Types of centrifugal compressor configurations

Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. The most fundamental configuration of a centrifugal compressor is the straight-through design. This layout is composed of one or more impellers, aligned in the same direction, contained within a single casing fitted with a single inlet nozzle and a single discharge nozzle to accommodate the gas flow.

The article contains excerpts from the paper, “Centrifugal Compressor Configuration, Selection and Arrangement: A User’s Perspective” by Mark R. Sandberg of Sandberg Turbomachinery Consulting at the 2016 Turbomachinery Symposium.

While the number of stages contained within the section is a function of the produced head requirements, there are practical limitations to the number of stages that can be included. One of these limitations is connected with the resulting discharge temperature that is a function of the overall pressure ratio, compression efficiency, and gas thermophysical properties. This temperature limitation may be due to material temperature limits of components within the compressor or gas temperature limits imposed by other equipment or the process in which the compressor is operating. An important limitation in the number of stages allowed in a single, straight-through configuration is associated with lateral rotordynamic considerations. Current beam-style designs limit the number of stages in a single casing to 10 or less, however, this may be subject to the magnitude of the flow coefficients of the stages.

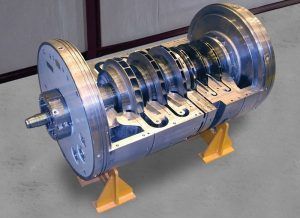

Dresser-Rand Datum compressor[/caption]

Beam-style compressors are configured with all of the impellers and a balance piston, if applicable, on the rotor located between two radial bearings. Lateral rotordynamic stability is one of the primary considerations in limiting the number of stages to 10 or less. Regardless of the number of stages provided in a design, it is good practice to provide a preliminary stability screening utilizing the evaluation method of the critical speed ratio (CSR) plot provided in API 684, “API Standard Paragraphs Rotordynamic Tutorial: Lateral Critical Speeds, Unbalance Response, Stability, Train Torsionals, and Rotor Balancing.”

This analysis examines both the rotor flexibility (in terms of the rotor operating speed to first rigid critical speed ratio) and the average density of the gas which impacts the magnitude of the aerodynamic excitation forces generated. Other similar figures that have been generated through the years have replaced average gas density with the product of discharge pressure and pressure differential across the compressor. The information required to evaluate rotordynamic stability using this plot is normally available on API 617, “Axial and Centrifugal Compressors and Expander Compressors for Petroleum, Chemical and Gas Industry Services,” data sheets.

Another useful parameter that can be calculated using data sheet information is the bearing span-to-impeller bore diameter ratio of the rotor. It is more likely that lateral stability is provided if this ratio is 10 or less. Values above 10 should be evaluated in more detail, and any value above 12 should be considered for an API 684 Level II stability analysis. The pressure profile that is present around each impeller results in an unbalanced axial thrust force in the direction from the back disk towards the eye of the impeller. A summation of these unbalanced forces represented by each impeller is balanced by the combination of a balance piston at one end of the rotor and a thrust bearing. The balance piston is provided with a cross-sectional area where discharge pressure is imposed on one end of the piston and suction pressure on the other, partially negating the unbalanced axial force due to the impellers.

Variants of the beam-style, single section, straight-through design exist that deserve identification. One of these is the overhung, single stage design that is commonly utilized in pipeline applications where a relatively low pressure ratio is required. The layout of this design includes a single impeller placed outside of the bearing span. The number of impellers included in this design is normally limited to a single impeller due to overhung moment influences on lateral rotordynamic behavior.

Another variant of the single section, straight-through configuration is the integrally geared compressor. In the simplest form of this design, a single impeller is directly connected to the end of a pinion which is driven by a bull gear to a specified speed. These impellers are often of an open design, which means that the vanes are connected to the back disk but there is no cover provided that encloses the flow path on top of the vanes. Although the lack of an impeller cover increases leakage, this is offset by the increased head generating capability due to higher allowable tip speeds when compared to a shrouded impeller. More complex versions of the integrally geared compressor exist where impellers are attached to both ends of the pinion and multiple pinions are associated with a single bull gear. The rotational speed of each of the pinions can be optimized to enhance the overall efficiency of the compressor.

