Digital Twins

A simulated product model can visualize exactly when and where maintenance is needed, instead of making blind guesses and safe bets.

BY SAMEER KHER

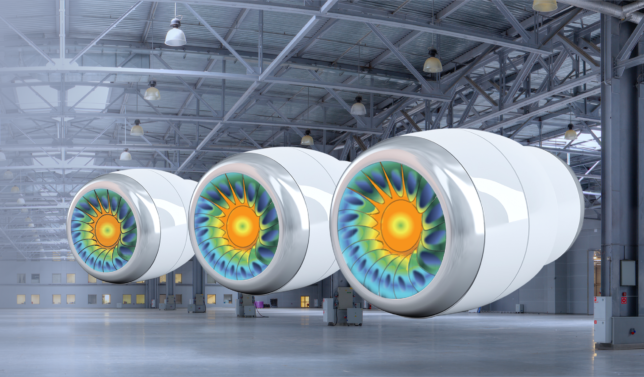

A rendering of digital twins for jet engines

One of the newest frontiers in simulation is the concept of the digital twin. By using product-mounted or virtual sensors, companies can collect operating data from the field in real time and use that information to create an exact replica of the working product in a controlled virtual space. By studying how the simulated product model performs under real-world conditions, companies can flag performance issues, schedule predictive maintenance, reduce downtime and minimize warranty expenses. This is an attractive proposition. Yet many businesses have faced challenges in implementation due to the specialized expertise and cross-functional partner-ships required.

Modeling

For decades, engineers have leveraged simulation to develop products in a virtual design space. By applying a range of physical forces and operating parameters to three-dimensional designs, engineers have been able to launch products with confidence they will perform as expected under real-world conditions.

Once a visionary idea, simulation-driven product development is a best practice applied by all types of companies, saving time and money.What has been missing, though, is a closed-loop approach that ensures simulation remains a competitive advantage once products are launched into the field. The digital twin adds the ability to monitor product performance over time, empowered by advances in digital technology.

A digital twin is a simulated model of an actual working product in the field. It is informed by sensors that gather and feed-back real-time, real-world operating data. By studying the digital twin, companies can see how the product performs over time in the physical environment. This enables a product development team to close the loop on initial simulations. Engineers can make more informed choices for future designs and make simulations even more accurate.

More importantly, digital twins make the dream of true predictive maintenance possible. Instead of over-servicing or over-maintaining turbomachinery to perform repairs, replace components and avoid downtime, companies can act “just in time” to address any performance issues. They can visualize exactly when and where maintenance is needed, instead of making blind guesses and safe bets.

The time and cost savings are substantial. Connected product technology allows durable, competitively priced sensors to be mounted on working products to sup-ply data to digital twins cost effectively.

Practical challenges

Digital twins of turbomachinery, however, remain largely the province of a few companies due to a lack of dedicated resources. Specialists are needed to create a simulated product model, verify the model, connect it to actual working products and then analyze the collected information. As this process involves multiple functions and technology platforms, practical challenges inhibit implementation. An easy-to-implement simulation solution is needed to realize the potential of digital twins.

Such technology is now available. It consists of a platform that can be integrated across business functions to place digital twins within reach of more companies. Leveraging the concept of digital twins involves three steps:

• Building a digital model of the product system

• Verifying the model

• Implementing it by connecting it to the physical product in the field.

Those harnessing engineering simulation to design products have already accomplished the first two steps. Engineers supporting the digital twin initiative would build a three-dimensional product model and verify and optimize its performance by applying multiple physical forces that replicate the real world in which the product operates. Models and data from the original product development process can be reused to save time and money.

Twin Builder helps turbomachinery operators create and operate digital twins. Courtesy of ANSYS

Solutions exist that integrate with smart sensors mounted on equipment, as well as third-party technology systems and tools. Data captured by sensors continuously update the model as time passes and conditions change. Insights gained from the digital twin inform future product development efforts, while helping operations personnel optimize lifetime maintenance and repairs.

The digital twin opens the door to actual predictive maintenance that can analyze the physical effects of vibration, wear and other stresses. Maintenance managers can visualize and study exactly what is happening inside critical systems via a three-dimensional virtual model that is subjected to the same environmental conditions as the working product.

Sameer Kher is Twin Builder Product Line Director in the Systems Business Unit of ANSYS. The ANSYS Twin Builder platform provides an easy way for turbomachinery opera-tors to implement the digital twin. For more information, visit ansys.com