Vendor spotlight: Elliott Group

Elliott Group manufactures centrifugal and axial compressors, steam turbines, power recovery expanders, cryogenic pumps, and cryogenic expanders.

Elliott Group headquarters in Jeanette, PA

Elliott Group has a century-long legacy of manufacturing rotating equipment. Headquartered in Jeannette, Pennsylvania, Elliott employs more than 1,600 employees at 32 locations worldwide, with approximately 900 in Jeannette. Since 2000, Elliott Group has been responsible for the global turbomachinery operations of its corporate parent, Ebara Corporation, based in Tokyo, Japan.

Elliott’s dual engineering and manufacturing centers in Jeannette, Pennsylvania (USA) and in Sodegaura, Chiba (Japan) produce rotating equipment including centrifugal and axial compressors, steam turbines, power recovery expanders, cryogenic pumps, and cryogenic expanders. These range from machines of several hundred horsepower (hp) to over 120,000 hp. A network of full-service repair centers, field service teams, and sales and support offices extends throughout North and South America, Europe, the Middle East, and Asia.

Company products and technologies are broadly targeted toward the energy industry. Typical markets for equipment include refineries, petrochemical plants, liquefied natural gas (LNG) production and transport, and liquefied gas processing. Many of Elliott’s products are engineered and customized for specific applications to achieve optimized operating goals such as reliability, efficiency, availability and low operating cost.

“Our clients rely on us to provide products that function reliably in very challenging operating conditions and environments,” said Klaus Brun, Director of R&D, Elliott Group.

For example, Elliott manufactures some of the largest compressors in the world for ethylene plants and refineries. It also has the largest fleet of refinery hydrogen compressors in operation of any centrifugal compressor manufacturer.

Customization versus Standardization

Brun noted that all compressors must be customized for a given gas, pressure, and temperature operating range. As well as the desired operating conditions, design optimization efforts address the specific application, duty cycle, and operational environment. However, components such as bearings, seals, and instrumentation rely on standardized designs. As much as possible, Elliott utilizes these proven components to enhance product reliability, reduce operational cost, and increase spare parts accessibility. But as a typical industrial compressor has an expected operational life of more than 30 years, it is imperative to create the ideal design for the desired service.

Standardization has been the traditional driver for reduced manufacturing costs in industry. However, advanced design tools and 3-D manufacturing technology have rendered this approach overly simplistic. It often results in machines that are less than optimal for a given application.

“With the widespread adoption of advanced manufacturing technologies and modern engineering analysis tools, the future of turbomachinery design lies in customization of machinery for applications,” said Brun. “Customization of each machine for its desired operating conditions allows for a product with maximum efficiency, range, and life.”

Based on exacting process requirements and specific operating conditions, Elliott custom designs compressors, turbines, pumps, and expanders with the best efficiency and range for the application, while maintaining the robustness needed for a long lifespan. As a result, many products have been operating for more than 50 years.

