LNG Sparks Turbomachinery Growth

Modularization, renewable natural gas, and decarbonization are among key trends spurring growth.

Companies in the power generation and energy sectors are adapting to recent changes in the landscape. Some segments of the market are taking them on better than others. One success story is that of LNG. Expanding infrastructure for LNG requires increased compressor optimization to handle higher volumes of gas more reliably. Heat recovery steam generators (HRSGs,) too, are in greater demand since they decrease plant energy consumption per ton of LNG produced. Onshore and nearshore LNG applications are adapting to decarbonization initiatives. These and other trends are discussed below to highlight the various ways companies are tackling challenges related to LNG production, transportation, utilization, development, and decarbonization.

SIEMENS ENERGY

Patrice Laporte, Vice President of Sales Compression Americas, Siemens Energy, outlined how the company offers high-speed reciprocating, process reciprocating, and centrifugal compressors. Driven by the shifting energy map of Europe and the Inflation Reduction Act in the United States, the market currently sees significantly increased demand for LNG, CO2, and hydrogen. For CO2 applications, integrally geared compressors are seeing an increased need to modularize the package to reduce lead times. The hydrogen market is also picking up. Generally, the entire gas value chain is driving higher demand.

“Special attention is required for the compressor aerodynamic path design and its integration to the overall LNG plant to meet performance requirements.” said Patrice Laporte, Siemens Energy.

One of the most significant use cases for compressors is in refrigeration. For main refrigerant (MR) applications, compressors increase the pressure of the refrigerant employed to meet process conditions. Depending on the technology employed, normal operating conditions have pressures that can go approximately above 60 bar/870 psi and temperatures as low as -30 °C/-22°F. This machinery operates continuously and is the largest power consumer and operating expense contributor in an LNG plant. Special attention is required for the compressor aerodynamic path design and its integration to the overall LNG plant to meet performance requirements.