Compound Configuration

There are a substantial number of applications where inter cooling of the gas is required to maintain temperatures at acceptable levels. One solution is to provide multiple, single section casings with inter cooling provided between the casings. An alternative is to provide multiple sections within a single physical casing. This is known as a compound section configuration. A benefit of the compound configuration is reduced footprint, since a single casing requires less space than two casings with double the amount of radial bearings and the space required by a coupling between two separate casings. Additionally, sometimes process requirements dictate the need for a side stream addition or extraction to be available at some intermediate pressure of the overall compression application. This is another important benefit of the compound compressor configuration.

While there is significant advantage in applying the compound configuration when appropriate, there are some drawbacks to this design. One of these is the fact that inlet and discharge nozzles for each section are required to be supplied on the casing. Adequate spacing to accommodate these nozzles on the casing has to be considered when the equipment supplier lays out the casing internal and external design. Although there are no theoretical limitations on the number of sections contained within a single casing, limits do exist on the space available in a given casing to accommodate a large number of sections.

A pressure differential also exists between the discharge of a given section and the suction of the following section due to pressure losses that must exist in the piping and equipment between the two sections of compression. The differential pressure that exists within the compressor casing results in the potential for leakage from the lower pressure section discharge into the higher pressure section suction. This results in an overall loss of efficiency of the compressor. Some type of a controlled leakage internal seal must be provided to limit the amount of leakage and increase the compression efficiency. The addition of the seal requires some amount of space and a reasonable rule of thumb is that each seal displaces a potential stage of compression. Accordingly, a reasonable estimate of the maximum number of stages available in a two section compressor is nine. This reduces to a maximum number of eight for a three section machine. Notwithstanding the issue with space available for nozzles on the casing, it is fairly obvious that a compound compressor with more than three sections is only feasible for relatively low compression ratios per section.

One final characteristic of the compound design that should be identified is concerned with the transient operation of the machine. Upon shutdown, a compressor will settle-out to an equilibrium pressure somewhere between the suction and discharge pressures that is dependent upon a number of factors, primarily relative suction and discharge volumes associated with the compressor and its connected systems. This settle-out pressure calculation is straightforward for a single section casing. In the case of a casing with multiple sections, however, each section will settle-out to a different pressure level and then all sections will settle out to a common settle-out pressure due to leakage through the controlled leakage seals between each section. Associated piping, vessels, and other process equipment must be designed to accommodate this combined settle-out pressure.

Back-to-Back Design Configuration

A unique version of the compound design is the back-to-back configuration, where the stages of the first section are oriented within the casing opposite to the second section. Generally the eyes of the impellers of each section are oriented towards the shaft ends of the casings. The back-to-back configuration is similar to the compound design with the ability to provide inter cooling and mass flow addition or extraction between the sections, although this is an option. A significant advantage of the back-to-back design is its inherent characteristic to reduce, and roughly balance the axial thrust force generated in the stages of each section. Since the two sections are oriented in an opposite direction, the unbalanced axial thrust forces of each section are acting in opposite directions. This is a very distinct benefit in high pressure, high density compression applications such as gas injection services where unbalanced thrust forces can be substantial.

In such an application the duty and size of the thrust bearing could be prohibitive without the balancing feature. A close clearance, controlled leakage seal must be provided between the two sections in a similar fashion to the compound machine design. Unlike the balance piston required in the other designs, this internal, controlled leakage seal (commonly known as the division wall seal) is only subject to approximately half of the overall differential pressure of the two section casing. While this reduced pressure difference has the potential to reduce internal leakage, this can be offset by a possible need for increased clearance due to the location of the seal near the center of the bearing span with the accompanying increased deflection of the shaft in this location.

Additionally, the location of the division wall seal near the center of the rotor has previously been a challenge with the potential for aerodynamic excitation. Technology and design developments over the past several years have reduced this issue with the introduction of hole pattern seal designs and swirl brakes. Final settle-out conditions of the back-to-back design are similar to the compound configuration, where each section settles out to a different pressure level followed by an equalization of pressure between the two sections to a common settle-out pressure. It is critical to design associated piping and equipment to this common settle-out pressure to prevent overpressure of equipment, particularly on the suction side of the lowest pressure section. An additional phenomenon that is observed with the back-to-back design concerns the leakage across the division wall seal and its impact on the flow leaving the first section and entering the second section. This flow will actually be the sum of the first section flow rate, any side stream flow, and the division wall leakage which may impact inter-stage process piping, process equipment and inter cooler duty and design.

