MAN Energy Supplies Integrally Geared Compressors for Tangguh LNG Plant

The supply scope for bp’s enhanced gas recovery and carbon-capture project includes three integrally geared CO2 compressors equipped with an electric motor and variable frequency drive starter.

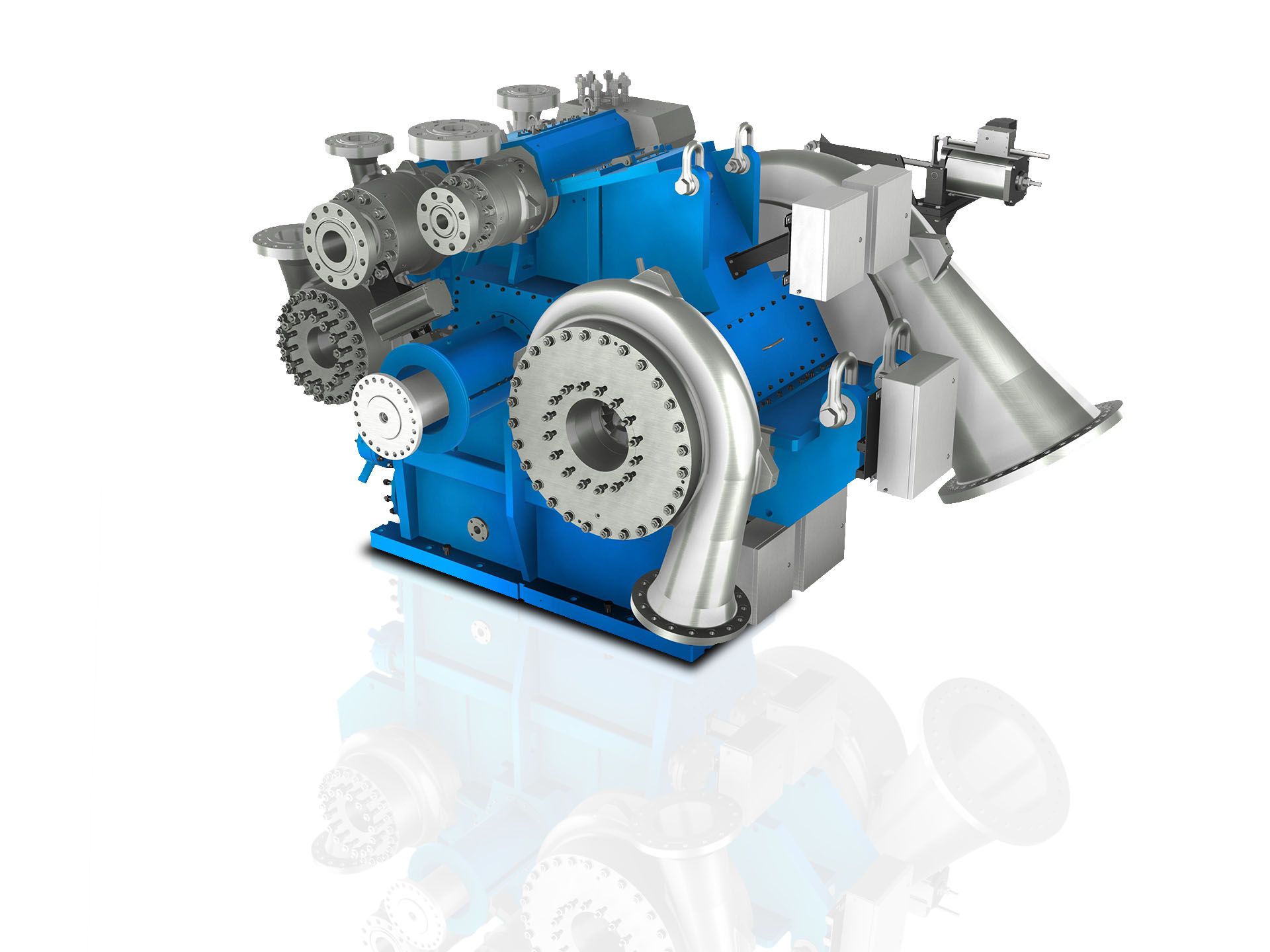

MAN Energy Solutions will deliver three multi-shaft, type RG90-8 integrally geared CO2 compressors to the Tangguh LNG plant in Papua Barat, Indonesia, assisting bp’s enhanced gas recovery (EGR) and carbon capture, utilization, and storage (CCUS) project. The compressor trains will be installed at an onshore facility to compress CO2 to a 165-bar maximum.

“We are delighted to collaborate with bp on this project that supports Indonesia in meeting its carbon reduction targets and advancing its energy transition goals,” said Dr. Marco Ernst, Head of Sales and Project Management CCS at MAN Energy Solutions. “CO2 emissions remain a challenge in LNG production, making CCUS solutions an essential part of the transition to a more sustainable energy future. With our compressor technology, we draw on our know-how and years of experience in CO2 compression to provide efficient and reliable solutions tailored to the demands of projects like this one."

Supply Scope

Each compressor will feature an electric motor and variable frequency drive starter, oil system, coolers, and control cabinet, with MAN Energy’s dynamic process simulation enabling each compressor to operate at maximum process efficiency. The modular compressor design is specifically tailored to CCUS applications, meeting market and environmental demands.

RG90-8 integrally geared compressor; image credit: MAN Energy Solutions

“Pre-designed compressor modules allow us to adapt our engineering more quickly and effectively to the specific project needs,” said Lars Rosenow, Project Manager Sales at MAN Energy Solutions. “This modular approach not only helps reduce CAPEX and OPEX but also ensures high operational efficiency. Additionally, it simplifies project implementation by reducing production and testing times and streamlining on-site installation.”

Project UCC

The compressor supply falls under Tangguh’s Project UCC, which aims to develop the Ubadari gas field by extending the gas feed to its three-train LNG operations. The project is expected to separate reservoir CO2 from produced gas and reinject it for bp’s EGR and sequestration work.

MAN Energy News

This week, MAN Energy Solutions and Vicinity Energy agreed to develop a pump project to accelerate Boston’s urban decarbonization, which builds upon 2023’s plan to supply a low-temperature heat source to generate steam for district energy applications. MAN Energy will deliver a 35-MW industrial-scale steam heat pump for installation at Vicinity’s Kendall Station in Cambridge, MA, utilizing climate-neutral thermal energy from the Charles River.

The system will produce high-pressure, low-carbon steam—otherwise known as eSteam—to customers on Boston’s district energy network, while replacing fossil fuel-based systems on the grid. Serving as a potential model for large-scale urban decarbonization, the river-source heat pump complex is slated to become the largest installation of its kind in the United States by 2028.

In September 2024, the Canadian Coastguard, as part of a consortium with GE Power Conversion, ordered propulsion systems from MAN Energy Solutions for two Arctic offshore patrol ships (AOPS). MAN Energy will deliver the engines, shafts, and propellers for the AOPS’ integrated diesel-electric propulsion systems, as well as integrated logistics services documentation. The company will also provide a selective catalytic reduction system with each engine.

Each vessel will feature four MAN 6L32/44CR engines—each delivering 3,600 kW—and will utilize common-rail electronic injection, high-efficiency turbochargers, electronic hardware, and variable valve timing. Irving Shipbuilding will construct the vessels in Halifax, Canada, with MAN Canada PrimeServ organizations providing service support to the Canadian Coastguard to use the AOPS throughout their operational life.