SUPERCRITICAL CO2

10 MW DEMONSTRATION PROJECT UNDER CONSTRUCTION

Assembly of supercritical carbon dioxide pilot showing welding of the piping network in progress in the STEP 10 MWe facility

Supercritical carbon dioxide (sCO₂) power cycles are Brayton cycles that utilize sCO₂ working fluid to convert heat to power. They offer the potential for higher system efficiencies than are possible with other energy conversion technologies such as steam Rankine or Organic Rankine cycles; especially when operating at elevated temperatures. sCO₂ power cycles are being considered for a wide range of applications including fuel-fired systems, waste heat recovery, concentrated solar power, nuclear power generation, and energy storage.

The unique properties of sCO₂ offer benefits over steam as a working fluid in closed and semi-closed cycles to absorb thermal energy, to be compressed, and to impart momentum to a turbine. The supercritical state of CO₂ – nominally above 31℃ (88℉) and 7.4 MPa (1070 psia) – is easily achieved.

Above these conditions is a supercritical fluid with compressibility but with higher density compared to steam or air. This results in much smaller turbomachinery (a factor of 10:1) for a given power level.

Given these attributes, sCO₂ power cycles can offer several potential benefits:

- Higher cycle efficiencies due to the unique fluid and thermodynamic properties of sCO₂

- Reduced emissions resulting from lower fuel usage

- Compact turbomachinery resulting in lower cost, reduced plant size and footprint, and more rapid response to load transients

- Reduced water usage, including water-free capability in dry-cooling applications in applicable site conditions

- Heat source flexibility applicable to zero and low emissions heat sources.

To facilitate the development and commercial deployment of the indirect sCO₂ cycle at elevated turbine inlet temperatures, pilot-scale testing is required to validate both component and system performance under realistic conditions at sufficient scale.

Accordingly, GTI Energy, Southwest Research Institute (SwRI), and General Electric Global Research are executing the Supercritical Transformational Electric Power (STEP) Demo project to design, construct, commission, and operate an integrated and reconfigurable 10 MWe supercritical CO₂, (sCO₂) pilot plant test facility.

The project is funded partially by the US DOE’s National Energy Technology Laboratory (NETL) as well as team members, component suppliers, and Joint Industry Program (JIP) members. The facility is located at SwRI’s San Antonio, Texas, USA campus. Its goal is to facilitate sCO₂ cycle-based power generation commercialization. With the design phase complete, Phase 2 is now well underway in a dedicated 22,000 ft² building.

There are several objectives in mind for this ambitious project. As well as demonstration of the operability of the sCO₂ power cycle, researchers want to verify component performance, and demonstrate the potential for producing a lower cost of electricity, a thermodynamic cycle efficiency of greater than 50%, and a ≥ 700℃ turbine inlet temperature. Additionally, they plan to validate a recompression closed Brayton cycle (RCBC) configuration.

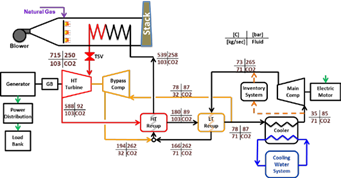

A couple of different configurations will undergo testing. The initial system configuration will be the sCO₂ simple cycle operated at turbine inlet temperature of 500℃ and pressure of 250 bar. It comprises a single compressor, turbine, recuperator, and cooler. This configuration offers the shortest time and lowest risk to obtain steady-state and transient data. It is particularly relevant to waste heat recovery applications from small simple cycle gas turbines. An RCBC configuration, operating at 715℃ and 250 bar, will follow to demonstrate the highest efficiency potentially achievable within the limits of state-of-the-art known and approved materials.

RCBCconfiguration has the potential to deliver greater than 50% thermodynamic cycle efficiency at commercial scale

COMPONENT AND MANUFACTURING INNOVATION

Plenty of work has gone in to ensuring the various components are fit for purpose. Here are a few examples:

The 10 MW turbine has been tested in a predecessor project at 1 MW to 715℃ and 27,000 rpm. Improvements for 10 MWe testing include increased rotor life (100,000 hours), shear ring retention rather than bolts, couplings on both shaft ends, and improved aerodynamic performance with an optimized volute flow area.

Control of the flow to the turbine and shut off in an emergency situation requires a special control valve adapted from a GE Power commercial steam turbine to accommodate sCO₂ fluid and the operating temperatures. When needed for an emergency shutdown, it will close in under two tenths of a second. It uses Haynes 282 high temperature nickel alloy material, advanced stem sealing, and compact self-contained actuators leveraged from commercial designs used by Baker Hughes.

The compressors leverage an existing commercial Baker Hughes product line as well as work undertaken by GE and SwRI in the DOE-funded APOLLO program. The compressor rotors are a monolithic design for the reduced size impellers inherent in this compact sCO₂ power cycle. Like the monolithic turbine, these have been 5-axis EDM machined by Baker Hughes in its shops in Florence, Italy.

Various operating scenarios have been addressed, including low-speed start of the compressor under liquid or two-phase conditions. During a pressurized hold, the sCO₂ loop will cool to ambient temperatures and liquid CO₂ formation is likely. Restart with liquid or two-phase CO₂ is required to avoid loop blowdown and control flexibility is a requirement with special care and monitoring to warm up under low load and avoid potential equipment damage.

STEP systems engineer, Dr. Scott Macadam of GTI Energy, holding the full scale model of the STEP Demo turbine rotor in front of the new STEP facility.

Component commissioning of the system is ongoing with plans to complete plant construction in early 2023. The team expects to complete the initial phase of testing later in 2023 with publication of results and findings to follow.

John Marion, Senior Director Programs, Energy Supply & Conversion at GTI Energy, Des Plaines, IL, USA. GTI Energy is focused on developing, scaling, and deploying energy transition solutions that improve lives, economies, and the environment. To receive a copy of the ASME paper which gives more details of the test set up and components, contact JMarion@gti.energy