How to mitigate failure mechanisms caused by residual stresses

When failures occur in turbomachinery, they typically result from one or more mechanisms,which may include fatigue, environmentally assisted or stress corrosion cracking, creep rupture, erosion, foreign object damage, and others. In many cases, the residual stress levels present in the component play an important role in the life realized in service, either extending life with favorable residual stresses or diminishing it with unfavorable ones. Since residual stresses are introduced in practically every step of the machining and fabrication processes of turbomachinery components, their effects must be considered, understood, and managed so as to maximize component life and performance. By controlling or introducing engineered residual stresses, premature failures can often be mitigated and the service life of components extended. Accurate quantitative measurement of residual stress in turbomachinery components is necessary to achieve this goal.

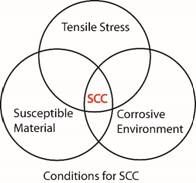

Figure 1: Synergy required for SCC to occur[/caption]

Stress corrosion cracking (SCC), also known as environmentally assisted cracking and sometimes characterized as stress-assisted grain-boundary oxidization (SAGBO) in high-temperature applications, is a major source of potential failures in the power industry, as well as in process industries, pulp mills, storage vessels, and even aircraft structures. Sustained tensile stress (resulting from the superposition of residual and applied stresses) above the material’s SCC threshold is the main component of the stress corrosion cracking triangle (see Figure 1); the other two are a susceptible material and an environment that often needs to be only slightly corrosive to that material. SCC is characterized by selective intergranular corrosion whereby multiple cracks initiate and eventually propagate.

There are several possible solutions to the SCC problem. The first and most obvious solution is to change the environment, but that is rarely possible. The addition of a coating can, in principle, break the SCC synergy by sequestering the material from its environment, but this is often impractical or only a short-term solution if the coating wears or degrades over time. Another obvious solution is to change the material to one less susceptible to SCC, but that can be very expensive or unfeasible. Thermal stress relief can be used to help reduce the magnitude of tensile residual stresses to levels below the SCC threshold; however, if the heating reaches the annealing temperature, as would be required to effectively stress relieve the component, the heat treatment itself may negatively affect the desired material’s mechanical properties.Heat treatment is, therefore, only a partial solution in many instances. Corrosion engineers have long recognized that in many instances, the only effective solution to the SCC problem is the introduction of compressive residual stresses.

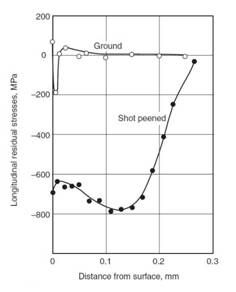

Figure 2: Residual stress vs. depth profiles for ground and shot-peened Ck45 steel[/caption]

A wide variety of stress management methodologies can be used to impart compressive residual stresses into a component, including peening, rolling, expanding, and their variants. Some of these variants are typically applied at the time of fabrication (e.g., shot peening, laser shock peening(LSP), cavitation peening, rolling, etc.), whereas others can be applied in the field on components already in service (e.g., ultrasonic impact treatment (UIT), flapper peening, split-sleeve cold expansion (Cx), etc.). If the compressive residual stresses imparted are sufficiently great to overcome the sustained in-service applied stresses and keep the total magnitude of stress below the SCC threshold, the SCC synergy can be broken.

Quantitative residual stress measurement methods, including x-ray diffraction (XRD), can be used to characterize the stress state of components that may be susceptible to SCC either before or after they have been put into service. The effectiveness of a stress management methodology must be quantitatively verified to ensure that a compressive residual stress of sufficient magnitude has been installed, meaning that it overcomes any in-service applied stresses sothat the total residual stress level remains below the SCC threshold. In the case of the data shown in Figure 2, residual stress measurements via XRD were used to compare the effects of grinding and shot peening on the surface and subsurface residual stress state of a component prior to being placed into service. From this figure, it is clear that the residual stress of the component became more compressive after being shot peened. Once the synergy of the SCC triangle has been broken, the susceptibility of the component to SCC in service can be significantly diminished or eliminated altogether, thus improving its in-service life and reliability.