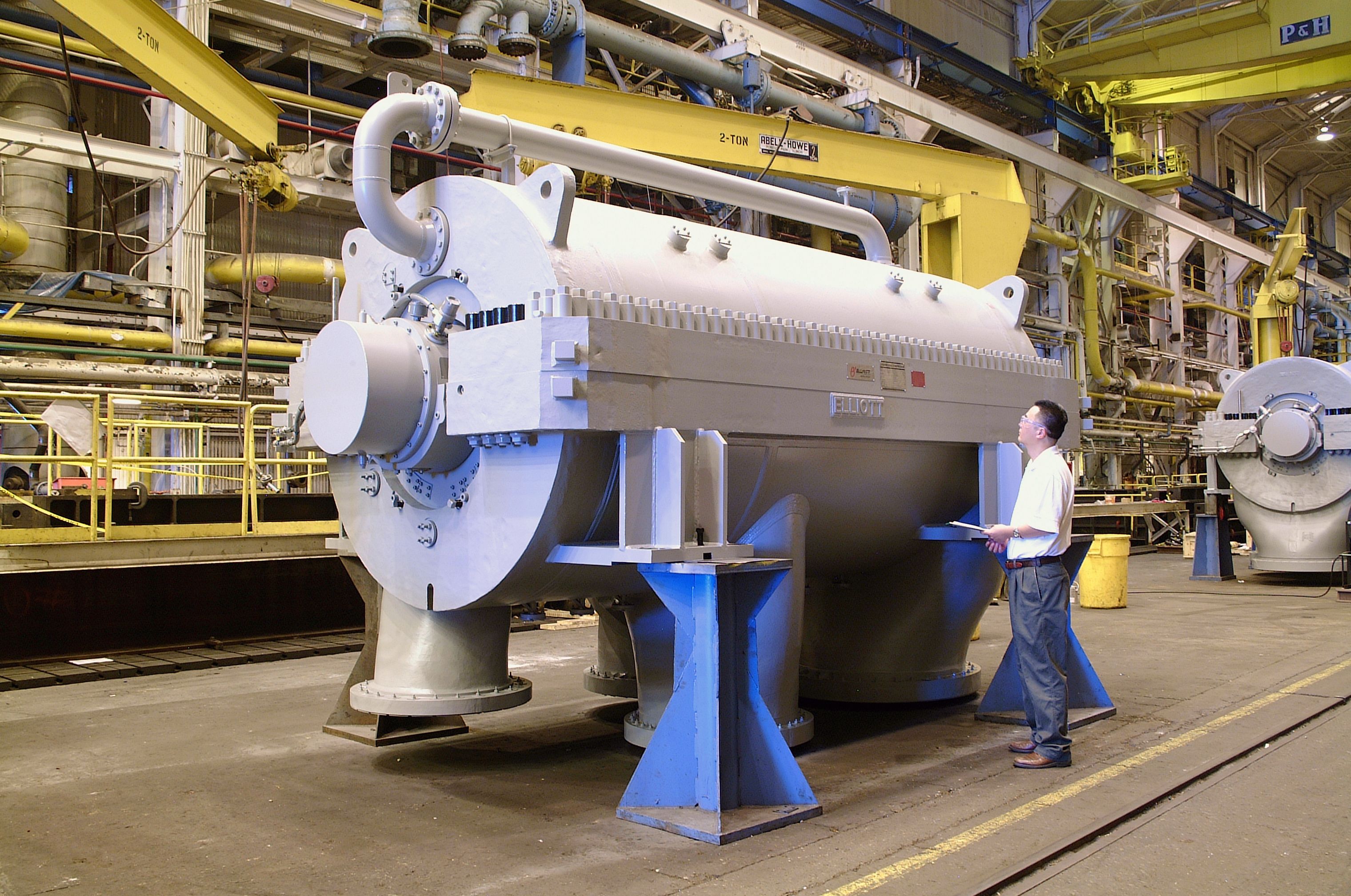

Large centrifugal compressors like this one are in service in a great many petrochemical facilities around the world.

Compressors

Thousands of Elliott compressors are in service around the world in petroleum refining, petrochemical processing, cryogenic refrigeration, LNG, oil and gas production, gas compression, and other industrial processes. The company pioneered refrigeration compression, high-pressure casing technology, the development of fabricated casings, and improved impeller welding techniques. It was also among the first to utilize magnetic bearings in critical-service centrifugal compressors.

Advances in aerodynamics, rotor dynamics, computerized equipment selection, process simulation, and metallurgy, as well as custom-engineered lubrication, seal, and piping systems have been incorporated into the latest compressor designs.

The Elliott centrifugal compressor line encompasses a wide selection of frame sizes and configurations to meet pressure, flow, and application demands. Its single-stage, overhung compressors meet API specifications and operate in continuous service in oil & gas, petrochemical, and refinery applications. Multi-stage centrifugal compressors are favored for low, medium, and high-pressure services, refrigeration applications, and low molecular weight gases.

