Dry gas seal advancements address sealing pressure, temperature range, face contact, leakage and oil migration

Most compressors purchased today are delivered with dry gas seals. Overall, they have provided increased compressor reliability, improved safety and reduced process gas loss. As a result, users continue to extend the range of applications using dry gas seals.

As seal manufacturers develop their understanding of dry gas seal essentials and identify root causes for failures, design changes are delivering an improved product. This includes more elaborate seal support systems for dry gas seals.

Sealing pressure

Critical factors for achieving higher sealing pressures are seal ring material, secondary sealing elements and the secondary dynamic sealing system. Tungsten carbide and carbon graphite are often used for seal rings in many dry gas seals. However, the flatness of a carbon graphite stationary ring is difficult to maintain with larger rings at higher pressures and temperatures. Newer seal designs extend the seal’s pressure, temperature and speed range by using silicon carbide seal rings. Improved processes for manufacturing silicon carbide has extended these parameters even further.

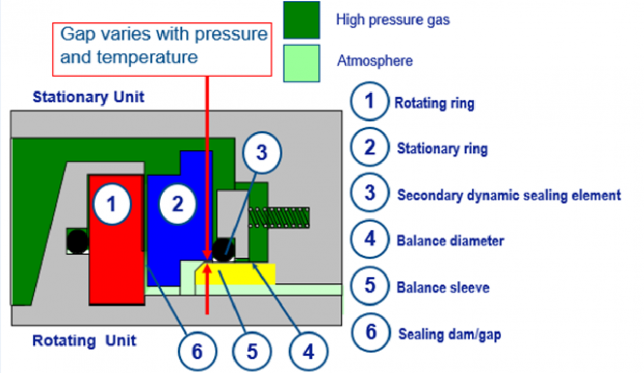

Secondary sealing elements are another important feature for accomplishing higher pressures. They seal against the compressor’s seal cavity, rotor and internal locations within the seal (Figure 1). O-rings were traditionally used for these elements, but voids in the material allow gas seepage into them. When pressures exceed approximately 800 psi, reducing pressure around the O-ring too quickly causes the trapped gas to expand before it can escape. This produces ruptures and blistering on the O-ring, preventing it from sealing again. This is referred to as explosive decompression. With 90 durometer (a standard for hardness measurement) Viton (a synthetic rubber and fluoropolymer elastomer), it typically occurs at decompression rates greater than 300 psi/minute. To overcome this challenge, polytetrafluoroethylene (PTFE) secondary sealing elements are used. PTFE is impregnated with other materials, adding additional features to produce the right seal material for high-pressure dry gas seal applications.

With secondary sealing elements managed, another concern is the dynamic secondary sealing system (Figure 2). This system allows the non-rotating seal ring to move axially and maintain an effective gap between the seal ring faces. The major components in the dynamic secondary sealing system are the dynamic sealing element and the balance sleeve.

When pressure is applied to the balance sleeve, the sleeve diameter shrinks. This increases the clearance between the seal ring inner diameter and sleeve. A balance sleeve that changes minimally as extreme forces are applied prevents extrusion from occurring. Using a material with high compressive strength such as tungsten carbide minimizes these changes in balance diameter.

Figure 2: Dynamic secondary sealing system.

Temperature range

Applications as low as -94°F and as high as 482°F commonly use dry gas seals. The standard 90 durometer Viton O-rings employed for secondary sealing elements are rated for temperatures between approximately -40°F to 380°F. Special O-ring material or PTFE sealing elements are used to extend that range.

Just as with pressure, the balance sleeve expands and contracts with temperature changes. The usual industry design incorporates a large clearance between the balance sleeve and the non-rotating seal ring inner diameter. When the seal is cold, however, sealing element extrusion can occur. As the seal temperature rises, insufficient clearance can lock the seal ring and lead to failure. Designs for cold applications incorporate smaller clearances, which increase as the seal cools. But this can also lead to extrusion.

The best approach is to construct the balance sleeve from a carbide material to provide a much smaller clearance change as seal temperature changes. The thermal expansion coefficient between tungsten carbide and silicon carbide is much closer compared to silicon carbide and 410 stainless steel – the typical material combination. An additional tungsten carbide ring supporting the dynamic sealing element further eliminates clearance changes no matter how extreme the temperature change. This design manages temperature ranges from -94°F to +482°F or more.

Face contact

It is detrimental to operate any mechanical seal with no sealing media between the seal ring faces. This causes face contact and leads to a seal failure. Pumps in tank farms are often run dry for extended periods and these seals continuously fail. To manage this problem, a process was developed to grow a layer of diamond on seal ring faces. This layer greatly increases pump seal life. This same technology was applied to dry gas seals to manage face contact.

