FS-Elliott Unveils Oil-Free, Aerodynamic Centrifugal Compressor

The P650 features a removable air-end design and horizontally split air-end components to allow for undisturbed inspection and maintenance.

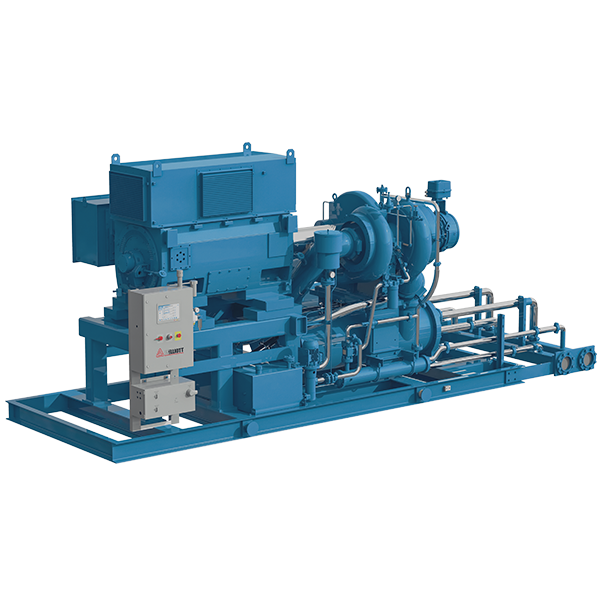

FS-Elliott, as part of its Polaris portfolio, launched the P650 centrifugal compressor that offers ISO 8573-1 Class 0, oil-free air to optimize performance and efficiency. The P650’s aerodynamic design reduces energy costs and carbon footprint and features a Regulus control system and a large color touchscreen to simplify operation.

“The P650 is designed to deliver reliable, efficient compressed air to customers so they can focus on maximizing their productivity,” says Michael Wik, Director of Product Management at FS-Elliott. “The P650 features aerodynamic performance, reliability, and ease of maintenance, resulting in providing the lowest cost of ownership for compressed air.”

Reliability & Efficiency

Aerodynamics boost high-stage efficiency across turndown ranges and supports heat-of-compression drying technology to promote energy savings; also, advanced centrifugal controls deliver maximum energy savings. In terms of reliability, all Polaris compressors have a 2-year full package warranty and FS-Elliott’s SteadAir 5-year air-end warranty. These warranties protect critical machinery in production facilities and across difficult applications in challenging environments.

P650 centrifugal compressor; image credit: FS-Elliott

Operation & Maintenance

The P650 features a removable air-end design and horizontally split air-end components to simplify field replacements and enable inspection and maintenance without disrupting air piping. The large color human-machine interface and suite of control options allow customers to easily use the P650 centrifugal compressor.

FS-Elliott News

In August 2024, FS-Elliott launched its new programmable logic controller for centrifugal compressor applications—the R3000 control panel. The configurable design enables reliability, energy efficiency, and advanced customization via advanced compressor diagnostics with onboard historical data tracking. Leveraging data-logging capability, users can quickly obtain factory-direct engineering assistance.

FS-Elliott also equipped the R3000 control panel with remote monitoring capabilities: an optional FS-Connect system offers a comprehensive data dashboard and customized reports to further enhance efficient, reliable operation. FS-Elliott Channel Partners will receive notifications when service is needed, which minimizes unnecessary or unscheduled downtime.

The R3000 uses FS-Elliott’s Energy Advisor and Maintenance Notification system to ensure compressor operation at optimal efficiency and reliability.

Energy Advisor: Continuously monitors operational efficiency and enables improvement via automated, actionable suggestions.

Maintenance Notification: Tracks the usage of maintenance parts and alerts users when predictive maintenance (PdM) is required. As a byproduct, PdM alerts reduce energy consumption and CO2 emissions.