Manufacturers losing one trillion a year to machine failure

A study of major industrial firms by Senseye finds that large facilities lose 27 hours a month to machine failures on average at the cost of $532,000 for each hour of unplanned downtime.

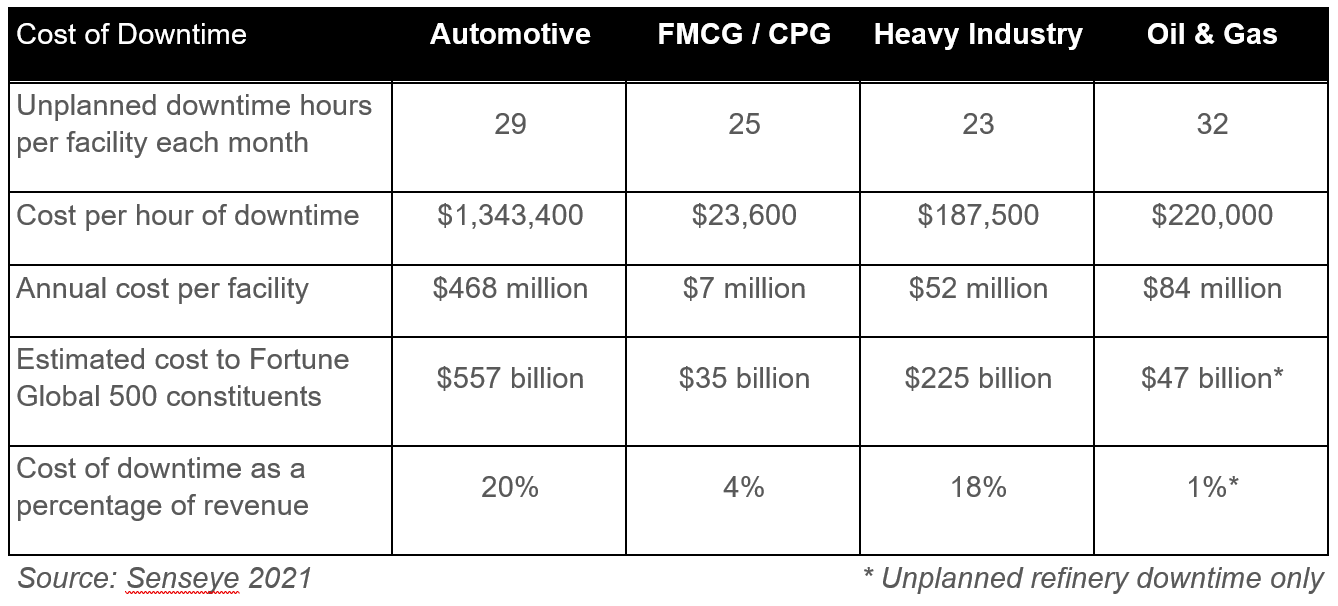

A study of major industrial firms by Senseye finds that large facilities lose 27 hours a month to machine failures on average at the cost of $532,000 for each hour of unplanned downtime. These losses are estimated to total 3.3 million production hours, worth $864 billion per year across Fortune Global 500 industrial companies.

The True Cost Of Downtime report shares findings from a study of 72 multinational industrial and manufacturing companies. It reveals that, on average, large plants lose 323 production hours a year. The average cost of lost revenue, financial penalties, idle staff time and restarting lines is $532,000 per hour, amounting to $172 million per plant annually.

“Unplanned downtime is the curse of the industrial sector,” said Alexander Hill, Chief Global Strategist at Senseye. “When expensive production lines and machinery fall silent, organizations stop earning, and those investments start costing rather than making money.”

Unplanned downtime levels were highest in the automotive sector, where plants lost 29 production hours a month, on average, at the cost of $1.3 million per hour. As a result, automotive vehicle and parts manufacturers are estimated to lose $557 billion and 414,800 hours a year. 67% of automotive companies said predictive maintenance was now a strategic objective.

Fast moving consumer goods (FMCG) & consumer packaged goods (CPG) manufacturers lose 25 hours a month to unplanned downtime at the cost of $23,600 per hour. This amounts to 1.5 million hours and losses of $35 billion a year. 72% of FMCG companies reported that predictive maintenance had become a strategic initiative.

Mining, metals and other heavy-industrial companies lose 23 hours per month of production time to machine failures at the cost of $187,500 per hour. This equates to 1.2 million unplanned downtime hours a year, costing $225 billion cumulatively. 60% of heavy industrial companies have made predictive maintenance a strategic priority.

Oil and gas producers suffer 32 hours of unplanned downtime each month, on average, at the cost of $220,000 per hour - amounting to $84 million per facility. In refineries alone, losses to are estimated to total $47 billion from 213,000 downtime hours. 82% of oil and gas respondents said predictive maintenance was a strategic objective, the most of any sector surveyed.

Senseye’s study also showed that more than two-thirds of large industrial organizations have made predictive maintenance a strategic objective and that one-in-five have established in-house predictive maintenance teams to lead these initiatives. 51 percent of organizations said they already performed some condition monitoring and 87% that they collected at least some of the data that can be used to support predictive maintenance.