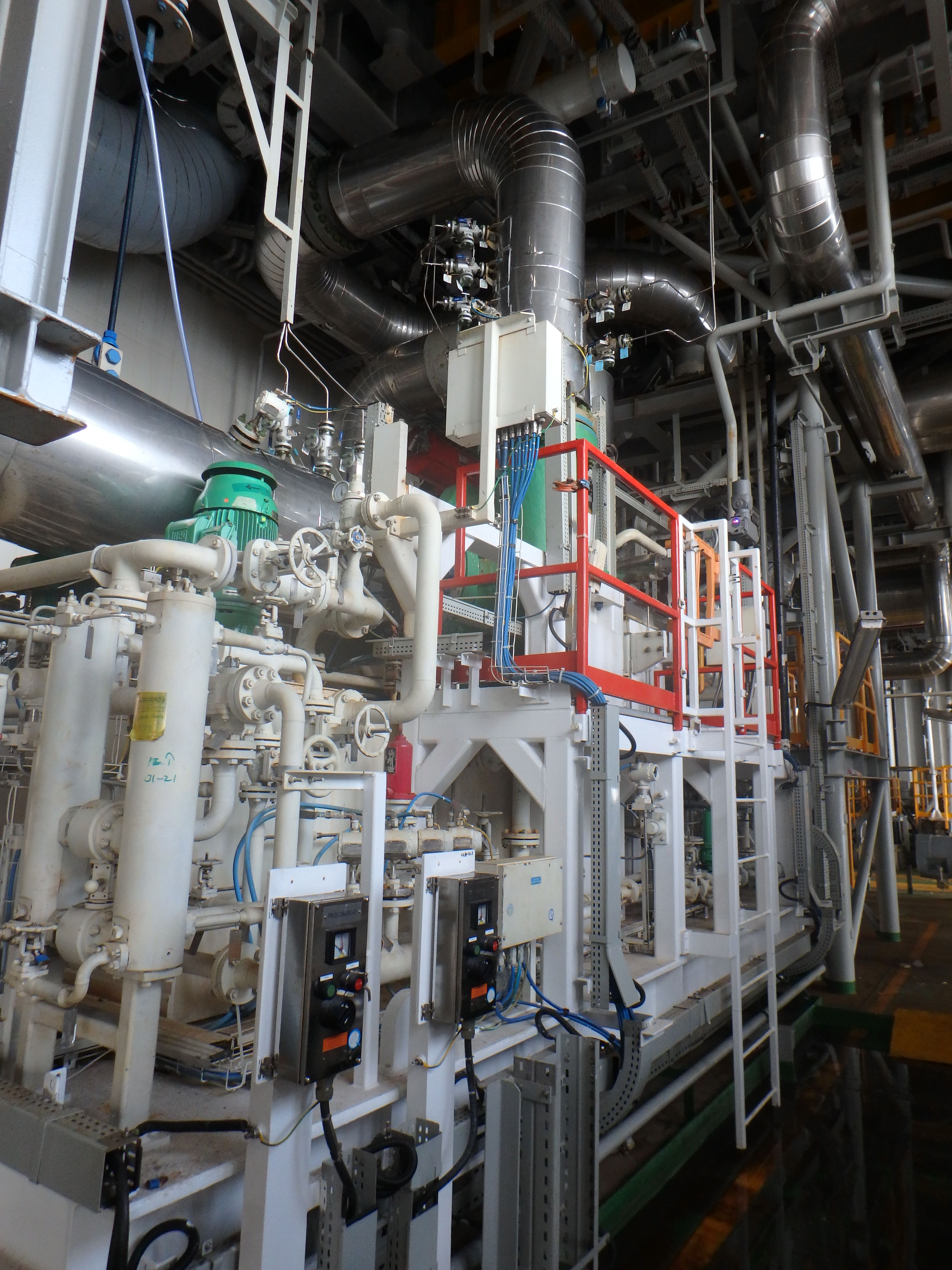

Single shaft horizontally split compressor casings, such as the above, are suitable for boil off gas trains. Courtesy of Siemens Energy.

Boil-off-gas (BoG) involves pressurizing vapor byproduct through a compressor that is developed throughout the LNG process and storage units. For this use, LNG vaporizes through expansion and heat input with temperatures as low as -160°C/-256°F. Emissions are one of the top priorities in the conversation of plant operations.

There is debate about using e-LNG compression trains over gas turbines to support emission reductions efforts and decarbonization solutions, particularly for onshore and nearshore LNG. Smaller-scale solutions at 2 MTPA and lower are becoming more prevalent due to faster project duration from the final investment decision (FID) to first LNG production, said Laporte. Further implementation of Voltage Source Inverters (VSI) versus Load Commutated Inverters (LCI) drives helps reduce inter-harmonics. It should be noted that power limitations of large VSI drive systems are becoming less of an issue and will soon be comparable to LCI. Variable Frequency Drive (VFD) systems allow speed control during operation and transient events. Electrical drives are advantageous as they enable independent power and speed manipulation, extending operational capabilities.

ROTOFLOW

Rotoflow has a significant stake with turbomachinery utilization in LNG. The company’s ETAC high-pressure turboexpander line provides refrigeration for air separation and liquefaction facilities around the world. The expander compressor has impeller sizes of 3.5” to 22” and power from 4 to 14,000 kW. However, larger impellers and powers have been adapted. The largest impeller deployed by Rotoflow to date has a diameter greater than 50”, said Bradford Jeanes, Rotoflow Proposal Manager, New Equipment & Product Technology.

Several Rotoflow compander models have been marinized or specifically tailored for coastal or offshore applications, as seen in this FLNG facility, to withstand the harsh and corrosive saltwater environment. Courtesy of Rotoflow.

Jeanes called attention to the promise of small-scale LNG. Rotoflow’s ETAC-16R high-pressure compander products are used in a variety of LNG facilities, whether land based or floating vessel. One project currently underway is the manufacturing of a large number of high-pressure turboexpanders for an LNG producer in Qatar. Rotoflow’s compander is part of its small-scale LNG (ssLNG) peak-shaving product offering. The ETAC-7R, 8R, and 10R frame models are typically used in peak shaving applications to meet demand spikes. LNG can be seen as the balanced choice between environmental and efficiency considerations, said Jeanes. Demand for clean fuels such as LNG is high right now and for the foreseeable future, he added.

“The largest impeller deployed by Rotoflow to date has a diameter greater than 50”, said Bradford Jeanes, Rotoflow.

Other ways Rotoflow works with LNG are through its ssLNG product line. It offers nitrogen-based refrigeration cycles with an established reference base. Rotoflow is partnering with Air Products’ LNG business, providing new frame solutions (EC-30s and EC-40s) for ssLNG plants. Rotoflow sees LNG as a keystone in developing lower carbon, cleaner energy, without compromising production capabilities.

FS-ELLIOTT

FS-Elliott offers centrifugal compressor products used in support of LNG production. Its PAP Plus compressor product line is used in LNG and similar applications, according to Dominic Sarachine, Product Manager, Engineered and Air Separation, FS-Elliott. The company’s design philosophy advocates accessibility while meeting specific industry, customer, and site requirements.

The PAP Plus compressor has a completely removable air-end and horizontally split gearcase design. Customization is one of its prime advantages. The product line provides continuous compressed air for instrument air, plant, and process air compressor applications in LNG plants. Compressor capacities start at around 1,000 cfm (35 m3/min) and reach up to 25,000 cfm (700 m3/min). Steady and reliable compressed air is needed to curtail unplanned downtime, said Sarachine. PAP Plus compressors also accommodate site-specific needs, including human factors engineering (HFE) requirements, or hazardous area requirements for operator and plant safety. Operating conditions always need to be considered. Advances in technology mandate continued evaluation of site productivity capabilities.

This compressor package for a Middle Eastern oil refinery features an instrument rack with transmitters for local monitoring and a walkway platform for maintenance access. Also included are fan-cooled air-to-air heat exchangers for cooling between compressor stages. Courtesy of FS-Elliott.

