Varnish is Preventable

A proper turbine-oil lifecycle management strategy ensures a varnish-free lubricating system.

Gas turbine lubrication systems are commonly plagued by varnish formation. Although top-treat solvency enhancers, varnish filtration technology, system cleaners, and flushing are solutions to varnish in a turbine lubricating system, the best and most effective approach is not letting it form in the first place.

Varnish results from oil degradation accumulating beyond the oil’s capacity to keep it solubilized. High temperatures, cavitation, electrostatic discharge, and the presence of catalytic contaminants are all potential contributors to the degradation of lubricant molecules. Regardless of the source, once the oil has become saturated with oxidation and thermal degradation byproducts, it will deposit these components as varnish throughout the system. While steps can be taken to delay degradation through additives and operating conditions, oxidation is not preventable; it is inevitable, as defined by the laws of thermodynamics. However, it is highly predictable and can be managed so that the negative consequences of excessive degradation, i.e., varnish, are preventable.

Creating, utilizing, and executing a proper turbine-oil lifecycle management strategy ensures a varnish-free lubricating system for the entire fluid-drain interval.

The key components are:

- Start with a clean system.

- Select a lubricant that provides excellent resistance to varnish formation.

- Perform the correct oil analysis tests at the right sample intervals.

- Proactively manage the varnish tendency of the fluid as it ages.

- Schedule an oil change once the data indicates the fluid is nearing the end of its useful life.

START WITH A CLEAN SYSTEM

The key to maximizing the life and performance of your turbine oil is to give it a clean, contamination-free environment from the start. For new units, that means flushing the system with a sacrificial change of oil before the initial fill. For a system undergoing a service-interval change, that means ensuring there is no residual varnish or degraded oil from the previous fluid that could contaminate the new oil. For systems known to have varnish or suspected varnish, use one or more mitigation technology, such as varnish filtration, varnish solvency enhancers, and/or oil system flushing.

SELECT A LUBRICANT

While many commercial lubricant technologies advertise properties that meet the basic fluid requirements for turbine manufacturers, not all these fluids will provide equal, long-term performance in application. Additionally, there are multiple technology approaches to fluid formulation for varnish resistance. Using a technology with robust, inherent varnish resistance and solubility provides an advantage in managing the fluid lifecycle and achieving a long useful oil life.

