METHANE CAPTURE

HOW THE INDUSTRY IS DEALING WITH NEW METHANE REQUIREMENTS

Methane from flaring, leakage, and other fugitive emissions is now public enemy number one on the environmental front. Courtesy of Shutterstock

The U.S. Environmental Protection Agency (EPA) and other regulatory bodies around the world are turning their attention to the policing of fugitive emissions from sources such as fuel leakage, unburned methane, and other greenhouse gases (GHG) sources besides those related directly to the combustion process. A big reason for the surge of interest in methane is that it is said to be anywhere from 20 to 90 times more potent than carbon dioxide as a GHG (depending on the time frame considered). Thus, it has been labelled as environmental danger number one.

The Inflation Reduction Act, for example, reduced the amount of allowable methane leakage to 1% and placed a fee of up to $1,500.00 per ton for excess methane. Canada, too, has passed methane emissions reduction rules for upstream oil and natural gas facilities. These encompass extraction, primary processing, transport, storage, leakage from compressors, and fracked gas wells.

Natural gas producers, transporters, plant operators, and the industry in general, therefore, can expect the pressure to ramp up on the monitoring, measurement, and capture of fugitive methane emissions. Previous efforts centered around the minimization of methane flaring. The latest rules, standards, and net zero commitments take things to a whole new level.

The vendor community is responding. Solutions are coming to market that measure the amount of methane that spills out from oil & gas sites, detect various sources of fugitive emissions, capture any leaked methane and reuse it in combustion and other processes, and provide better sealing technology for pipelines and compressors. It is becoming important, too, to be able to report how much methane comes into a facility and compare it to how much is burned and recaptured.

“Natural gas, which is primarily composed of methane, has been regarded as a pollutant as well as a commodity since 2016 based on standards targeting oil & gas operations,” said Brian Kromer, Managing Director and Principal, Step2Compliance. “Controls must now be able to accurately calculate GHG emissions as well as the conventional pollutants. Facilities must learn to track the amount of methane leakage and find ways to recapture it and put it to use.”

Some are even flying airborne infrared spectrometers over oil & gas production basins in attempt to quantify methane point sources. They measure wavelengths in light to estimate the amount of methane. Some say their estimates are questionable. But inflated or not, they will be used to condemn production facilities. The best response is to do everything possible to prevent leakage.

Here are some of the things the vendor community has evolved to address this issue:

EAGLEBURGMANN

EagleBurgmann has developed RoTechBooster technology to reduce methane emissions. If compressors are stopped frequently, dry gas seals may become contaminated. This can be avoided by depressurizing the compressor housing. However during this process, large amounts of methane can escape. To avoid this and maintain pressure in the compressor housing during downtime, a rotating seal gas booster can be used such as RoTechBooster. It is an electrically driven seal gas booster that keeps dry gas seals clean during standby conditions, and at any time insufficient seal gas flow occurs. Its rotating design allows the compressor to be placed in a pressurized hold for nearly unlimited time. No venting or flaring is required.

The company has also released the CobaDGS zero emission compressor seal. In higher pressure applications such as natural gas compressors, conventional tandem dry gas seals are typically used to minimize leakage of natural gas/methane. Due to their tandem design, they meet safety requirements, and reduce emissions by up to 90% compared with oil-lubricated compressor shaft seals. In addition, less friction occurs, and the service life is longer. Nevertheless, tandem dry gas seals still leak some methane into the atmosphere during operation. Another possibility to eliminate seal leakage is to use dry gas seals in double arrangement supplied with nitrogen (N2). However, this seal configuration is less safe and only approved for low pressures. Besides, if the N2 supply is interrupted, the double seals can get damaged.

“For the CobaDGS dry gas seal, EagleBurgmann adapted the coaxial design of its CobaSeal for use at higher pressures,” said Benjamin Hellmig of EagleBurgmann. “The Cobaseal is a separation seal is a coaxial design that is also supplied with N2 but is resilient to gas supply interruptions. It can remain pressurized with N2 during operation and shutdown without contamination.”

MAN ENERGY SOLUTIONS

Matthias Grapow, Vice President Business Intelligence and Business Development, MAN Energy Solutions, believes that producing biogas from organic waste will grow rapidly in the coming years. The company’s HOFIM-based Factory LNG technology is used at organic waste collection sites where biomethane (aka renewable natural gas) can be liquefied from biogas. Biogas or biomethane can be used for combined heat and power (CHP) operations or turned into electricity. This approach can also be used for small-scale LNG to enable natural gas to be supplied to places not directly tied to a mainline natural gas pipeline.