Sarachine noted that LNG plants tend to reach high operating efficiencies while working at rated conditions. These capabilities depend on practical aerodynamic and mechanical design expertise. LNG today is more focused on equipment performance across wider operating conditions when designing and operating plants, he said. This improved efficiency can contribute to emission reduction. Achieving a broader flow and pressure range while maintaining the greatest efficiency does not necessarily require new impellers, casings, or motors. Simply utilizing the latest advances in control system technology can broaden the operating range of a machine. For example, FS-Elliott’s Regulus Control System offers an energy advisor system to provide operators with recommendations on improving efficiency and a data-driven predictive maintenance module to notify when restorative actions are necessary. Web-based remote monitoring provides a look at compressor health. It’s all part of the bigger conversation on digitalization, paving the way for increasingly accurate and effective measurements.

“LNG is now focused more on equipment efficiency across wider operating conditions when designing and operating plants. This improved efficiency can contribute to emissions reduction,” said Dominic Sarachine, FS-Elliott.

MAN ENERGY SOLUTIONS

Christian Brotel, Head of Sales Industries, Midstream at MAN Energy Solutions touched on the versatility of LNG in meeting new emission requirements. Some of MAN’s most popular compressor models are horizontally split or barrel-type. These centrifugal compressors are used in chemicals, exploration, production, industrial gases, and more. The models cover a wide range of flow rates along with high discharge pressures. The modular configuration includes predesigned and customizable centrifugal compressor packages.

One special offering of MAN is in Factory LNG. The company’s solution is a small-footprint, modularly scalable liquefaction technology based on the HOFIM emission-free compressor, which allows liquefying natural gas locally for storage, transport, and further use in marine, power, and heat generation applications. Through a fleet of cryogenic transport tanks, LNG can be transported over long distances by truck or train to enable the provision of energy to or from isolated regions. LNG links populations or industries with energy sources across distances where pipeline transport is not available or not feasible. Adaptability is part of why natural gas remains one of the world’s top energy resources.

Barrel-type (RB) compressor by MAN Energy Solutions.

One way LNG is being produced is in the process of biogas refining. Brotel expects that the market share for biogas will grow. Utilizing Factory LNG technology at large organic waste collection sites, biomethane—or renewable natural gas (RNG)—can be liquefied from biogas. Biogas or biomethane can be used for combined heat and power (CHP) operations or converted into electricity.

“LNG links populations or industries with energy sources across distances where pipeline transport is not available or not feasible”, said Christian Brotel, MAN Energy Solutions.

When considering the flexibility to connect existing gas consumers with new or remote energy sources, including the growing renewables sector, further LNG development seems logical. However, there are other factors at play. A boom will require the adaption and expansion of gas transportation and storage infrastructure. The focus on electrification and emission reduction of compressor equipment means HOFIM and MOPICO hermetically sealed compressors will see more action, according to Brotel.

MITSUBISHI HEAVY INDUSTRIES COMPRESSOR

Mitsubishi Heavy Industries (MHI) Compressor (MCO) was established in 2010 as a dedicated compressor company under MHI. Takashi Niiyama, Group Manager, Project Development Group, Business Development Division at MCO, highlighted the company’s work in energy transition related markets, such as carbon capture and storage (CCS), carbon capture and utilization (CCU), blue and green ammonia, and hydrogen. The technology used evolved within the conventional fields of ammonia and urea, ethylene/propylene, and propane de-hydro plants. MCO produces large compressor casings with consistent rotor stability. Multi-shaft integrally geared compressors are also available in the MCO portfolio, seeing frequent use in CCS and CCU.

Illustration of a refrigerant compressor driven by a 120 MW dual shaft gas turbine. Courtesy of MCO Compressor.

MCO designs and manufactures LNG mixed refrigerant (MR) compressors according to licensor requirements. For large LNG liquefaction trains, it offers MR compressor packages utilizing the H-100 gas turbine. This grants variable speed operation in a twin shaft design and simplifies plant configuration and start-up, said Niiyama. Full load string tests are done at their Hiroshima facility before shipment to minimize equipment nonconformities. As for mid-scale & small-scale LNG trains, MCO can offer an e-motor drive solution. MCO supplies auxiliary compression services at LNG facilities, such as EFG, booster, and regen applications.

“New requirements are leading to alternative approaches in operation and execution in the LNG compressor market”, said Takashi Niiyama, MCO.

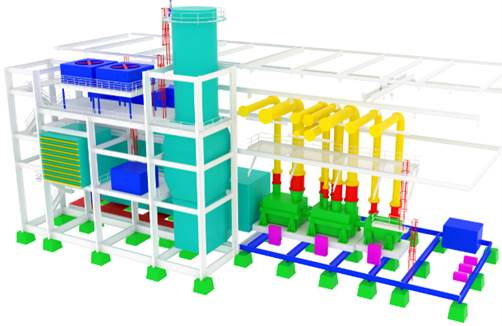

New requirements bring about alternative approaches in operation and execution in the LNG compressor market, said Niiyama. For example, minimizing site work from a construction stand-point and decarbonization trends. Looking ahead, the number of projects adopting modularization philosophies and/or applying e-motor driver in MR compressor strings is increasing.