Compressor monitoring and control

TOP TRENDS INCLUDE SOFTWARE-AS-A-SERVICE, INTERNET OF THINGS AND DIGITAL TRANSFORMATION

By Tim Shea

Compressor monitoring and controls are critical for optimizing the performance of compressors widely used across the oil & gas, refining, chemical and petrochemical industries.

Economic drivers include the growing demand for energy, improving compressor efficiency and increasing production of compressor-related products.

Further drivers include emerging Industrial Internet of Things (IoT)-enabled tools, such as advanced analytics, machine learning, and enhanced communications to enable remote monitoring of compressors and other complex rotating equipment. These will help users realize greater performance, higher compressor uptime, and lower maintenance costs.

In addition to greenfield installations, many legacy control systems will require upgrades to extend the life of the compressor. These upgrades will enhance functionality and boost their performance capability.

Software-as-a-Service

The marketplace for compressors and their related monitoring and controls solutions is now evolving at a face pace. Demand for service-based compressor monitoring and controls is expected to outpace that of hardware- and software-based products over the next five years as a growing number of operators and end users decide to outsource some or all of their compressor monitoring and controls.

This is typically known as Software-as-a-Service (SaaS) or Platform-as-a-Service (PaaS). SaaS is a model where the user buys a subscription-based license. The software itself is hosted in the cloud. Benefits include little or no upfront costs and no need to maintain the software as that is taken care of by the provider.

Most vendors in this space focus on compressor controls. But expect to see more robust growth for systems that have a primary function of monitoring as users seek to leverage Industrial IoT-enabled solutions for asset performance management and compressor optimization.

Most companies today employ on-premise compressor monitoring and controls. A small fraction are hosted by their compressor OEM via a remote service program. The latter segment will experience solid growth.

Similarly, there will be robust growth for the currently tiny share deployed via the cloud. Users are overcoming their fears about operating in the cloud and beginning to embrace the benefits of lower total cost of ownership, more flexible operations, and access to the world-class security and analytics of companies, such as Microsoft, AWS and Google.

The advent of smart, connected compressors is opening the doors to new business models. Suppliers can now become providers of services, such as compressed air-as-a-service or natural gas compression. Many are already offering remote monitoring and control services as users struggle to do more with fewer personnel.

Digital transformation

Industrial IoT-enabled tools can provide business and operational value across many areas. However, rotating equipment, such as compressors, turbines and pumps, represents the lowest hanging fruit for operators and end users.

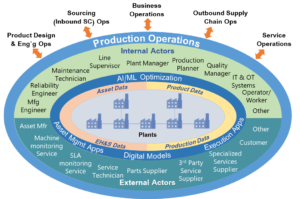

Compressor monitoring and controls solutions are increasingly being updated with new features to fulfill market demands and increase their value proposition. Smart Industrial IoT-connected compressors provide opportunities to increase operational efficiency from the plant floor (or the platform) to the supply chain by optimizing data, information and analytics. In the centrifugal compressor space, for example, monitoring and control packages are focusing on several areas:

• Pushing out performance of the surge line

• Reducing instances of stall

• Optimizing load distribution

• Using analytics to help optimize centrifugal compressor performance and increase or extend the life of the compressor.

Data gathering and communication capabilities via standard networking technologies are built-in features of some compressor monitoring and controls solutions. With the Industrial IoT, smart compressors could improve industrial processes. This, in turn, would drive the use of more automation.

In addition, the Industrial IoT offers opportunities to apply new kinds of business models that will promote growth. Suppliers in this space may start selling contract compression services along with compressor hardware or could partner with compressor manufacturers or packagers to offer remote monitoring and control services for a monthly or yearly fee.

As the shift to LNG from oil grows and demand for natural gas grows, the need for compression will increase. Downstream manufacturing operations have become increasingly dependent upon the performance and availability of compressors.

To increase availability, monitoring and controls providers need to incorporate technological innovations, such as Industrial IoT, to increase reliability, optimize load control, and ― for centrifugal compressors ― operate closer to their maximum designed performance or surge line.

Continuing innovation in sensors, embedded control algorithms and predictive condition monitoring are critical to the future of smarter compressors. Some users are specifying future-proof compressor monitoring and controls that are Industrial IoT-ready.

In addition, the growing adoption of cloud- and edge-based solutions will help optimize compressor performance. Digitally enabled approaches that leverage artificial intelligence, machine learning, enhanced communications and software can go a long way towards realizing operational excellence.■

Tim Shea is Senior Analyst at ARC Advisory Group in Dedham, Massachusetts, a company specializing in technology market research firm for industry, manufacturing, infrastructure and cities. For more information on ARC’s recently published Compressor Monitoring & Controls Market Analysis Report, contact tshea@arcweb.com

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)