HOFIM high-speed oil-free integrated motor-compressor by MAN Energy Solutions

“Through a fleet of cryogenic transport tanks, the produced LNG can be transported over long distances by truck or trains to enable the provision of energy to isolated regions,” said Grapow.

The hermetically sealed and electrically driven compression HOFIM consists of a single rotating element, two radial and one axial bearing, no couplings, no gearbox, no lube oil and no shaft seals to atmosphere. These zero emission compressors are suitable for use in midstream gas transport, gas storage, small-scale LNG, upstream subsea, and topside compression.

“Instead of flaring production-related gas losses, the gases can be reused within the process for power or heat generation, or can be converted into transportation fuel or LNG,” said Grapow.

BAKER HUGHES

Tom Harper, Vice President, Emissions Management and Commercial Development Leader, Climate Technology Solutions at Baker Hughes, believes that the global oil and gas industry can eliminate 40% of its methane emissions at no net cost. It has developed various tools to meet this challenge.

The company’s Lumen Terrain and Lumen Sky technologies, for example, use analytics to detect, localize, and quantify methane leaks. This information can be used to prioritize recommendations for abatement, as well as supporting the verification of emissions reductions.

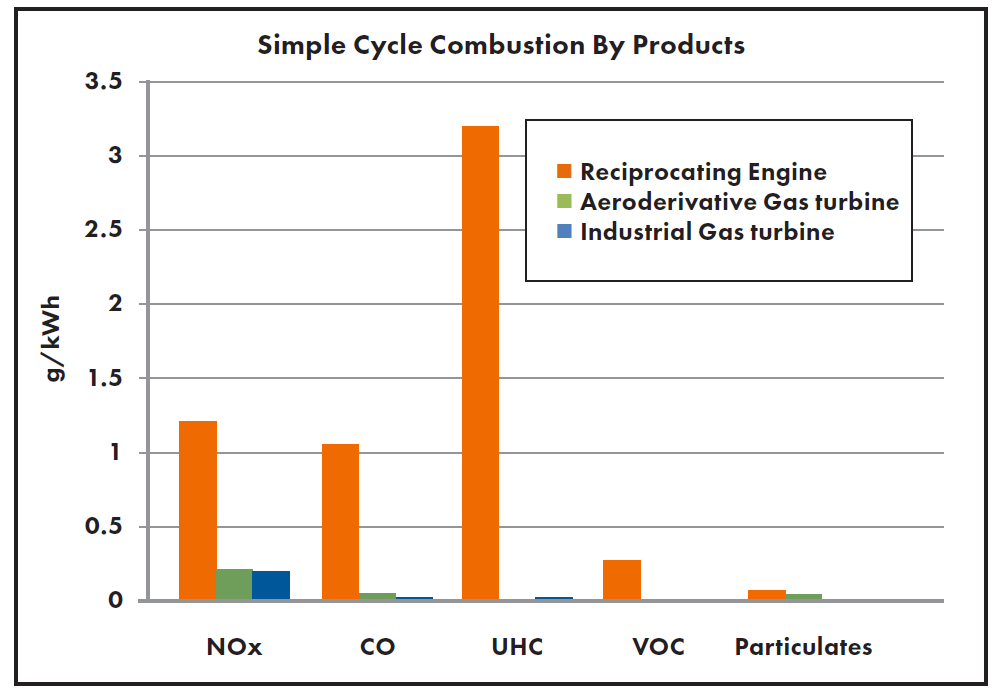

The emissions profile of gas turbines, particularly methane emissions is much better than reciprocating engines. Courtesy of Siemens Energy.

Another abatement solution is flare.IQ. It enables higher-efficiency flare combustion and reduced methane slip emissions. The Egyptian Ministry of Petroleum and Mineral Resources is deploying it in the refining sector in Egypt.

“This will lower flaring emissions from oil and gas operations by digitalizing emissions management infrastructure and pulling information about flare systems, substantially reducing emissions by ensuring a higher-efficiency flare combustion rate,” said Harper.

SIEMENS ENERGY

Siemens Energy’s flagship methane offering is the Spontaneous Leak Detection Service (powered by ProFlex) for gases, liquids and multi-phase fluids transported through pipelines. It utilizes signal processing on edge computing devices, Internet of Things (IoT) software, and data processing algorithms to identify leaks in near real-time.

“Our technology can detect leaks as small as ½ inch to 2 inches within seconds and provide accurate localization to as little as +/- 20 feet, while minimizing false positives,” said Anand Sengupta, Vice-President, Head of Global Sales,

Siemens Energy Compression.

