DUAL DRIVE COMPRESSORS

THE CASE FOR HYBRID DRIVE COMPRESSION TRAINS

Oil & gas companies are under intense pressure to decarbonize and lead the energy transition while meeting production goals. For many assets including pipeline compression stations, gas and LNG plants, and production sites, generating the horsepower required for compression can be a significant contributor to both facility emissions and OPEX.

Selecting the type of machine to perform this duty has historically been a binary decision for operators – with most opting for either an electric motor or mechanical drive solution, such as a gas turbine or reciprocating engine. However, a strong business case can be made for combining one or more mechanical drive components with an electric motor (or motor-generator) into a single hybrid/dual drive train. These configurations can offer advantages over single-drive systems including flexibility, efficiency, lower costs, and a reduced carbon footprint.

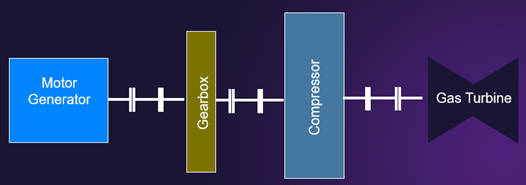

Figure 1: Simplified layout for a hybrid/dual drive train.

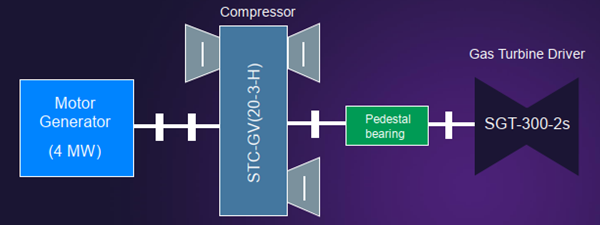

Figure 2: LNG dual drive layout.

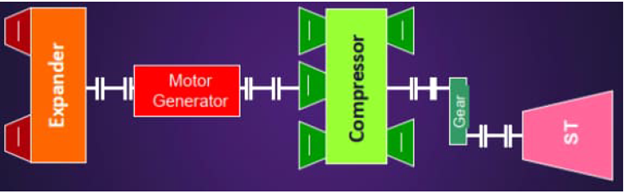

Figure 3: Typical PTA Train Arrangement

HYBRID DRIVES

Many facilities, particularly pipeline compression stations, already feature both electric motor and gas turbine-driven trains. By using different drivers, operators can avoid being locked into a singular energy supply. Operating two trains means at least partial station operation if or when one needs to be shut down for maintenance. However, having separate trains does not always constitute the most efficient equipment arrangement, as one train might be sitting idle for much of the year.

A hybrid/dual drive may be a better option in certain circumstances by affording operators the same flexibility to use available gas or grid electricity as their energy source but without the complexity of installing two trains. This lowers CAPEX as ancillary infrastructure is greatly reduced such as foundations, piping, wiring, cabling, electrical systems, and Balance of Plant (BoP).

Example: Electric motor-driven (EMD) compression is being viewed as one facet of decarbonization. On grids with a high percentage of wind and solar, an operator can use an EMD to run compressors during off-peak hours when prices are low and grid stability is high. The gas turbine would only be started up when electrical power is not available or prices were high.

As the motor can be designed to dually work as a generator, it also becomes possible to use any extra power from the turbine to produce electricity for site duty. The additional electricity can potentially be sold back to the grid. Grid connectivity, too, requires constant gas turbine speed. This can be achieved with advanced electronics. Similar flexibility is also provided by using variable inlet guide vanes (VIGVs).

Another scenario where a hybrid drive can be beneficial is at sites with gas turbine-driven compression trains that experience large temperature fluctuations due to seasonality. Available power from gas turbines decreases as the ambient temperature increases. As a result, units are often oversized to ensure sufficient power during the hot summer months. However, the same gas turbine may generate much more power during the winter than the compression train requires. This results in low-load operation of the gas turbine, reduced efficiency, and increased emissions.

Opting for a hybrid drive by installing an electric motor on the shaft end of the compressor opposite the gas turbine can solve this problem (assuming a grid connection is available). In such cases, a smaller turbine can be selected to operate fully loaded. The motor or motor-generator supplies any additional horse-power required when the temperature rises above design point. If the turbine produces more horsepower than is required for the compression duty in colder months, the motor-generator can be used to produce additional electricity, which can be used at the site or sold to the grid. By running the gas turbine at an optimal load, NO and CO emissions are reduced. Fuel consumption and associated CO₂ emissions are also decreased.

TRAIN ARRANGEMENT

Depending on the application and specific type of equipment used, multiple dual drive configurations are possible. In the case of centrifugal or integrally geared compressors with two shaft ends available, a typical arrangement would involve installing an electric motor or motor-generator on one side of the compressor shaft end and the gas turbine on the other. The need for clutches and gearboxes will be determined by the type of motor used and operation of the compression train.

For centrifugal compressors, a typical train configuration would comprise a gas turbine with a clutch on one side and an electric motor with a speed increasing gearbox and a clutch on the other side. With such a setup, the electric motor could be used as the primary driver (the gas turbine as backup) when electricity is available from the grid. Switching between the motor and the gas turbine is possible via engagement and disengagement of the clutches, with minimal disruption to pipeline operation.

For axial inlet compressors, which only have one end for connecting a driver, the motor will have to be installed between the gas turbine and the compressor. The motor acts as a part of the shaft which transmits power from the gas turbine to the compressor. In gas turbine drive mode, the circuit breaker is open and the motor continues to spin without a load.

REAL WORLD EXAMPLES

A utility-scale LNG liquefaction plant in the Northeast United States is being built. It features a gas/electric drive system. It combines a Siemens Energy SGT-300 gas turbine (8 MW), STC-GV integrally geared compressor, and electric motor-generator to ensure stable and efficient operation of the refrigeration/liquefaction train. The compressor is pinion-driven from the gas turbine side and bull gear-driven from the motor-generator side with no need for clutches or a separate gearbox. A single lube oil system supplies oil for the entire train.

During cold months, the gas turbine drives the N₂ refrigeration compressor and the generator, supplying about 3 MW of additional self-generated power to meet the plant’s electrical demand. This reduces the need to purchase power from the grid. When turbine output decreases during summer, the motor-generator acts as a motor to supply additional power to the compression system. After start-up, the facility is expected to produce a baseload of 170,000 gallons of LNG per day and up to as much as 250,000 gallons without shutting down.

The hybrid drive concept has also garnered attention in the downstream sector. In refineries, the Purified Terephthalic Acid (PTA) process is exothermic (releases heat). It normally includes a steam turbine, one or two hot gas expanders, and a motor/generator to export power. The motor/generator starts the process by driving the train to produce air. Once the process is producing steam and off gas, the motor generator is used to export power to the grid. The train is not stopped.

Operators can’t afford a shutdown due to grid instability or lack of available power. Supplementing an electric motor-generator with a gas turbine (or vice versa) in a dual/ hybrid train provides added assurance.

Gautam Chhibber leads the Proposals team at Siemens Energy. He is responsible for delivering market-specific solutions to meet energy market challenges. For more information, visit siemensenergy.com