PROPER OIL ANALYSIS TESTS

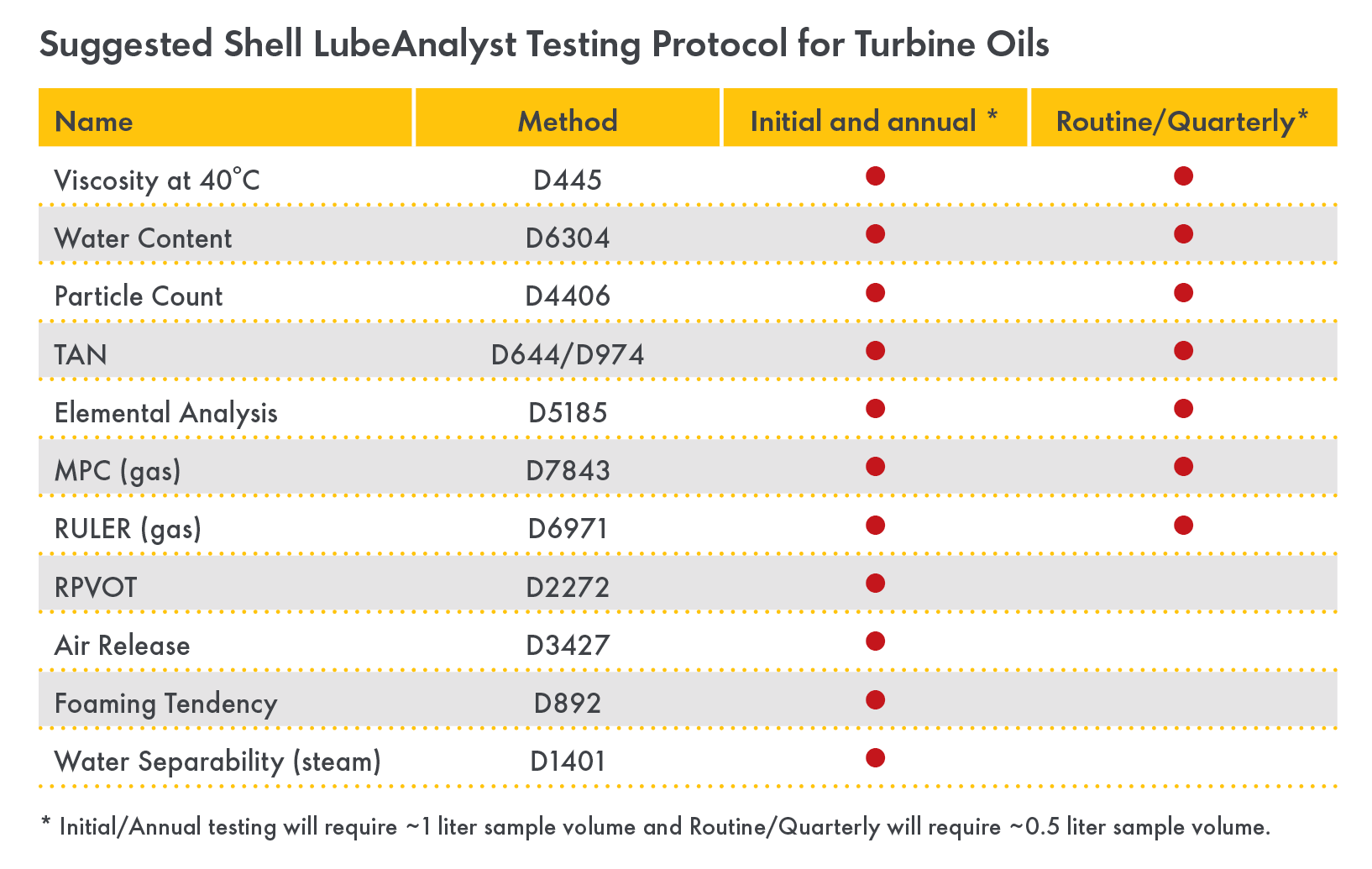

A critical component of managing the oil’s lifecycle to prevent varnish formation is performing the proper oil analysis tests at the correct intervals. The table below details the tests and intervals that should be utilized for varnish formation prevention. The most important sample in the turbine oil process is the first sample taken in the fluid’s life: It should be pulled in the first 8 to 24 hours. This sample will serve as the baseline for all future sample comparisons. A fresh, uncirculated sample as the baseline is not recommended.

BE PROACTIVE

All oil degrades with time and use, and thus it will eventually reach the end of its useful life regardless of prevention and intervention. However, measures can be taken to maximize the oil’s useful life, especially concerning varnish potential. Varnish formation is preventable by ensuring the oil does not exceed its solubility for varnish precursors and degradation byproducts. Using the prescribed analysis protocol provides the necessary information to keep ahead of this occurrence. As data predicts cautionary levels of degradation components in the oil, mitigation technologies, such as varnish filtration units and a varnish solvency enhancer, can control the accumulating degradation components.

SCHEDULE AN OIL CHANGE

Once the oil-testing data indicates the oil is nearing the end of its useful life (6 to 18 months), begin making plans to replace the current fluid. A varnish solvency enhancer and an intermediate flush ensure the system is clean for the new fluid and help maximize its potential.

Varnish can be prevented. Following the prescribed key components to fluid lifecycle management provides the best approach to maximize the life of your lubricant and remain varnish-free.

Christopher Knapp is a Product Application Specialist at Shell Lubricant Solutions.