FatigueWhen turbomachinery components undergo cyclic loading, they can be susceptible to high-cycle fatigue (HCF) or low-cycle fatigue (LCF). In cases of LCF failures, the in-service stress exceeds the cyclic elastic limit of the material. LCF is characterized by cumulative fatigue damage associated with failure occurring in the range of 104 to 105 cyclesand multiple cracks in highly stressed areas. In LCF, residual stresses can evolve with cumulative fatigue damage and can be monitored periodically at predefined inspection intervals to assist in assessing component condition. It has been demonstrated that LCF life is sensitive to changes in residual stress. A 5 to 10% difference in stress can result in a 50% difference in life; thus, errors in the representation of total stress have a profound effect on life if residual stress is not in the equation.

At longer fatigue lives, as in the case of HCF, failures generally initiate at precise stress-concentration sites, with cracks propagating from a single initiation. In HCF, residual stresses remain constant until very close to the end of a component’s life; thus, an understanding of the residual stress state at the start of life is critical.

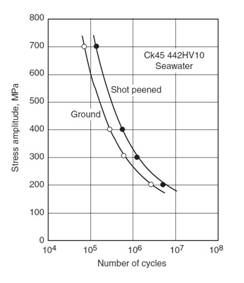

Figure 3: Bending fatigue S-N curves for Ck45 steel tested in sea water[/caption]

The impact that surface and near-surface residual stresses have on fatigue life underscores the importance of studying the effect of surface treatments and manufacturing processes. If reliable fatigue-life estimates are to be made (for example, via fracture-mechanics predictions), it is necessary to accurately characterize the residual stress fields.It is well known that fatigue life can be extended and failures mitigated by the introduction of engineered residual stresses via a wide variety of processes, including Cx, LSP, shot peening, cavitation peening, burnishing, UIT, and others. Figure 3 illustrates the positive effect of shot peening on fatigue life.To maximize their effectiveness, such treatments should be optimized for the specific application. By obtaining accurate information about the in-service loading spectra, material properties, component geometry, and residual stress fields, more reliable life-assessment and fracture-mechanics predictions can be made.

ErosionThe interaction of liquids or particles in the gas path of turbomachinery can result in the erosion of certain components. The loss of material due to erosive impacts can compound into a loss of cross section, the formation of pits, and eventually the formation of micro-cracks at the surface. In combination with cyclic loading, the stress concentrations at a crack tip may provide sufficient energy for fatigue cracks to initiate and propagate. Steam turbine blades that operate at relatively high temperatures can be especially susceptible to erosion resulting from the exfoliation of tubing scales in the system or from liquid droplet erosion. Understanding and managing the residual stresses at susceptible locations, such as the leading edge of a blade, can assist in delaying or mitigating the initiation of fatigue cracks where erosion damage is present and presumably unavoidable. By increasing the effective depth of compressive residual stresses at these critical locations, the tolerance to damage can be improved. In such cases, deeper-reaching engineered residual stress may be required as the allowable material loss increases; however, conventional shot peening alone may be insufficient, and deeper compressive layers may need to be introduced via LSP or UIT.

CreepCreep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses; moreover, this process can be accelerated with increasing temperature. With time, creep may result in a fracture via creep rupture. High engineered compressive residual stresses ahead of crack tips delay creep crack initiation and increase creep initiation life. Conversely, high tensile residual stresses due to unmanaged fabrication processes can promote creep crack initiation and decrease the time to crack initiation.It is important to note that residual stresses have little or no effect on creep crack growth rates; therefore, the surface and near-surface residual stresses are the most critical when engineered residual stresses are introduced to prevent or delay their initiation. Since deeper-reaching compressive stress processes such as LSP or UIT do not impart the highest compressive residual stress at the surface, a double-peening process may be desiredfor two reasons: first, to provide the maximum compressive stresses at and near the surface andsecond, to provide deeper-reaching compression below. Such double-peening treatments can be optimized and their effects maximized by measuring residual stress post process.

Figure 4: Measuring residual stress on a turbine blade via the x-ray diffraction technique[/caption]

Quality assurance and inspectionOnce the optimal engineered residual stress fields have been established and formally defined for components of interest, they can be monitored and audited over time to confirm that components have been correctly processed by a given supplier. It should be stressed that the selected methodology of measurement must be accurate, quantitative, and suitable for the measurement of surface, near-surface, and subsurface residual stresses so as to account for both crack initiation and propagation considerations in life modeling and analysis. An example of XRD being applied to the measurement of engineered residual stress in a turbine blade can be seen in Figure 4.

(The author is lab manager at PROTO Mfg, which supplies instrumentation for the characterization of materials such as x-ray diffraction (XRD) instruments: residual stress and retained austenite measurement systems, powder diffractometers, Laue single-crystal orientation systems, and high-resolution diffractometers.)