Orifice compensation typically uses precisely sized orifices that are strategically placed on the bearing face and often combined with grooves to distribute the pressurized air across the bearing face. However, if the bearing face becomes scratched across a groove or near an orifice, the volume of air that escapes through the scratch may well be more than the orifice can supply, causing the bearing faces to contact or crash. Orifice bearings also can be plagued by contamination plugging the orifice and starving the face for pressure and flow. Orifices are typically 100 to 250 µm (0.004 to 0.010 in.) in diameter and so can be readily plugged by Teflon tape or material sloughing off of the inside of the tube or some other particulate contamination.

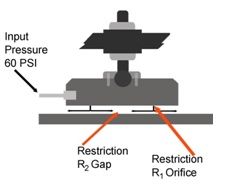

Fig 3, Orifice bearings from Bently Pressurized Bearing Company.[/caption]

Finally orifice bearings experience collapse at very small gaps. As the face of the bearing gets closer to the guide surface, the inflow around the feed hole becomes choked and is not enough to provide pressure and flow for the rest of the face. This collapse can be seen in reverse during initial lift off. By slowly increasing the supply air pressure from “0” to an orifice bearing that is grounded by a load, it can be seen that a high percentage of the supply pressure is needed before the bearing will pop up as flow is established across the face of the bearing. This is because a flat orifice bearing on flat surface has only the area of orifices and grooves to establish initial lift (Figure 4).

Figure 4: This is a cutaway side view of a typical orifice air bearing found in a coordinate measuring machine (CMM). If a pneumatic system is to be considered an "air or gas bearing," it needs to have a restriction upstream of the bearing gap restriction.[/caption]

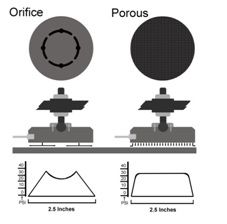

There is a more elegant method for providing this compensation. The ideal air bearing design would supply pressure equally across the whole face of the bearing and automatically restrict and dampen the flow of air to the face at the same time. This can be achieved by diffusing air through a porous bearing or seal face, we often use graphite (Figure 5). The stability of porous media compensation is due to the damping effect from the torturous passageways the gas must flow through to reach the face. This damping effect makes it difficult for the volume of air in the gap to change quickly, resulting in a naturally stable gas film that cannot be plugged by particulates. As even with the supply tubes and/or ports completely full of particulates (sand, dust, etc.), it still does not create as much restriction as the porous media itself. In the case there is contact, graphite is an excellent plain bearing material.

Figure 5: When air pressure bleeds evenly from the entire surface area of the face, the whole surface area develops pressure even when grounded. Orifice bearings have only the area of the orifices and any groves for the pressure to establish initial lift. The even pressure profile of porous gas bearings makes them more suited to heavy equipment[/caption]

Figure 6: It is well known in the dry gas seal industry that small air gaps have very high stiffness. Since flow through a gap is a cubed function of the gap, small gaps are great for reducing flows. Porous compensation in gas bearing technology has shown the best results in low fly height application.

This also works well for very small gaps and so small flows. With porous bearings, a low initial lift is achieved with a low percentage of supply pressure, and the gap increases with increasing supply pressure. This is because the whole face contributes to lift, much like the exposed area of a hydraulic cylinder, as again illustrated in Figure 5. This makes porous bearings easier to use then orifice bearings.

So a fundamental problem for Don Bently was that the Orifice compensation he was using was not as good as dynamic bearings or porous externally pressurized bearings at small gaps that become critical in upset or extreme conditions.

(Drew Devitt is chief technical officer of New Way Air Bearings that acquired Bently Pressurized Bearing Company recently)