Vendor Spotlight: Kobe Steel

Centrifugal, Screw and Reciprocating Compressors for Various Operating Conditions

Kobe Steel, also known as Kobelco, manufactures centrifugal, screw and reciprocating compressors. It supplies rotating machinery that serves a wide range of industries and operating conditions. This includes: integrally geared centrifugal compressors for high-pressure applications and large ones for air services; large dry screw compressors and screw compressors for LNG carriers; and reciprocating compressors for LNG carriers.

Figure 1: Main air compressor for an air separation plant.[/caption]

Integrally geared compressors

In recent years, the demand for compressors with greater capacities has been increasing as plants become larger. Kobelco’s integrally geared centrifugal compressors (IGC) cover various applications where large capacities are needed. Typical examples are air separation plants and high-pressure applications such as carbon capture and storage (CCS). Integrally geared centrifugal compressors are gaining in popularity due to their energy-saving features.

The main air compressors used for air separation applications (Figure 1) account for much of the total power used in a plant. As a result, IGCs are increasingly being used for these applications. Recently, the size of plants has increased to improve operational efficiency. Larger IGCs are required with high flow coefficient impellers offering high reliability. In terms of mechanical reliability, it is important to evaluate blade strength against the centrifugal force and the external excitation force when using unshrouded impellers due to the height of the blades.

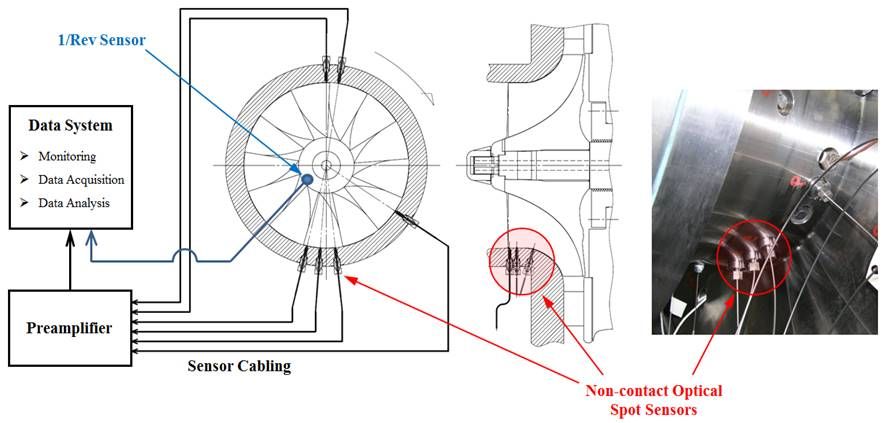

Large impellers with a high blade height are used for large capacity applications, where vibratory stress of the blades must be correctly assessed and verified (Figure 2). Measurement results reveal that the actual vibratory stress in the various operating points, including the blade resonance and the surge, are at sufficiently low levels when considering the material strength. This confirmed its ability to deal with such stress.

Figure 2: Kobelco established an evaluation method for dynamic blade stress using optical spot sensors for non-contact blade vibration measurement of the compressor.[/caption]

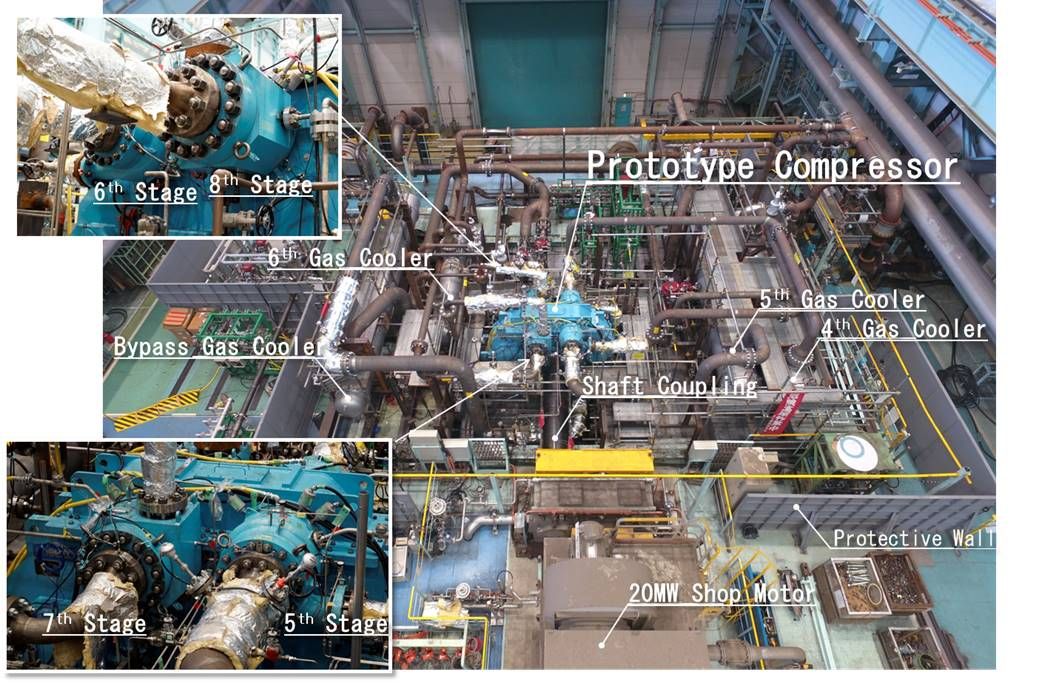

An integrally geared CO2 centrifugal compressor (2,900 psiG/20 MPaG discharge pressure level) was designed, manufactured and evaluated for fluid dynamic performance and rotor stability. Full-load and full-pressure tests were carried out using real CO2 gas (Figure 3). Compressor fluid dynamic performance was excellent even at high pressure supercritical gas conditions at the high-pressure stages of the compressor. Rotor vibration remained low even at high pressure.

