What you need to know about gas turbine filter materials

Gas turbines are protected by air inlet filters that remove particulate contaminants to prevent blade fouling and erosion. The most common filters used today are medium grade filters, which are insufficient to capture submicron particles that cause fouling and performance loss. A newly developed filter made with hydrophobic expanded-polytetrafluoroethylene (ePTFE) membrane filter offers high efficiency particulate arrestor (HEPA) efficiency with ability to block water and salt penetration.

Below are excerpts from a paper, "Dramatic reduction of gas turbine fouling with HEPA composite membrane air intake filters" presented by Wilson Poon, Mathew Gessner and Steven Medvetz at the Turbomachinery Symposium in Texas in 2010. The multilayered media significantly improves the capture efficiency of submicron particles, without the burden of high pressure loss and short filter lifetime typically associated with high efficiency filters. A full-scale study was conducted to evaluate the performance of HEPA composite membrane filters. The new filters were installed at an oil refinery site equipped with two gas turbines from July 2008 to June 2010.

The results showed that the HEPA membrane composite filters dramatically reduced fouling and resulted in no noticeable performance loss of the gas turbine over 22.5 months. Filters returned for analysis after 11 months showed only 0.2 inwg increase in pressure loss, indicating that the filters can easily achieve two years or more service in this oil refinery environment.

FILTRATION MEDIA

There are many types of materials on the market today. The most commonly used media for gas turbine air inlet filters are cellulose, microfibers, and nanofibers. Cellulose media is the most economical, but has the lowest filtration efficiency. It is made of natural fibers (plant-based), which are coarse and nonuniform.

Microfibers are made by spunbond and meltblown processes. The polymer fibers are extruded through dies. Spunbond fibers are typically 10 to 100 m in size. The meltblown process is similar to the spunbond, but the dies have much smaller apertures and use air to “blow” the fibers to achieve smaller diameter, usually one to five microns. New technology has been developed that is capable of melt-blowing nanofibers. Furthermore, the fibers can be charged artificially to enhance electrostatic collection; therefore, offering higher efficiency at low pressure loss. However, once the charges are dissipated by loading, the efficiency of the material can degrade quickly.

Efficiency of media is related to the size of the fibers, as discussed above. Generally, the smaller the fiber, the higher the efficiency. Nano-sized fibers can be made by many means. The most common technique employed in air filtration is electrospinning. In this process, the polymer is dissolved and fed through capillary tubes under a high potential field. The resulting fibers are nanometer in size and extremely uniform. A thin layer of nanofibers can markedly increase the efficiency of the open substrate. The drawback of the technology is that the nanofibers layer is very thin, and therefore, relatively weak. It can degrade quickly in harsh and chemical environments. To achieve high filtration efficiency, a large number of nanofibers are required, but the flat morphology of the nanofibers can increase the pressure drop substantially.

Membrane media with expanded PTFE (ePTFE) have been used for many years in industrial applications such as cleanable filtration. It is made from a biaxial stretching process on PTFE tape, creating the microporous structure as shown in the picture. The fibers are connected by nodes. The three-dimensional structure of the membrane and the submicron fiber size allow it to achieve high filtration efficiency, low pressure loss, and relatively high strength. Still, in most cases, the membrane has to be bonded to support substrate in order to be made into final products. PTFE material has high hydrophobicity. Combined with microporous structure, ePTFE membrane can resist penetration of water, while allowing air to pass through.

The generic cellulose, meltblown, electrospun nanofibers are compared to the composite membrane media as shown in Figure 2. The cellulose has large irregular fiber diameter. The meltblown has open structure with fibers from 1 to 10 micrometers. The electrospun nanofibers media has a thin layer of nanofibers on the surface of the substrate. Because the layer is so thin, it is relatively open and the cellulose fibers behind are clearly visible. The ePTFE membrane has a continuous web of interconnected fibrils that are less than one micrometer. The microporous membrane is relatively thick (75 micrometer) compared to the electrospun nanofibers.

COMPOSITE MEMBRANE FILTERS

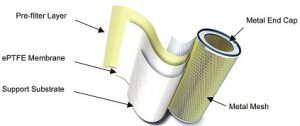

Expanded View of E12 Pleated Filter with Composite Membrane Media.[/caption]

To address the needs of better performance for gas turbine inlet filtration, a new filtration technology was developed based on composite membrane.The key to the invention is a multilayer media that combines microporous membrane (Figure 2) with a prefiltration layer in a proprietary bonding process. The hydrophobic PTFE membrane is air permeable, but highly resistance to liquid water. The media is pleated to form a cartridge filter that can withstand extreme environmental conditions in the field and the potential burst pressure due to gas turbine upset. An expanded view of the filter construction is shown in the figure.

Most of today’s filters do not stop water from passing through the filters. Filters can become wet due to high humidity, heavy rain, or mist from nearby cooling towers. When this occurs, the soluble particles collected on filters can dissolve in water and migrate downstream. Over time, enough salt crystals can build up and then shed off from the filter. Salt can contribute to hot corrosion in gas turbines and cause long-term reliability issues. The hydrophobicity and microporous structure of ePTFE provides a natural barrier to liquid water and dissolved salts.