The company has also developed predictive analytics technologies and digital twins that are used in Predictive Emissions Monitoring Software (PEMS) across the Siemens Energy small gas turbines portfolio. It helps operators predict regulated emissions accurately.

“Although methane slip or unburned hydrocarbons (UHC) in the exhaust of gas turbines is orders of magnitude lower compared to other engines, we’ve received many queries from customers, and are planning to incorporate the prediction of UHC into PEMS for small gas turbines,” said Sengupta

OTHER VENDORS

ABB has released of HoverGuard, an addition to its ABB Ability Mobile Gas Leak Detection System. HoverGuard is an Unmanned Aerial Vehicle (UAV)-based system that detects, quantifies and maps leaks up to 300 ft from natural gas distribution and transmission pipelines, gathering lines, storage facilities, and other potential sources. It automatically generates digital reports that summarize results and can be shared in minutes after a survey.

The cloud-connected, multi-gas solution quantifies the three most important greenhouse gases (methane, carbon dioxide and water vapor) continuously while flying. Cavity-enhanced laser absorption spectroscopy detects methane with a sensitivity more than 1,000 times higher than conventional leak detection tools. It can detect leaks while flying at altitudes of 130 ft or higher, and at speeds greater than 55 mph.

FURTHER VENDORS SOLUTIONS

Enclosed Vapor Combustors (EVCs) are available from several vendors. They are being used, for example, in some Canadian gas facilities to address leakage at compressor and meter stations. Burners convert methane into water vapor and CO2. Testing has shown this technology to be 99.6% efficient in converting methane.

Klaus Brun, Director, Research and Development, Elliott Group, said his company is using technologies from others to improve methane emissions along its product line.

“We can utilize leak-free dry-gas seals or seal vent gas capture and recovery when a client requests it,” said Brun. “Our new 140 TCH pipeline compressor has a single dry gas seal instead of two seals to reduce dry gas seal leakage by 50%.”

He noted, though, that the biggest reduction in GHG emissions from compressors can be achieved by improving compressor efficiency or by converting the driver from an engine/gas turbine to an electric motor drive. Another way to lower methane spillage is to avoid shutdowns for blowdowns. That entails improving reliability and availability and eliminating false alarms.

Solar Turbines, too, is doing a number of things to reduce methane emissions. The company uses a system that gathers the leakage from dry gas seals and recompresses it back either to fuel gas pressure or compressor suction pressure.

ExxonMobil has reduced U.S. unconventional methane emissions by approximately 40% as of year-end 2021 when compared to 2016 by conducting tens of thousands of leak surveys and eliminating all its high bleed pneumatic devices. The company has developed ground-based continuous sensors, as well as aerial, airplane and satellites technologies to help with methane reduction.

“By 2030, we’re planning a 20% to 30% reduction in corporate greenhouse gas intensity, a 70% to 80% reduction in corporate methane intensity, and a 60% to 70% reduction in corporate-wide flaring intensity,” said Matt Kolesar, Chief Environmental Scientist at ExxonMobil.

BP has targeted zero routine flaring emissions by 2025 in its U.S. onshore operations and globally by 2030. It is deploying a variety of detection and monitoring technologies and is phasing out remaining pneumatic controllers.

Teledyne Flir’s FLIR GF320 detects hydrocarbon and volatile organic compound (VOC) emissions from natural gas production and use. With this optical gas imaging camera, inspectors can check components and see potential gas leaks in real-time. The GF320 is lightweight, offers both a viewfinder and LCD monitor, and has direct access to controls. Embedded GPS data helps in identifying the precise location of faults and leaks.

The ABB drone can detect leaks and measure gases

Vortex Services of Canada offers the Vortex Emissions Target Solution. It packages a elements that address methane measurement such as a fuel measurement, fuel valves, a display panel, sensors (O2 and NOx) a catalyst monitor, and several venturi elements to improve the fuel/air mix.

