Automating Power: Rolls-Royce’s Software Offers Full Control

The mtu NautIQ and mtu EnergetIQ automation systems allow marine vessel and power-plant operators to fully control and monitor system data, assets, and user management from a single screen.

Rolls-Royce Power Systems provides mtu-brand high-speed engines and propulsion systems for ships, heavy land, rail, defense vehicles, and the oil and gas industry. The portfolio also includes diesel and gas systems and battery containers for mission-critical, standby and continuous power, combined heat and power generation, and microgrids. In addition to reciprocating engines and electrical hybrid systems, Rolls-Royce supplies ship and power-plant automation software that allows complete control over complex infrastructures.

mtu EnergetIQ Manager for energy applications and mtu NautIQ Master for ship applications are specifically tailored for their industries, but each serves the same purpose: allowing operators to oversee and control the entire ship or plant.

MTU ENERGETIQ

The mtu EnergetIQ Manager platform is a comprehensive solution for power plant controls that can be individually customized to customer requirements. Its most recent update reinforces security, scalability, and intuitive use, allowing operators to manage data, assets, and loads with full control and monitoring from one screen.

“[Its] job is to work out the ideal mix in terms of power generation, power storage, and the power demand—both currently and for the future,” said Jan Henker, Senior Expert of Automation and Controls, Rolls-Royce Power Systems. “In the specific case of a microgrid, mtu EnergetIQ Manager, keeping in line with the customer’s wishes, would determine the current energy mix based on contemporary and future weather data, the prices on the electricity exchange, and the customer’s energy demand using AI (neuronal networks) for predictions and sophisticated problem-solver algorithms for optimization.”

It offers three key advantages:

- Scalability: The system can be scaled on demand, separating control units for real-time control, monitoring, and protection from high-performance PCs for data management, visualization, and reporting. Operator stations can be added throughout the facility, across workshops and offices, and mtu and third-party components can be integrated on different levels.

- Redundancy: 24/7 data synchronization between master and backup controllers provides a range of redundancy options, with additional offerings for redundant control networks and related assets.

- Future-Proof: In addition to information and control availability from various operating stations, new assets can be integrated with minimal software parameter changes to future-proof the system.

Zooming out, the solution’s full functional scope includes energy and power management, switchgear controls, and data and alarm management, covering all control and data acquisition tasks—from sensor to cloud. mtu EnergetIQ Manager automates generation, storage, and demand.

“In pure generation plants without storage, the mtu EnergetIQ Manager maximizes the efficiency of the generator sets (depending on load factor) by calculating the number of generator sets required to meet power demand and capacity reserve and by performing load-sharing between running generator sets,” Henker said.

The system also has differing functionalities across on- and off-grid applications: On-grid operation is used for power trading, grid services, and peak-load shaving. Off-grid applications include stabilizing the power supply and lowering costs and emissions.

Rolls-Royce Power Systems plans to update mtu EnergetIQ Manager for new applications, including equipment health management, analytics for battery systems, and predictive maintenance. New genset controllers are also coming soon.