Further tests were conducted. The direct rotor excitation method experimentally investigates rotor stability. With this technique, measurement of actual rotor natural frequencies and the damping ratios (log decrement) during high pressure operating conditions provided more precise results than the conventional casing excitation method.

These results clarified that measured natural frequencies agreed with calculations. Also, the measured damping ratios of the rotor forward modes were higher than the calculated values. The effects of increasing damping methods using squeeze film damper bearings were also investigated during this test. Fluid dynamic characteristics and mechanical reliability were assessed as acceptable including the supercritical gas condition of CO2 gas. Conclusion: The improved reliability and efficiency of IGCs make them an attractive choice for high-pressure and air service applications. And with these compressors saving on space and energy, adoption is increasing.

Figure 3: Overview of the prototype high-pressure CO2 compressor and test facility.[/caption]

Screw compressors

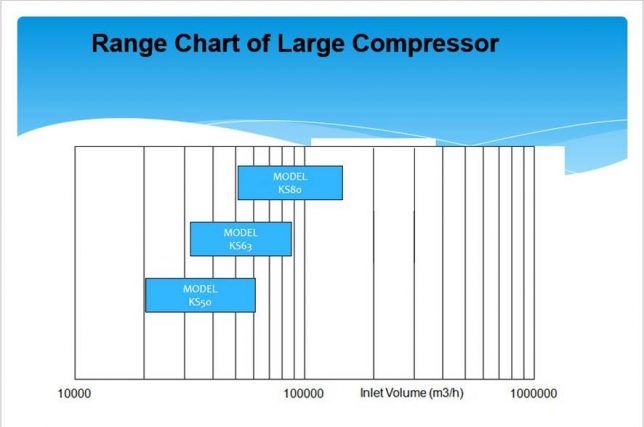

Large-capacity, oil-free screw compressors are widely used in the petrochemical, petroleum refining and gas processing industries. The most popular application for these compressors is in the styrene monomer process in petrochemical plants. Since this application needs high capacity, Model KS63 (rotor diameter of approximately 63 cm) is often adopted.

In response to market demands for even larger machines, Model KS80 (rotor about 80 cm) was developed (Figure 4). Since the rotor is heavy, the casing is split horizontally to provide easy maintenance. Water injection to the compression chamber controls discharge temperature. The rotor and casing are stainless steel.

Figure 4: Kobelco compressor unit Model KS80[/caption]

To increase capacity, compressor speed is increased. With higher compressor speeds, however, the pulsation level at the discharge side is higher. To reduce pulsation and decrease acoustic energy inside the discharge piping, discharge silencers are usually provided on the suction and discharge nozzles. The pulsation level and its frequency depend on various parameters such as gas composition, pressure, and temperature. Model KS80 compressors can be equipped with silencers designed to meet a variety of requirements.

Figure 5: Kobelco screw compressor unit for the X-DF engine application[/caption]

LNG compressors

Reciprocating and screw compressors are often specified for LNG carriers. Shipping firms facing tightening environmental regulations gravitate to low-speed dual-fuel engines such as the ME-GI and X-DF (Figures 5 & 6).

In the ME-GI system, boil off gas (BOG) of 3.0 – 5.0 t/h generated from the LNG tank is boosted by reciprocating compressors at atmospheric pressure to 30 MPa. It is then supplied to the ME-GI engine for propulsion of LNG carriers. Surplus gas from the intermediate stage (15 MPa) goes to the re-liquefaction system.

Figure 6: Kobelco reciprocating compressor unit for ME-GI engine application[/caption]

In the X-DF system, BOG generated in the LNG tank is boosted to about 1.5 MPa by a screw compressor. Surplus gas is boosted to 15 MPa by a reciprocating compressor and supplied to the re-liquefaction system. These compressors often include a combined fuel gas control/management system to optimize fuel gas supply to the X-DF engine and re-liquefaction gas to the LNG tank.

Taking into consideration the need for compressors mounted in LNG carriers, a vertical compressor has been developed that is suitable for installation in the limited space on ships. It saves space compared with horizontal compressors.

A re-liquefaction system liquefies excess gas. However, oil contained in the gas can condense inside the heat exchanger in the cooling process, causing a decrease in efficiency. To resolve this issue, a piston ring capable of boosting the pressure to 15 MPa without lubrication was developed. A 30 MPa non-lubricated piston ring has also been completed and will undergo trials. ■