Double Suction Configuration

Significant inlet volumetric flow rates can result in excessive magnitudes of impeller flow coefficients. Additional detail on the impacts of high flow coefficients will be explained in more detail, however, beyond a certain point it is beneficial to reduce the flow into an individual section. One way to accomplish this is to provide parallel sections in separate casings. An alternative is to select a compressor of the double suction design configuration. This design is geometrically similar to the back-to-back configuration, but both sections are of equal design. The inlet flow rate is split in half externally and introduced into the casing through two suction nozzles at each end of the casing. Upon passing through the two equal sections, the flow is combined into a single discharge nozzle.

Double Suction Design Configuration

Given that the two sections of the compressor are oriented in separate directions and are aerodynamically similar, there is theoretically no net axial thrust produced. Since there can be differences in both internal and external suction losses and manufacturing tolerances between the two opposed sections, some small amount of axial thrust is anticipated and a thrust bearing is included, albeit limited in capacity. The double suction configuration is very useful for large volumetric flow rates that are often associated with low inlet pressures as stated previously. It should be assumed that the maximum number of stages per section is limited to no more than four due to considerations of the dual suction inlets and single, combined discharge. Although possible, this machine design is probably limited to a single section of compression with no more than two suction nozzles and a single discharge nozzle.

Sideload Design Configuration

A final centrifugal compressor configuration that warrants further explanation is the sideload design. This configuration is similar to the compound design in that multiple sections oriented in the same direction are contained in a single casing. The sideload design is substantially different because there are no intermediate intercooled flows that leave and re-enter the casing. One or more sidestream flows may be introduced or extracted from the casing, however, all or most of the flow from the preceding section does not leave the casing. Sidestream flows that are introduced into the casing mix with the discharge of the preceding section, and any cooling occurs through the mixing of the predominately lower temperature sidestream.

Sideload Design Configuration

The sideload compressor design is well-suited for refrigeration applications where the refrigerant is introduced at progressively lower temperatures to the lower pressure sections. These sidestreams originate from economizers that operate at intermediate pressure levels in order to increase the overall efficiency of the refrigeration process. Temperature increases of the gas in a given section are reduced by the mixing of the sidestream flow into the suction of the following section of the compressor, effectively maintaining the gas temperature through the machine at reasonable levels. It is possible to extract flow from one of these sidestreams, but this tends to be an exception. Limitations on the potential number of sections and stages per section do exist for the sideload design. Assuming the rule of thumb that a limit of ten stages are allowed in a single casing and that any sidestream nozzles are roughly equivalent to a stage, it is evident that there are limitations to the number of sections that can be contained in such a design.

Recent trends in some applications, particularly liquefied natural gas (LNG) processing, are pushing volumetric flows to ever-increasing levels. This results in increasing flow coefficients of individual stages with increasing axial lengths required for each stage of compression. Accordingly, this reduces the number of stages further. This will be discussed in more detail in the next section.

There are additional complications associated with the sideload compressor configuration. One of these is involved with the process control of the machines themselves. Generally each section of compression is protected from the potential to surge through a recycle line dedicated to that section which prevents the volumetric flow rate from falling below a prescribed level. This is complicated in the sideload configuration because recycle flow can only be obtained from the final discharge. Relative effects of flow capacities of each section and the preceding sections influence the selection of these minimum volumetric flows. It is also more difficult to monitor the a aero-thermodynamic performance of these machines since mixture temperatures of the internal gas flows are not measured, thereby making individual section performance only able to be estimated based upon predicted section efficiency.

While it is acknowledged that additional centrifugal compressor design configurations exist (e.g. isothermal designs), they tend to be very unique and limited in application. As noted previously, the configurations that have been described are those that are most commonly observed in industry and warrant the descriptions provided. It should also be noted that multiple configurations or combinations of configurations may be applied to any potential application. This flexibility provides the user and purchaser both opportunities and challenges to select the most optimum combination in many cases.