MTU NAUTIQ

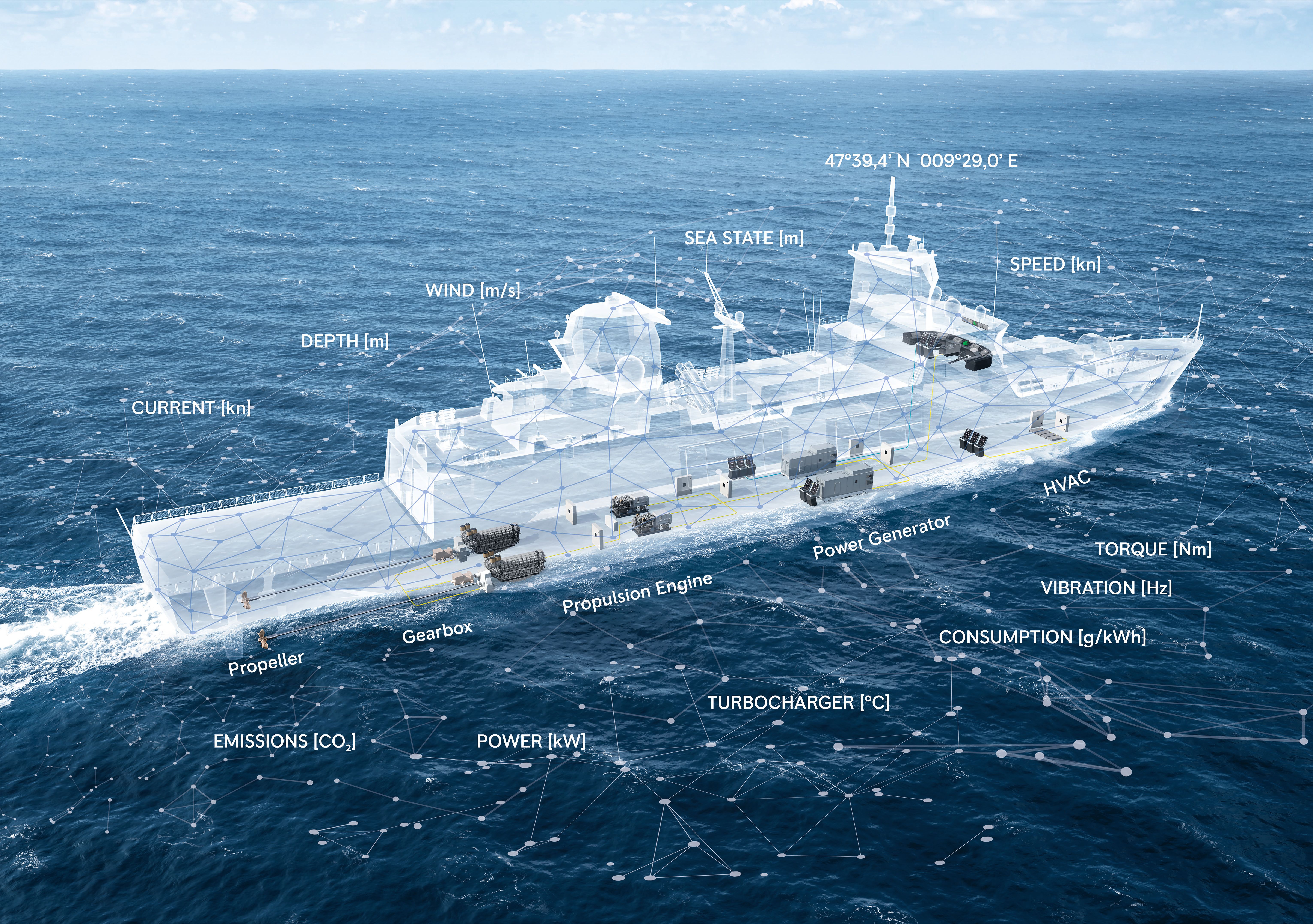

The mtu NautIQ automation portfolio, applicable to new-builds and retrofittable to older vessels, allows monitoring and control from “bridge to propeller.” The “Master” iteration is Rolls-Royce’s most recent Integrated Platform Management System (IPMS), which enables the integration or future-proof upgrade of additional hardware, software, and auxiliaries throughout a vessel’s lifecycle, offering customers long-term planning and reliability.

“There are several advantages to our automation systems: The crew can focus on its main tasks and competencies—for small crews, this is a big advantage,” said Simon Gallagher, Director of mtu NautIQ Solutions, Rolls-Royce Power Systems. “The technical complexity and maintenance tasks can be managed by the fleet-management team on land. Decisions are made based on live data, not on historical data. Cloud analytics and AI technologies can be made available for operators.”

Rolls-Royce's solution for navies and commercial ships is the automation system mtu NautIQ Foresight.

Future-proofing is its primary feature:

- System parts are selected from suppliers capable of delivering components well into the future, and Rolls-Royce can manage obsolescence with partners to support customers.

- It can be installed on vessels with high-sensor/ actuator counts and complex automation requirements, accommodating large data-set interfaces emerging with the “big data” trend.

- Similar to mtu EnergetIQ, the system allows a high degree of integration with third-party systems, with all system elements fully traceable through detailed system configuration.

There are plenty of upcoming developments for mtu NautIQ: “A new version of the platform software, Winmon, is being upgraded to Winmon9_1,” Gallagher said. “This is significantly faster than the previous version and runs on lower-power hardware. It will also include some enhancements: an OPC-UA interface for third-party system integration; a feature-rich damage control system with dynamic kill cards; vector graphics for improved HMI performance; and multi-language capabilities. Another area of improvement is cybersecurity: The system is being developed in alignment with IEC62443 and has significant cyber features. Another system using Winmon9_1 is the new BVNG Premium system.”

FUTURE TRENDS

“Rolls-Royce Power Systems recognizes the importance of combating cybersecurity as a critical trend in power-plant automation, and we take it seriously by meeting critical industry standards,” said Kevin Daffey, Senior Vice President of Mobile Automation.

According to Henker, on-premise data management and analytics solutions, particularly for critical infrastructure, are also upcoming trends. The creation of insights from the plant data can optimize processes, save emissions, and prevent downtime.

A couple of trends are on the horizon in the ship automation software industry. Gallagher said that the accumulation of big data from various platforms requires IPMS to interface, gather, and make this data accessible onboard marine vessels, onshore, and in the cloud. Additionally, platform issues must be identified early so dynamic analysis and fault prediction using digital-twin comparisons can be integrated into ship automation software.

As highly experienced engineers at sea become rarer, there is a growing need for tools such as machinery data insights, onboard training, and equipment documentation, which are all integrated into ship automation to enable shipboard engineers to pre-empt and prevent machinery breakdowns, apply intelligence to maintenance, and make repairs easier.