Dry gas seal ring faces are in contact when inadequate pressure is applied to the seal rings or when a compressor is rotated at speeds below 500 rpm. When a ratcheted compressor or one operating on a turning gear are operated, no seal gap is produced or the sealing media is absent between the seal faces. This leads to contact operating modes.

Even when the compressor is pressurized, the secondary seal still has the possibility of insufficient pressure, leading to face contact. For silicon carbide seal rings, diamond-like carbon (DLC) is applied to the faces. This permits contact operation for small time increments. Seal rings made of tungsten and carbon graphite are more forgiving and can operate for longer periods in contact. The downside to this combination is that the carbon graphite face wears as contact occurs, producing carbon dust. When in contact with dry nitrogen, the graphite face wears even quicker and generates more carbon dust. This has some impact on the flatness of the seal ring face, and negatively impacts seal reliability. The dust collects in the grooves and around the dynamic sealing element, contributing to premature failure.

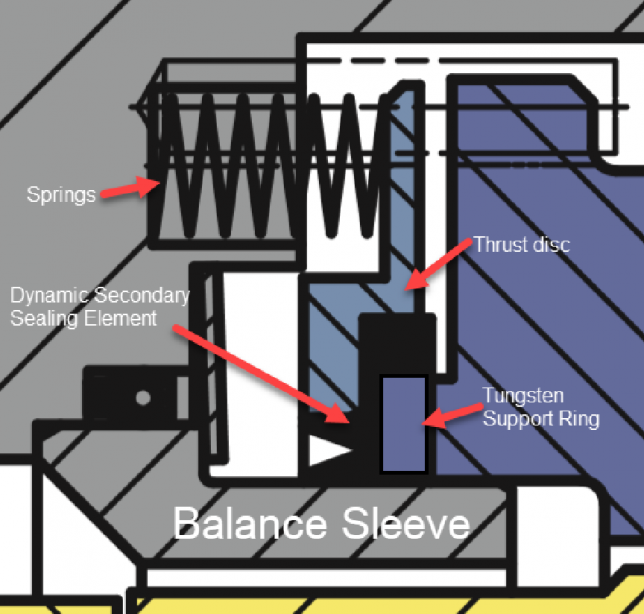

To effectively manage long periods of face contact, a diamond coating is applied to the seal ring faces (Figure 3). This increases seal life due to its hardness, low friction coefficient and heat dissipation. These traits prevent any detrimental effects when seal ring faces operate in contact.

Figure 3: Diamond-coated seal ring.

Leakage

There are many factors contributing to seal leakage. Seal size, operating speed, operating pressure, operating temperature and seal media are dictated by the application and the compressor. Groove geometry, seal ring material, and seal gap are all part of seal design and controllable or changeable by the seal manufacturer.

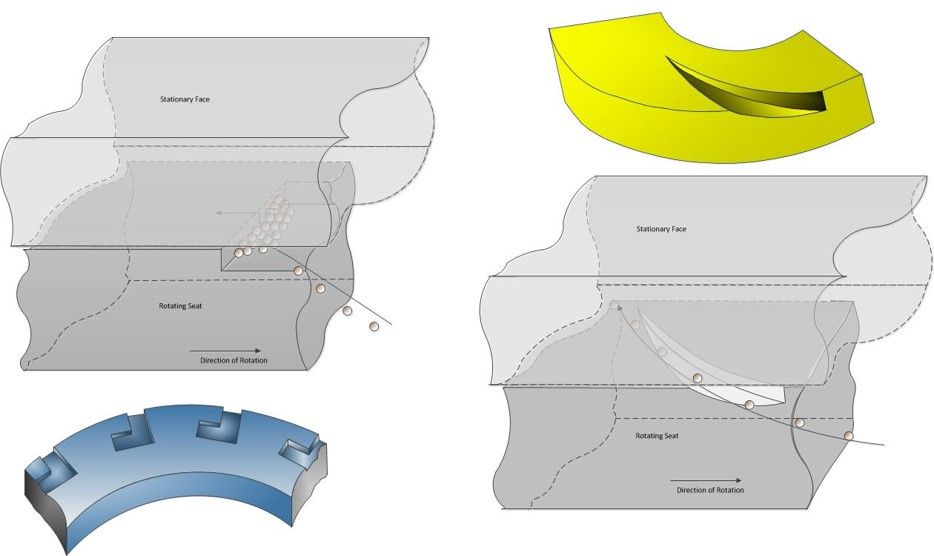

Dry gas seals typically have unidirectional spiral grooves. Manufacturers have identified the spiral groove as the best for producing a stiff gas film to prevent contact between seal ring faces. Through finite element analysis and programming developed to determine how groove geometry effects seal leakage and gap generation, a bidirectional groove has been developed. It produces the lowest leakage, with the higher film stiffness and reliability. If a compressor has been turned backwards inadvertently, this can damage or destroy unidirectional seals. A bidirectional seal eliminates this concern.