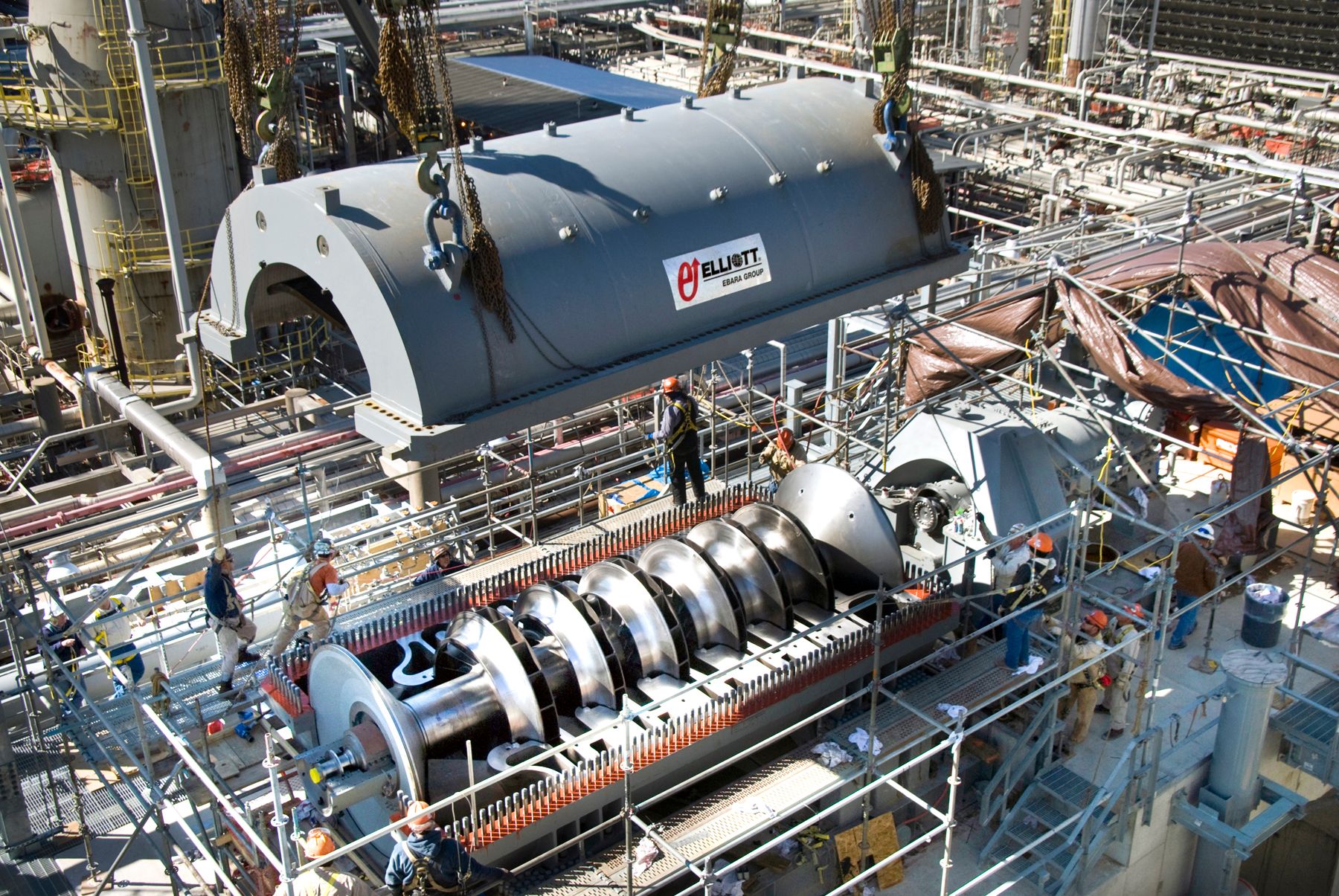

This ethylene compressor rotor is being tested at the Elliott test stand in Jeanette, PA.

Steam Turbines

With power requirements, steam conditions, and speeds constantly rising, Elliott steam turbines are rated for inlet steam conditions up to 2000 psig/1005°F and speeds up to 20,000 rpm. They range from small, 20 HP (15 kW) single-stage units, to large 175,000 HP (130,000 kW) multi-valve, multi-stage extraction condensing units. These units can be built to API standards and customized to meet exacting specifications.

Elliott YR steam turbines are found driving pumps, compressors, fans, blowers, generators, sugar mill tandems, cane shredders, paper machine lineshafts, and other applications. These are standardized models with stocked components. Single-valve, single-stage units are available in frame sizes and ratings up to 5,400 hp (4,027 kW). Multi-YR units can be deployed for improved steam consumption as they produce more power without additional steam. They can be installed in many areas where single-stage steam turbines currently operate. They are available up to 14,000 hp (10,440 kW).

There is also a high-speed, high-efficiency multi-valve steam turbine that combines the reliability of an impulse-style turbine with the efficiency of a reaction-style turbine to provide high performance in a range of refinery services. Designed to API 612 standards, the turbine has a small footprint. At typical pressure and temperature operating conditions, efficiency is greater than 80%. This 13-stage, multi-valve turbine serves as a direct drive for compressors in oil and gas-related services including hydrotreating, catalytic reforming, alkylation, refrigeration, gas boosting, and coking. Its high-speed condensing design eliminates the need for a separate gear box, reducing the amount of mineral oil, cooling water, and steam required.