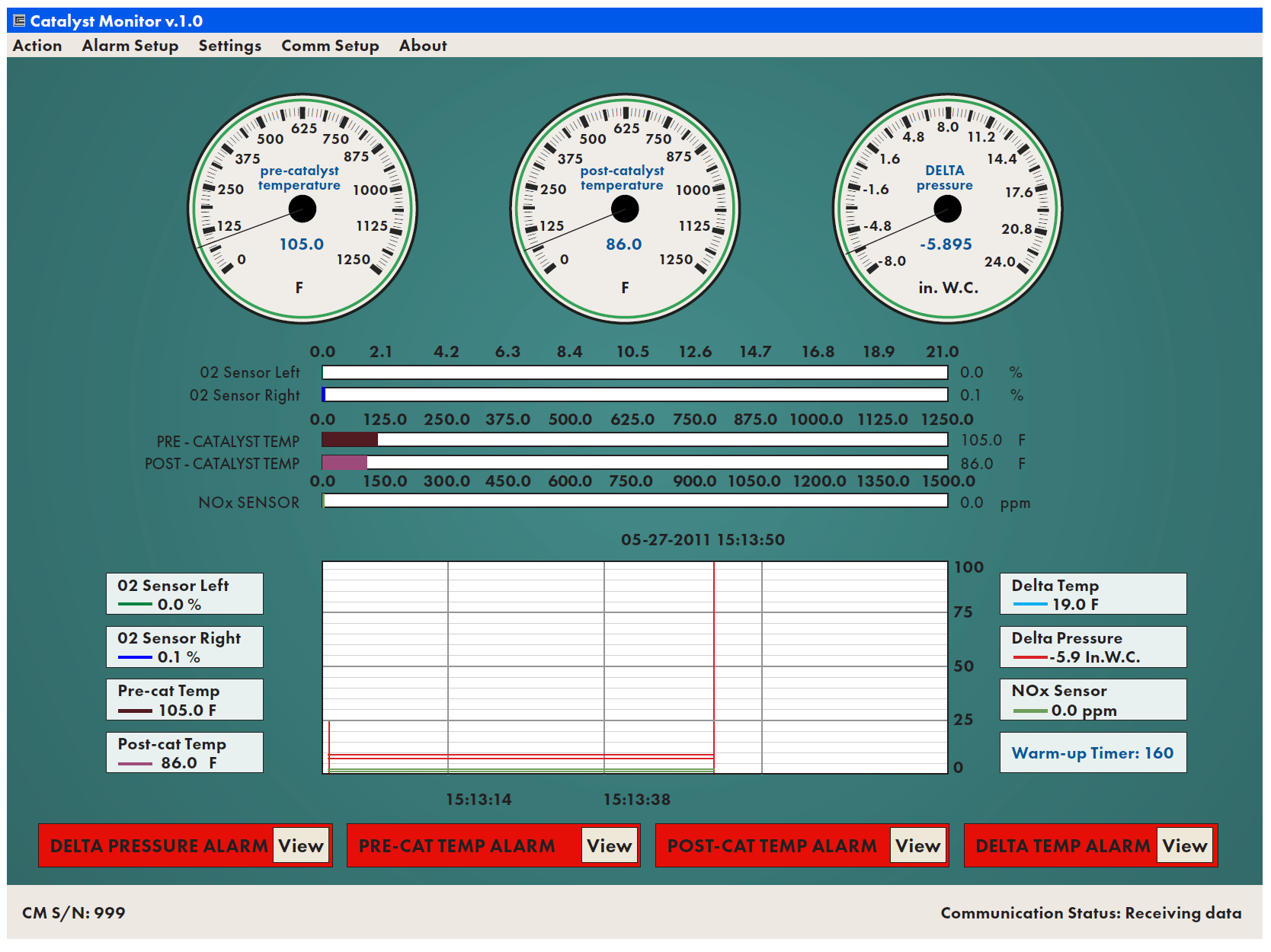

Continental Controls Corp. (CCC) offers a range of fuel control, fuel measurement, and emissions monitoring tools to accurately measure GHGs. Its Catalyst Monitor continuously measures pressure across the catalyst as well as pre- and post-catalyst temperature and notifies the user if minimum or maximum temperatures are exceeded. When combined with the CCC Air Fuel Ratio Controls (AFRC), it can make corrections to set points to maintain low emissions levels and extend the useful life of catalysts. This arrangement can be used to provide evidence of engine compliance and fuel consumption over an extended period of time.

“CCC continuously measures the true rate of methane compliance,” said Kromer. “Its tools can help monitor methane related to the exhaust as well as fugitive emissions.”

The Continental Controls Catalyst Monitor continuously measures pressure across the catalyst as well as pre- and post-catalyst temperature

STRICTER CONTROLS

Utilities, owners, operators, and plant personnel are grooved in to measuring emissions in the exhaust, but not methane.

“Methane is not easy to eliminate and doesn’t go away when you use a three-way catalyst,” said Rick Fisher, Vice President at Continental Controls Corp. “Every compressor station and any plant running a gas turbine or gas engine is going to suffer methane leakage. Even something as simple as a shutting off a valve in a compressor station often leads to some venting of methane.”

Traditional monitors and controls are not set up to accurately measure methane. But owners and operators can expect stricter methane reporting such as on the amount of fuel that comes into a facility, how much was combusted, and how much methane leakage has been collected for reuse. ■