GE introduces gas turbine-powered LNG ship

The concept of using a combined gas turbine and steam (COGES) plant for merchant vessels, and LNG carriers in particular, was first announced by GE at The Motorship’s 2013 Gas Fuelled Ships conference and featured in our December issue. The concept is claimed to offer low life cycle cost, high environmental performance and flexible design.

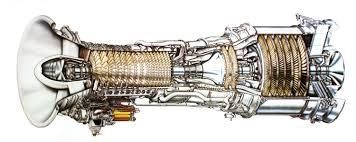

The initial LNG carrier design will be built around a GE system that will feature one LM2500 25MW gas turbine, one steam turbine generator-set and two dual-fuel diesel generator-sets for low power operation and backup. However, the carrier will allow for flexible configuration of prime movers, offering a total installed power of more than 50 MW, if required. The GE gas turbines can be equipped with a GE Dry Low Emissions (DLE) or single annular combustion system - both capable of meeting IMO Tier III IMO and US EPA Tier 4 requirements with no exhaust treatment and no methane slip.

“Trends indicate more LNG carriers will be needed to meet growing global demand. China will also require more and more LNG carriers over the next 10 years to meet the country’s growing energy needs,” said Yu Fengping, president of DSIC.

According to Nicholas Brown, Lloyd’s Register, the company recently spearheaded and completed a preliminary hazard identification (HAZID) study, the first in a series of studies to be performed on the COGES LNG carrier. “This study delved into the carrier’s hazardous areas, structural integrity, safe separation, pipe routing and ventilation. The studies will help mature the design and minimize risk for the COGES LNG carrier system,” he said. Lloyd’s Register will contribute a series of risk assessment studies during the design development leading to a safety case document that meets, or exceeds, the most onerous bidding qualification requirements of oil majors for new technologies for LNG shipping.