MAN Diesel & Turbo bags 100th order for integrally geared centrifugal compressor

MAN Diesel & Turbo has broken the century mark with its latest order for integrally geared centrifugal compressor, for air separation. It is a key component in air separation trains and the company’s AIRTRAIN and AIRMAX trains cover a broad spectrum.

With oxygen production volumes of 500 to over 7000 tpd (tons per day), they are particularly in demand for the production of liquid hydrocarbons (XtL = X-to-Liquid). With the latest order for three AIRMAX machine trains, exactly 102 integrally geared centrifugal compressors for air separation trains have been ordered since 2001.

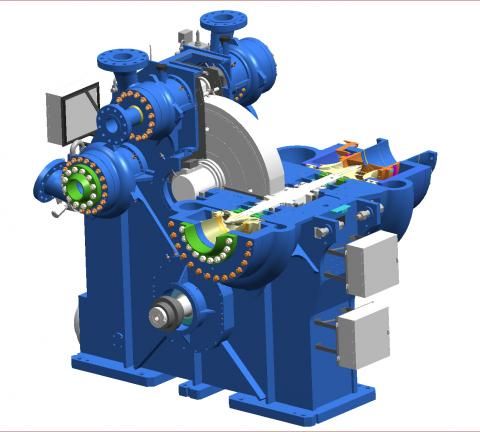

Each train consists of three MAN turbomachinery units – a main air compressor, a centrally located steam turbine drive unit and a downstream air compressor. An integrally geared centrifugal compressor (RG) serves as the downstream air compressor. It increases the pressure of the pre-pressurized air with the help of up to six compressor stages that are arranged around a single casing with integral gear unit.

Rectification process

The benefit is that a single drive is sufficient to operate all stages. The compressed air is then fed to the rectification process. Rectification is a thermal separation process that separates the air into its main components (oxygen, nitrogen and various noble gases).

Tamer Bayri, Vice President Sales & Contracts at MAN Diesel & Turbo in Berlin said, "China is a booming market for air separation plants. They are installed there to produce large volumes of oxygen and are required primarily for the processes of coal liquefaction and gasification." These industrially produced liquid hydrocarbons from coal (known as CtL - Coal-to-Liquid) are helping the country to become more independent. They can be used to manufacture commodity chemicals and fuels, thus reducing reliance on expensive oil imports.

"The industrial plants for this process are getting bigger and bigger," said Bayri. "This means that the size of our machinery is growing. Secondly, more trains are needed." As a result, the MAN Diesel & Turbo Berlin works, which manufactures integrally geared centrifugal compressors, has not only had to build ever bigger casings over the past years, but also had to manufacture an increasing number of machines per order. This has posed new challenges both for the design and production departments.

Dr. Harald Stricker, Vice President Engineering in Berlin, explains: "We designed the first integrally geared centrifugal compressors for air separation trains 13 years ago, for a power output of 10 to 15 MW. Today, this has risen to 30 MW."

Its consequences, according to Stricker are that you can't just upscale an existing RG. “We have had to constantly adapt and develop each component for each individual order." This is the case for all components of an RG – compressor stages, inlet guide vanes and integral gear units.