In addition, Elliott steam turbine generators (STGs) support commercial energy requirements for continuous or standby power up to 50 MW, including renewable energy applications and green energy initiatives. Elliott’s steam turbine designs incorporate industry standards such as API 611 and API 612, and National Electrical Manufacturers Association (NEMA) specifications SM-23 & SM-24 when required for all new units, aftermarket conversions, and re-rates.

A technician verifies dimensional specifications on a huge Elliott compressor casing.

Pumps and Expanders

Elliott’s Cryodynamic Products business manufactures standard and custom cryogenic pumps and expanders, including submerged electric pumps and expanders in liquefied gas applications. They are used in onshore and offshore solutions for liquefaction, storage, and regasification for liquefied gas carriers, FSRU, FLNG, FSU, LNG bunkering, and LNG fueling applications. Company firsts include the first submerged cryogenic expander in 1997, the first two-phase expander in 2001, the first two-phase tandem installation in 2008, and the first floating application in 2011.

Submersible electric cryogenic pumps have a motor that is submerged in oxygen-free cryogenic liquid, removing the potential for ignition, and minimizing the number of electrical components that are installed within the hazardous area. There is no need for rotating seals, eliminating a source for leaks. This allows the design to safely accommodate caustic chemicals such as ammonia or methane. Moreover, rotating components are contained within casings that are submerged within a secondary tank or vessel, further protecting personnel from potential hazards.

Elliott provides customizes impellers of all size ranges for challenging applications.

Cryodynamics equipment is designed to operate in liquefied gases with temperatures ranging from ambient (warm) to cryogenic. The submerged motor operates in a non-conductive liquefied gas. They are available in a number of configurations for a variety of marine, land-based, floating, and small-scale applications.

Cryogenic expanders: The traditional method to let down pressure in a liquid stream used a Joule-Thomson (J-T) valve. Replacing the J-T valve with a Cryodynamics cryogenic expander improves the efficiency of the let-down process. Depending on the machine, cryogenic expanders can increase plant efficiency by 8%, reducing operating costs, and increasing LNG production.

The expander consists of an induction generator mounted on an integral shaft. The entire unit, including the turbine and generator, is submerged in the cryogenic fluid. This eliminates the need for dynamic seals, shaft couplings, generator support structure, and any concern of possible misalignment between the turbine and generator. To ensure reliability and increase mean time between overhauls, they use the same thrust equalizing mechanism used in Elliott pumps to eliminate axial thrust loads, boost bearing life, and reduce machine wear. They can be supplied with variable speed technology together with fixed inlet vane geometry to optimize expander efficiency over a range of flows and desired pressure reductions.

At the heart of the system is the variable speed, constant frequency (VSCF) controller, which can vary the speed of the generator and expander to precisely match process conditions. At the same time, power is produced at constant frequency with unity power factor. The low harmonic sinusoidal output can then be fed directly back into the plant electrical system. In processes where few operating points are expected, cryogenic expanders may be supplied without the VSCF for constant speed operation.

Each expander is fully tested at an in-house cryogenic performance test facility, simulating actual site conditions. Testing can be performed at full speed and full power with a variety of liquids such as LNG, LPG, or LN2, depending on the temperature and specific gravity of the service fluid.

The latest innovation in the company’s expander line is the upward flow, two-phase expander, which allows the expansion of liquefied gases into two-phase mixtures within its final stage. Harnessing the energy of two-phase expansion increases the expander’s generator output, reduces boil-off losses, and enhances the liquefaction process.

Elliott TH power recovery expander turbines convert high-temperature, low-pressure flue gas energy into usable power. The turbine often is used to drive compressors or generators in refinery fluid catalytic cracking (FCC) service. Recovery power for these applications can approach 50,000 hp (37,300 kW).

Elliott custom-makes compressors, expanders, and pumps for oil & gas service all over the world.

Future Developments

The company is currently developing a number of new products that aim to address several energy sector market needs ranging from alternative to conventional fossil energy. This work is being carried out in a new R&D center. The ongoing R&D program is aimed at improving existing products as well as the development of new products in the energy sector for challenging applications. Several multi-million dollar development efforts have been initiated in the areas of centrifugal compressors, steam turbines, and cryogenic pumps. ■

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)