A 2-dimensional groove formed in the seal face is the most common profile used in the industry (Figure 4). This produces an edge around the groove that traps debris. As debris builds, the groove becomes ineffective at producing a sufficient gap and gas film stiffness. A 3-dimensional groove with an angled groove profile, on the other hand, allows debris to flow through it without impacting groove effectiveness.

Figure 4: Grooves in a rotating, two-dimensional ring.

Dry gas seals typical operate with a three- to four-micron seal gap. This provides safety to prevent contact between seal ring faces due to any seal ring deformation. If the gap is too small and contact occurs, the seal ring faces are damaged, and failure can result.

Part of a dry gas seal factory test is opening it after the completed testing to check that no marks are visible on the seal faces. This verifies that there is an adequate gap and gas film stiffness to manage any seal face deformation within the designed operating range. The reduction of seal ring deformation is achieved by manufacturing it from silicon carbide. This allows for a reduced seal gap. Using diamond as the coating to dissipate heat generated in the seal gap also reduces seal ring deformation. The combination of a rigid seal ring, a 3-dimensional, bidirectional groove and a diamond coating, results in the lowest achievable dry gas seal leakage.

Separation seal

Liquids must be kept away from a dry gas seal to work effectively. As fluid film bearings lubricated with oil are next to the seal, it is crucial to ensure no lube oil enters the seal. Process gas, too, must not enter the bearing cavity. A separation seal addresses these issues.

Originally a split labyrinth was used. Air or nitrogen is injected into the middle of the labyrinth, so no lube oil migrates into the dry gas seal and process gas is directed out the secondary seal vent. Labyrinths were robust, but didn’t always prevent oil in the dry gas seal or process gas in the lube oil system. Carbon ring seals were a better fit, but experienced similar challenges to labyrinths. Carbon rings also had a lower mean time between repairs than the dry gas seal.

A coaxial barrier seal (Figure 5) was developed to overcome separation seal shortfalls. This end face seal eliminates the direct flow path from the lube oil cavity to the dry gas seal cavity or visa-versa. Reliability, lifespan and safety are all improved while reducing separation seal gas consumption.

Figure 5: EagleBurgmann CobaSeal Coaxial Barrier Seal.

Sealing media

It is not always possible to prevent liquids entering or forming in a seal. Process gas, for example, can be exposed to ambient temperature and can drop in pressure and temperature as it flows from the compressor supply takeoff, through the seal gas supply system and across the seal faces. Exposure to these conditions can cause a component in the gas to change its phase to liquid. Seal failures have occurred due to phase change.

Gas conditioning is incorporated into seal gas supply systems to prevent liquid from entering the dry gas seal. But this adds to operating costs. Ideally, a seal should function even when liquid is present. Liquid, though, takes more energy to sheer than gas. Sheering produces heat. Heat, in turn, deforms the seal faces, which causes contact. This creates more heat and face deformation, which leads to a seal failure. Additionally, when a compressor stops, liquid between the seal rings creates a bond. High torque is required to break this bond. This can damage a seal ring.

A seal design to work effectively with a dual phase gas must:

• Reduce torque to break the liquid bond

• Reduce seal ring impact forces from drive and anti-rotation pins

• Reduce heat generation

• Prevent heat buildup.

3-D grooves reduce the torque required to break the liquid bond between seal rings. Flexible or soft torque anti-rotation and drive pins reduce impact forces that damage a seal ring. Diamond coated silicon carbide reduces heat buildup and conducts it away. Incorporating these features enables a seal to operate with gas, dual-phase gas and liquid. The only requirement of this new seal design is for the sealing media (gas, dual phase gas or liquid) to contain no larger than three-micron particles. This provides a user reliable seal operation. ■

By Glenn SchmidtGlenn Schmidt is Senior Sales Director for Turbomachinery Solutions at Eagle Burgmann, a manufacturer of dry gas seals and other sealing, coupling and expansion joint products. For more information, visit EagleBurgmann.com